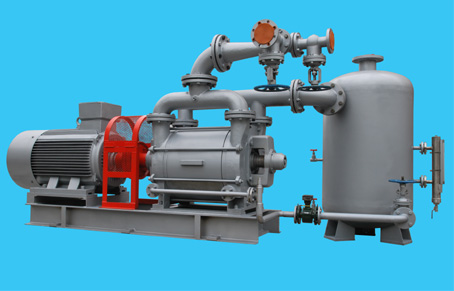

Waste Water Treatment Centrifugal Pump System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waste Water Treatment Centrifugal Pump System

1. Product Introduction

Complies to API610, 682,ISO2858standards

Max pressure: 2.5MPa

Capacity: 0.64~2400 m3/h

Head: 4~250m

Capacity : 0.64-2400m3/h

T: -20---200oC

2. Material

Material (For wet parts in contactwith medium): CS, cast iron, 304(0Cr18Ni99ti), 305 (1cr18ni9t), MCU, CD4MCu,316, 316L, 310S, alloy 20#, 904, ta2, Ti/pd (titanium-palladium alloy), Ni(nickel), Monel. Dual-phase stainless steel, etc.

3. Mechanical seal

According tocustomer's requirements

We provide:

1. Mechanical seal---171(A) mechanicalseal (this kind of seal is the national-patented product, patent No. ZL92 220977.4 ) single or dual MS.

2. Dynamic seal.

3. Packing gland seal.

Or other brands.

Coupling: Pin type coupling

4. Application

Soda, paper, salts. Metallurgy,acid-making, petrochemical, fiber, plastic, paper-making, chemical fertilizer.Fermentation, environmental protection.

5. FAQ

1 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

2 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

3 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: What is called soft start of water pump?

- Soft start has many methods, mainly used in high-power motor.Through soft starter, or frequency conversion start, or star triangle start to achieve.It means that it starts at a slower pace.

- Q: How do I know the pump pressure?

- The "H=100M" in the parameter is the pressure index of the pump. "H" is the height of the head and the height of 100m. Since the 10M lift is approximately equal to 1Kg/cm2 pressure. Your pump is 10Kg/cm2 pressure.Q=18 M3/H, that is, 18 cubic meters of traffic per hour;H=100M, that is, rated head 100M, high head;P=4.0 KW, that is, the motor power is 4 kw.

- Q: We bought a second hand Rover 75, three months later head gasket blew. This was replaced but blew again due to original wet liners. A reconditioned engine was then put in but head gasket blew again due to original water pump. I am not trying to ascertain blame i would just like to know which is accurate as car seller is saying fault of mechanic as should have changed wet liners and water pump and mechanic is saying it is not common practice to change this parts when you replace a head gasket or engine. Thanks for any clarification, especially if you are a mechanic yourself.

- It seems excessive to have to remove the engine to replace a head gasket. But I typically work on American cars, and I've seen the inside of an Altima, it is quite cramped. If I were you, I'd search google for replace head gasket procedure nissan altima and see what it comes back with.

- Q: I just move to this house, it's been empty for a while. The water pump keep screeching everytime I turn it on. What can I do to get rid this noise?

- Is there water in the system? Pump bearing worn Find a bleed point on the pump and vent any air from it with the pump Off.

- Q: The water pump in my trecel is damaged and i need to take it to a shop that's about 20 minutes away from my house will turning on the heater and adding coolant help me to get the car there without damaging the engine

- If you have electric fans to cool the radiator down you can turn on the airconditioning or the defrost which will make the fans run continuously keeping the water cooler for a longer period of time

- Q: I have a deep tropical fish tank, my three in one pump is 15 watts, if I put it in the middle of the active oxygen bubbling tank can function, everything is normal, but not very good filtering, can not clean up the garbage at the bottom of the tank. So they put the pump a little deeper, but at this time the pump does not bubble, the oxygen supply in the pipe there is water, atmospheric pressure can not enter, but still can pump water filter, so that the pump itself harmful? Will the pump burn out? This question is very important to me. Please help my brothers and sisters downstairs. I will thank you for my dear tropical fish

- The easiest way is to pump a bottle of mineral water under the pump. It's too long to cut off some of it.Bottle to the end, the pump can beat oxygen on the line. A hole is under the bottle.

- Q: I have a Honda Accord, and last week I replaced the Radiotor, due to a leak. This week the Water pump broke, it was making a ver loud noise and major leak, when I opened the rad, basically all the fluid was drained.Do you think the two are related? or do you think when the Rad was replaced it was not done properly which caused the water pump to break?Thanks.

- Yes they are related. First why did you replace the radiator if their was a hole in it it could have drained out most of the fluid and burned up the pump.

- Q: Water pump 50HZ impeller and 60HZ what is different, why not the same?

- Water pump 50HZ impeller and 60HZ impeller, its outer diameter is not the same, 60HZ impeller slightly smaller. Because the speed of the impeller of 60HZ is faster, the impeller is a little smaller.Flow rate and speed, impeller diameter into a relationship: Q1/Q2 = n1/n2=D1/D2;Head and speed into two relations: H1/H2 = (n1/n2) 2Motor shaft power and speed into three relations: P1/P2 = (n1/n2) 3From the above deduction, we can know that the motor speed formula is n=60f/p, in which n is motor synchronous speed, and F is supply frequency. P is the pole number of the motor. It is known that the power supply frequency of the motor is proportional to the speed of the f. Therefore, to obtain the same head or flow, high speed, to use a smaller impeller.

- Q: Is this a symptom of a bigger problem or do I just need to replace the water pump?

- Most definantly water pump gasket or seal. If leaking out of front seal (we call it the tell tale), replace w/pump. If its a gasket, its your call - either gasket or entire pump (depends on age of vehicle). Either way - good luck Cheers

- Q: I have septic tanks. My toilet flushing water is filthy and the water pump runs for a long time and sounds strange. I have turned the pump off for now but know this is not an answer but i was worried it would burn out or something. Do i need a part for the pressure pump? Please help any plumbers out there.

- When you go to the hardware or home improvement store, whichever you have around your area, ask for a CLOSET AUGER. No home should be without one. Once you use it you'll wonder why you ever bothered with a plunger. This thing is made specifically for toilets and is simple to use and unclogs anything within and slightly below the floor line. Any clerk at either a hardware store or the home improvement stores should be able to show you how to use it and it costs about $10.

Send your message to us

Waste Water Treatment Centrifugal Pump System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords