Geomembrane Pool

Geomembrane Pool Related Searches

Geomembrane Pond Geomembrane Machine Plastic Geomembrane Geomembrane Landfill Geomembrane Roll Geomembrane Factory Geomembrane Tanks Tpo Geomembrane Geomembrane For Ponds Geomembrane Welder Geomembrane Containment Geomembranes Pe Geomembrane Geocomposite Membrane Geomembrane Properties Geomembrane Material Geomembrane Pond Liner Gse Geomembrane Geomembrane Products Geomembrane Drainage Geomembrane Systems Geomembrane Technologies Landfill Geomembrane Composite Geomembrane Permeable Geomembrane Rpe Geomembrane Geomembrane Fish Tanks Geomembrane Anchor Waterproof Geomembrane Geomembrane CoverGeomembrane Pool Supplier & Manufacturer from China

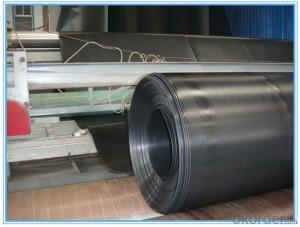

Geomembrane pools are a type of water containment structure made from flexible, impermeable materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). These pools are designed to hold water in various applications, including recreational swimming, water storage, and aquatic farming. They are known for their durability, low maintenance, and cost-effectiveness compared to traditional concrete or fiberglass pools.Geomembrane pools are widely used in various settings, from residential backyards to commercial water parks and agricultural facilities. They are particularly popular in areas where water conservation and efficient use of space are important, as they can be easily installed and adapted to different terrains and environments. These pools can also be used for temporary or seasonal purposes, such as during droughts or for special events, making them a versatile solution for water management.

Okorder.com is a leading wholesale supplier of geomembrane pools, offering a vast inventory of high-quality products to meet the diverse needs of customers worldwide. With a commitment to providing excellent service and support, Okorder.com ensures that customers receive the best geomembrane pool solutions for their specific requirements.

Hot Products