Wellhead Assembly of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Wellhead Assembly Description

The gas production wellhead assembly is designed and manufactured in accordance with GB/T22513-2008 and API Spec 6A standards.All pressure-bearing parts and flanges are forge pieces of high-grade alloy steel and stainless steel and subjected to non-destructive test(NDT) and special heat treatment to insure safety and good sulphur-resisting performance.

This product consists of such components or parts as bottom flange,top flange,tubing head,gate valves,small-sized four-way union,stop valves and measuring instruments,etc.

2. Main Features of Wellhead Assembly

Working Pressure: 2000-20000psi

Working Temperature: PU Material Class: AA-FF

Available Medium: Crude Oil, Water, Gas

Connection Type: Clamp, Flanged

PR: PR1-2

PSL: PSL1-3

Normal Size: Main (in): 2-9/16, 3-1/8, 3-1/16

Side (in): 2-9/16

3. Wellhead Assembly Images

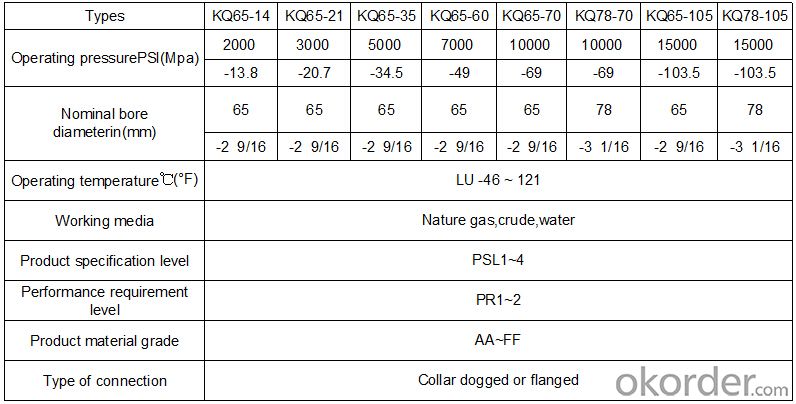

4. Wellhead Assembly Specification

5. FAQ of Wellhead Assembly

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I was told Wed. that I need to have my aortic valve replaced. I was wondering if anyone could share their experience with this surgery good or bad. I am meeting with the surgeon on the 26th, and am very nervous. Any tips and or suggestions appreciated. I'm a 39 year old female.Thanks in advance

- Lisa Sorry to hear that you have to have this done . I will put you in my prayer's , Haven't heard from you in some time if you feel like chatting send me a e-mail . Hope all goes well and Merry Christmas

- Q: what are the best aorta heart valves. mech. or animal.

- The ones you were born with.

- Q: Can you please explain to me what an atrial valve is and what it does??

- By atrial valve, I assume it meant the atrioventricular valves. Basically, in the heart, the blood flows from right atrium, right ventricle, left atrium, left ventricle. The atrioventricular valves are the tricuspid and bicuspid valves. They make sure the blood flows from the right atrium - right ventricle and left atrium - left ventricle respectively and prevents blood from flowing the wrong way in those chambers.

- Q: people tell me i need to install new valves and valve guides

- You might not need new valves or valve guides. Mitsubishis, along with many other vehicles, use hydraulic lifters which give off a ticking sound. They're located between the rocker arm, or in the rocker arm, and the head of the valve. It's very common and will not harm the engine. However, if the sound you're hearing is more of a rattling, like putting some nuts and bolts in a glass jar, you may need to pull the valve cover off and inspect for yourself to make sure that the rocker arms do not have any play to them while they are pushing on the valves. If there is any play in the rocker side to side, you may need to replace those rockers. However, if there is any play up and down you may just need to replace the lifter. To better check if you need new valves or valve guides run through this checklist: Are you burning oil? Have you done a compression test (both wet and dry)? And if so, were the compression numbers within spec? Have you felt a loss in power/idle quality/gas mileage? Is your oil level correct/using the correct oil/non-FRAM oil filter? At your next oil change, instead of using the recommended 5W-30 engine oil, try switching to something a little heavier, such as 10W-30, to cancel out the effect of possible lifter tick. Do not use a FRAM oil filter if you have in the past since they're filters tend to have additives that are unnecessary and may cause the engine harm.

- Q: i have a 1986 Ford Mustang 3.8L V6 automatic. i need to change to valve cover gaskets but im not sure if i can do it. what do i need to do? and do i need to ad something else other than new gaskets? thanks

- Valve cover gaskets are very easy to change. Just make sure you get good gaskets, and when you tighten the bolts back down make sure you alternate bolts back and forth, don't torque one down and then jump right to the next one or you'll warp the valve cover since its aluminum. Start with one bolt get it slightly snug, then go to the one in the opposite corner and do the same, keep doing that until you have them all slightly snug, then start slowly torquing them down until they're all set at the proper torque. (Sorry I don't know the torque on those bolts).

- Q: i have got a problem with the valve but i have some guy gonna try and clean it next week. i have heard of blanking plates. has anyone used one of these? do they make any difference in the way the car goes ?

- Think okorder . Go on line an read: Function EGR Valve before you ruin the engine with a block-off plate.

- Q: im 16 and im rly scared i have already been checked out by the hospital and they sed that i have a moderately leaky heart valve. They recommended me to see a childrens cardiologist since they dont specialize in children. i have to get another echo and some other tests done i think. im so nervous. whats going to happen to me??

- dont mind buddah ,youl be fine 1 in 5 people have it and never know but you can live a worry free full life just like anyone else as long as you look after yourself

- Q: I have an above ground water pump. there is good pressure(40), but the pump does not stop. Pump co did diagnostic test and said that foot valve needs to be replaced. The company charge me $399 for diagnostic test and and about $2200 for the foot valve replacement. It is reasonable.

- WOW! Just read my exact problem there...I do have a water feed and pressure build up to 40 psi BUT same here...Pump will not stop. About 8 years ago I myself with the help of some friends pulled the two pipes from the well bottom put all new fittings on. Replaced the pressure tank and installed brand new well pump. So from what I am reading here I am understanding it is the foot valve that is causing my problem now. So I feel I can pull the two lines (55') and replace the foot valve and hopefully this is my problem??? I noticed as long as the pump is left running it builds up 40 psi and we can run our water but at 50it is suppose to shut the pump down but will not...OK?

- Q: I need to make a ball valve that will open with no manual force but by a motor of some sort to spin it and release water. how do i make a ball valve controlled by preferably a motor or other CHEAP device. I need to do this for less that 20$

- put a slave servo on it,

- Q: i have this valve and its really stiff i was wondering if there's a way to loosen it up a little its a KBI Ball Valve baught at Ace hardware and it looks like their might be a way of adjusting it i just dont know how

- tap it lightly with a hammer while turning it

Send your message to us

Wellhead Assembly of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords