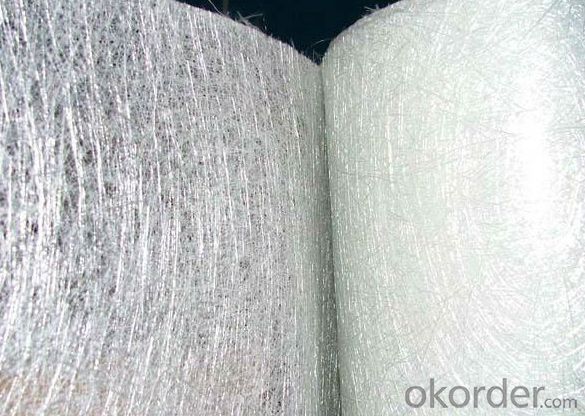

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 2200mm

Our chopped strand mat is with width 2200mm, packing in wooden box (pallet)with width 2250mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

2.Main Features

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q:How is fiberglass mat tissue used in the production of storage containers?

- The unique properties and benefits of fiberglass mat tissue make it a common choice in the production of storage containers. This thin layer of non-woven glass fibers offers excellent strength and durability, reinforcing the structure of the containers and ensuring they can withstand heavy loads without deforming. In addition to its strength, fiberglass mat tissue is highly resistant to corrosion, moisture, and chemicals. This makes it perfect for storage containers that may be exposed to harsh environments or contain corrosive substances. By acting as a protective barrier, the fiberglass mat tissue prevents any potential damage or degradation to the container. Furthermore, fiberglass mat tissue is lightweight, making it easier and more cost-effective to transport and handle during production. It also helps reduce the overall weight of the storage container, allowing for increased payload capacity and more efficient storage and transportation. During the molding process, the fiberglass mat tissue is typically applied to the surface of the container. It is often impregnated with a resin or adhesive, which, when cured, creates a strong bond with the container, enhancing its structural integrity. Overall, fiberglass mat tissue is crucial for the production of high-quality and long-lasting storage containers. Its strength, durability, corrosion resistance, and weight reduction capabilities make it the preferred choice for manufacturers in this industry.

- Q:What are the typical roll sizes available for fiberglass mat tissue?

- The manufacturer and specific application determine the varying sizes of fiberglass mat tissue rolls. Generally, they range in width from 50 inches to 120 inches and in length from 100 yards to 1,000 yards. These sizes are frequently utilized in construction, automotive, and marine industries for purposes such as insulation, reinforcement, and soundproofing. It should be emphasized that the availability of particular roll sizes may vary depending on the supplier and the intended use of the fiberglass mat tissue.

- Q:How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q:How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue performs exceptionally well in terms of moisture absorption. Due to its composition of multiple layers of glass fibers and a binder, it can effectively resist moisture penetration, making it highly resistant to water absorption. This property makes fiberglass mat tissue an ideal material for various applications where moisture resistance is crucial, such as in roofing, insulation, and composite manufacturing.

- Q:How does fiberglass mat tissue perform in high temperatures?

- Fiberglass mat tissue performs well in high temperatures due to its inherent heat resistance properties. The mat is typically made from glass fibers that are woven together, creating a strong and durable material. These glass fibers have a high melting point, allowing the fiberglass mat tissue to withstand elevated temperatures without deforming or losing its structural integrity. When exposed to high temperatures, fiberglass mat tissue does not shrink, warp, or become brittle like other materials might. It retains its dimensional stability and mechanical strength, making it suitable for various applications in industries such as automotive, aerospace, construction, and insulation. Additionally, fiberglass mat tissue acts as a thermal insulator, offering protection against heat transfer. It can effectively resist heat conduction and radiation, helping to maintain the desired temperature in a given environment or prevent heat damage to surrounding components. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not burn or produce toxic gases when exposed to fire. This makes it a reliable choice for applications that require fire resistance, such as fireproofing insulation or protective barriers. In summary, fiberglass mat tissue performs exceptionally well in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature make it an excellent material for use in demanding environments where elevated temperatures are present.

- Q:How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue directly affects its performance. A thicker tissue provides increased strength, durability, and insulation properties. It also enhances the material's ability to absorb impact and resist damage. Thinner tissues, on the other hand, offer greater flexibility and easier handling. Therefore, choosing the appropriate thickness of fiberglass mat tissue is crucial to achieve desired performance characteristics in various applications.

- Q:Can fiberglass mat tissue be used for composite tooling?

- Composite tooling can utilize fiberglass mat tissue, a lightweight material formed from randomly arranged strands of fiberglass that are bonded together with a resin binder. This material is commonly employed in composite applications like boat construction, automotive components, and aerospace structures, serving as a reinforcement material. Utilizing fiberglass mat tissue for composite tooling can bring about increased strength and stiffness to the structure of the tooling. By layering and impregnating the mat tissue with resin, a sturdy and long-lasting composite tool can be formed. The resin binder in the mat tissue aids in holding the fibers together and offering resistance against wear and tear. Additionally, fiberglass mat tissue is malleable and easily molded into intricate shapes, making it suitable for crafting tooling with complex designs. It can be effortlessly cut and shaped to match the desired dimensions of the tooling. Nevertheless, it is crucial to acknowledge that fiberglass mat tissue alone might not meet the requirements of all tooling applications. Depending on the specific demands of the tool, additional reinforcement materials like carbon fiber or Kevlar may be necessary to augment strength and durability. To summarize, fiberglass mat tissue presents a cost-effective and practical option for composite tooling, bestowing strength, flexibility, and user-friendliness.

- Q:What is the expected lifespan of fiberglass mat tissue in underground applications?

- The expected lifespan of fiberglass mat tissue in underground applications can vary depending on various factors such as the specific conditions of the underground environment, the quality and thickness of the fiberglass mat tissue, and the level of maintenance and care provided. However, on average, fiberglass mat tissue is known for its durability and longevity, making it suitable for underground applications. In general, fiberglass mat tissue is designed to be highly resistant to corrosion, moisture, and other environmental elements commonly found in underground settings. This makes it a reliable choice for applications such as underground pipes, tanks, and other infrastructure where protection against deterioration is crucial. With proper installation and regular maintenance, fiberglass mat tissue can have an expected lifespan of 50 years or more in underground applications. However, it is essential to note that this estimate can vary depending on the specific conditions and usage of the fiberglass mat tissue. To ensure the maximum lifespan of fiberglass mat tissue in underground applications, it is recommended to follow industry best practices, such as proper installation techniques, regular inspections, and addressing any issues, such as cracks or damage promptly. By doing so, the lifespan of fiberglass mat tissue can be extended, providing long-term reliability and durability in underground settings.

- Q:Can fiberglass mat tissue be used for insulation in power generation facilities?

- Yes, fiberglass mat tissue can be used for insulation in power generation facilities. Fiberglass mat tissue is a versatile material that is commonly used for insulation purposes due to its excellent thermal and electrical insulation properties. It is resistant to high temperatures and can effectively trap and prevent the transfer of heat, making it suitable for use in power generation facilities where heat management is crucial. Additionally, fiberglass mat tissue is lightweight, easy to install, and offers high durability and longevity, making it a cost-effective choice for insulation in power generation facilities.

- Q:What is the tear resistance of fiberglass mat tissue?

- The ability of fiberglass mat tissue to withstand tearing or ripping when exposed to mechanical stress or force is referred to as its tear resistance. Due to its strong and durable nature, fiberglass mat tissue is renowned for its high tear resistance. This tear resistance is typically quantified and reported as tear strength, which measures the force needed to tear the material. The determination of tear strength involves standardized testing methods like the Elmendorf tear test or the tongue tear test. Various factors, including thickness, density, and composition, can influence the tear resistance of fiberglass mat tissue. Nevertheless, fiberglass mat tissue generally exhibits outstanding tear resistance properties, making it an excellent choice for applications where durability and strength are crucial, such as in the construction industry for reinforcement materials or in the production of composite materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords