Agricultural Irrigation Double Suction water pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

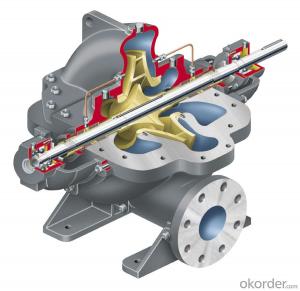

S pump is a single-stage double-suction horizontal split centrifugal pump and used to transport water and the liquid of both physical and chemical nature similar to those of water, the maximum temperature of which must not be over 80°C, suitable for

water supply and drainage in factories, mines, cities and electric stations, waterlogged land drainage and irrigation of farming land and Various hydraulic projects.

Structure

Both inlet and outlet of this pump are placed under the axial line,, the pump casing is opened in the middle so it is unneccessary to remove the water inlet and outlet pipelines and motor.if repaired The pump moves CW viewing from the motor side. The pump moving CCW can also be made .

Both pump casing and cover form the working chamber of the impeller and there are threaded holes for mounting vacuum and pressure meters on the flanges ant both inlet and outlet have water draining plug on the lower side of flange

The impeller is static-balance and dynamic balance tested, fixed by the the side nuts and the Shaft sleeve nuts and its axial position can beadjusted via the nuts and axial force will be get balanced by means of the symmetrical arrangement of its blades, there may be residual axial force which is borne by the bearing at the axial end.

This pump shaft is supported by two centripetal ball bearings, which are mounted inside of the bearing chamber on both ends of the pump and lubricated with grease. The double suction seal ring is used to reduce the leakage..

This pump is driven directly via flexible coupling.(V-belt driving will be available if required).

The shaft seal is mechnicalseal or packing seal .

- Q: I've been noticing a difference in the temperature gage lately. The quot;change oillight has also been coming on and I just had an oil change not even a month ago, and the car isn't even due back for at least another month. I noticed there's a green/blue liquid in my driveway today, too. I looked under the car and something is leaking or dripping around the passengers side front wheel. More so the passenger-middle side. I've been told it could be the water pump.

- you could call your interior reach Dealership and that they supply you the hard artwork for this fix. maximum all shops use the Chilton hard artwork classes for hard artwork time on maintenance. make certain you shop around for sturdy section fees. i advise my consumers to discover this suggestion hard artwork/areas cost. then they are able to call around and shop for the suited cost, if the hard artwork cost is physically powerful however the section is outrageous, then grant the section (do no longer tell the shop which you would be offering the section or they could attempt to advance the hard artwork cost). sturdy success

- Q: Is there a water pump with its own flow regulating function?

- Pump with adjustable flow depends on your useThe ordinary displacement pump, which has a small flow rate, can set the flow rate per second into the system and is widely used in the laboratory.Large flow regulating flow pump is mainly variable frequency pump, through the electrical signal feedback regulation, change the pump water storage flow.The main thing is to see your flow, and then determine what you want to pump!

- Q: PUMP RUNS BUT DONT PUMP WATER

- If you just installed it you may have hooked it up backwards. The intake and output may be reversed or your electrical connection my be opposite what it is supposed to be. Take of the output side and put your finger over it. It should be creating pressure and blow on your finger. If that is not the problem check to see if you have a water filter between the tank and the pump. That my be clogged.

- Q: Does it take more power to pump water with a 1 /12 hp bg motor/pump than one that is a spare pump/motor running dry,not connected to the system? I am trying to figure out how long it will run with an power inverter during a power failure.

- Your Bell and Gosset pump runs on 110 volts and circulates the water through the heating system. It will not run dry because the motor is seperate and spinning an impeller.I don't understand what you are trying to accomplish.

- Q: Why does the pump decay when connected in parallel?

- Because a water pump has reached the rated parameters, the parallel is only "superfluous".

- Q: Where can I get supplies to build water pumps, for decoration.Thank you.

- Home Depot, Lowes, Michael's craft stores, waterfall and water feature stores, Target, WalMart and sometimes Big Lots. I've also found supplies to build decorative water pumps at my local nurseries, Green Thumb and Armstrong.

- Q: Every year my family spends a week on a house boat at Lake Powell where it can get extremely hot in the day time. I'd like to build a mist system using pvc pipes and mist spray heads to help cool us down.I'm not sure what kind of water pump to buy? I've looked at different kinds from submersible to non-submersible, all with different amounts of PSI and GPM. I am not familiar with water pumps and could use some community insight.I want to make sure the pump I get does not burn out because of the back pressure it will get due to the mist heads only allowing a little water to escape at a time.I imagine my mist system would have 8 - 12 heads, reaching no more then 30 feet from water source to the end.Any pointers? Thanks!

- I am assuming your water source will be the lake …. I would be looking at a submersible pump possibly a pond pump but you need to know what the “lift” is going to be …from the point where you string the mister to the pump {possibly a 15 foot lift} and a pump that will give you at least 25psi. Because you are going to have back pressure, the submersible will reduce the risk of burn out. Also you need to build a simple enclosed container this pump can sit in, with at least a 4”water inlet hole covered with mosquito netting, nylon hosiery, or something to filter the water….otherwise you will constantly be removing the mister heads to clean

- Q: My pump is almost 4 years old, work normal till recently I noticed sand mixed water flowing out of the delivery pipe. What should I do to make it normal again?

- If it is pumping sand there is a problem of course. The pump is generally hung about 10 feet from the bottom of the well ( Ex: if the well is 120 feet the pump would hung be at 110 feet). In your case it may have been closer to the bottom and picking up the sand. There is a possibility that recently another well has been dug in the area and disturbed sediment has gotten in the water. It sounds like you aren't using this as drinking water or the sand would have been dropped in the pressure tank and you wouldn't see it. If it is a seasonal use well ( like for your garden or lawn in spring through fall) this debris might wash out after a few uses.

- Q: Which is the better option for a home water pump? a submersible pump or floor based pump?

- last week i got a price on a above ground pump it pumps water up from 100 ft. it sure beats pulling 100ft of caseing every few years

- Q: I will be replacing my timing belt soon. The dealer is suggesting that I also replace the water pump. Is that really necessary? When do water pumps normally go out?

- Water pumps have bearings, some new cars use plastic impellers. Eventually these do wear out. As you paid all the labor to get at the water pump, might as well replace it with a new one.

Send your message to us

Agricultural Irrigation Double Suction water pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords