Aluminum T-Slot Extrusion Profiles for Embossed Warm Protection CC Aluminum Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

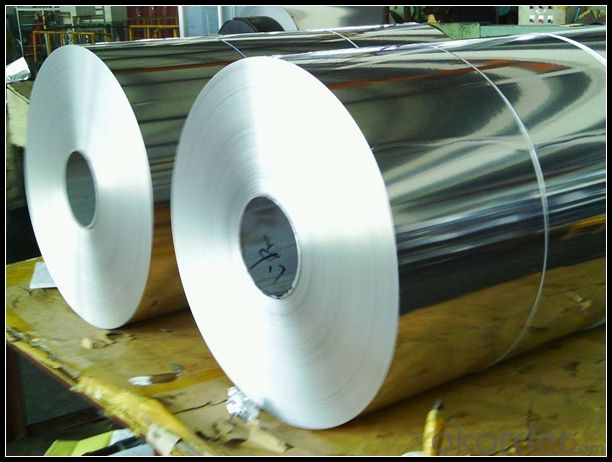

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are the impact resistance properties of aluminum profiles?

- Aluminum profiles have excellent impact resistance properties due to their inherent strength and durability. They can withstand high impact forces without deforming or breaking, making them suitable for various applications where impact resistance is crucial, such as automotive, construction, and aerospace industries. Additionally, aluminum profiles can absorb and distribute impact energy effectively, minimizing the risk of damage or injury.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the construction or design of staircases.

- <p>Aluminum profiles for staircases are diverse and serve different functions. Common types include: 1. Handrail profiles, which provide support and safety. 2. Stringer profiles, forming the backbone of the staircase. 3. Tread profiles, which are the horizontal surfaces on which one steps. 4. Riser profiles, covering the vertical space between steps. 5. Baluster profiles, used as vertical supports between handrails and treads. 6. Connector profiles, for joining different parts of the staircase. Each type is designed to withstand specific loads and is chosen based on the staircase's design, weight capacity, and aesthetic requirements.</p>

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- You mold two boxes connected at a relatively small, may die requirements will be much higher, I do not know whether the price will be more expensive.

- Q: What are the bending radii for different aluminum profiles?

- The bending radii for different aluminum profiles can vary depending on the specific profile shape and thickness. It is important to consult the manufacturer's specifications or engineering guidelines to determine the recommended bending radii for each aluminum profile.

- Q: How do aluminum profiles contribute to sustainable building practices?

- Aluminum profiles play a crucial role in promoting sustainable building practices for several reasons. Firstly, aluminum is a highly recyclable material, meaning that it can be melted down and reused multiple times without any loss in quality. This recyclability greatly reduces the need for extracting and processing virgin aluminum, which is an energy-intensive and environmentally damaging process. By using aluminum profiles in construction, we can significantly minimize the demand for new aluminum production, thus conserving natural resources and reducing carbon emissions. Moreover, aluminum profiles are lightweight yet strong, making them ideal for creating energy-efficient structures. The lightweight nature of aluminum reduces the load on the building's foundation and structural elements, resulting in lower material requirements and reduced construction costs. Additionally, a lighter structure requires less energy to heat and cool, leading to decreased energy consumption and reduced greenhouse gas emissions over the building's lifespan. Furthermore, aluminum profiles have excellent thermal and acoustic insulation properties. When properly utilized, they can contribute to the overall energy efficiency of a building by minimizing heat loss or gain through windows and doors. This translates into reduced reliance on artificial heating and cooling systems, leading to decreased energy consumption and lower utility bills. Additionally, aluminum profiles are highly durable and require minimal maintenance. Their resistance to corrosion, weathering, and UV rays ensures a long lifespan, reducing the need for frequent replacements and repairs. This not only saves resources but also reduces waste generation and landfill usage. Lastly, aluminum profiles offer great design flexibility and can be easily integrated into various architectural styles and designs. This versatility enables architects and builders to create aesthetically pleasing and functional structures that meet the needs of occupants while still adhering to sustainable building practices. In conclusion, aluminum profiles contribute to sustainable building practices by being recyclable, lightweight, energy-efficient, thermally insulating, durable, low maintenance, and versatile. By incorporating aluminum profiles into construction projects, we can reduce our environmental footprint, conserve natural resources, and promote a more sustainable future.

- Q: How do you prevent galvanic corrosion with aluminum profiles?

- To prevent galvanic corrosion with aluminum profiles, there are several steps that can be taken: 1. Use compatible materials: It is important to select materials that are compatible with aluminum to avoid galvanic corrosion. Avoid coupling aluminum profiles with dissimilar metals, such as copper, brass, or steel, as these combinations can accelerate the corrosion process. 2. Apply protective coatings: Applying a protective coating, such as anodizing or painting, can provide a barrier between the aluminum profiles and the surrounding environment. Anodizing creates a durable oxide layer on the surface of aluminum, which enhances its corrosion resistance. Painting with suitable corrosion-resistant paints can also provide an effective barrier against galvanic corrosion. 3. Insulate dissimilar metals: If it is necessary to use dissimilar metals in conjunction with aluminum profiles, it is crucial to insulate them from direct contact. This can be achieved by using gaskets, insulating materials, or non-conductive fasteners to separate the metals and prevent the electrical contact that causes galvanic corrosion. 4. Regular maintenance and cleaning: Regular cleaning and maintenance of aluminum profiles can help prevent galvanic corrosion. Removing any accumulated dirt, debris, or other contaminants from the surface can minimize the chances of corrosion initiation. 5. Control the environment: Controlling the environment in which aluminum profiles are used can also play a significant role in preventing galvanic corrosion. Avoid exposing aluminum to environments with high humidity, saltwater, or acidic conditions, as these can accelerate corrosion. Additionally, maintaining proper ventilation and moisture control can help minimize the risk of corrosion. By following these preventive measures, it is possible to significantly reduce the risk of galvanic corrosion and ensure the longevity and performance of aluminum profiles.

- Q: Can aluminum profiles be used in green building projects?

- Green building projects can utilize aluminum profiles effectively. Aluminum, being an eco-friendly material, offers numerous advantages in the realm of green building. To begin with, aluminum's lightweight nature cuts down on transportation costs and energy consumption during construction. Furthermore, aluminum is entirely recyclable, ensuring that it can be reused indefinitely without any loss in quality. This characteristic makes aluminum an ideal option for green building projects as it aids in waste reduction and promotes a circular economy. Additionally, aluminum boasts a lengthy lifespan and necessitates minimal upkeep, further enhancing its sustainability. It is worth noting that aluminum profiles can easily be integrated with other green building materials like glass, enabling energy-efficient designs that maximize natural light and minimize the reliance on artificial lighting. In conclusion, aluminum profiles offer a sustainable and versatile choice for green building projects.

- Q: Can aluminum profiles be used in the production of transportation containers?

- Yes, aluminum profiles can be used in the production of transportation containers. Aluminum is a lightweight and durable material that is commonly used in the manufacturing industry. It offers excellent strength-to-weight ratio, corrosion resistance, and can withstand harsh environmental conditions, making it suitable for transportation containers. Additionally, aluminum profiles can be easily shaped and welded, allowing for customization and efficient production.

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

- Q: Can aluminum profiles be used for creating lightweight furniture?

- Yes, aluminum profiles can be used for creating lightweight furniture. Aluminum is a lightweight and durable material, making it ideal for furniture design where weight is a consideration. Aluminum profiles can be shaped and fabricated into various furniture components such as frames, legs, and supports. Additionally, aluminum profiles offer excellent corrosion resistance, which is beneficial for outdoor or moisture-prone furniture. The versatility of aluminum profiles allows for the creation of sleek and modern furniture designs that are not only lightweight but also aesthetically pleasing.

Send your message to us

Aluminum T-Slot Extrusion Profiles for Embossed Warm Protection CC Aluminum Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords