Vacuum Pump Suction Sewage With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

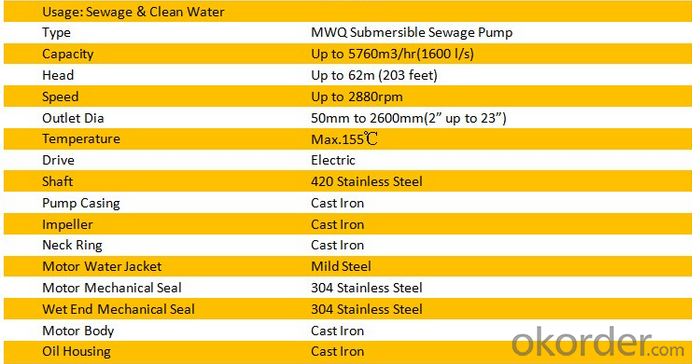

Specification

Vacuum Pump Suction Sewage With High Quality

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

My company has organized product research and development team, experienced high, intermediate technical staff.

Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.

Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

My company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.

Relevant product standards (enterprise), metrology, standardization management system, etc.,

have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and aftersales service, are performed according to the system management standard.

Application

This series pump is widely used for sewage treatment of city construction discharge for architecture projects, hotel, mine, pond, dyeing and printing, paper making and textile industries.

It is the ideal tool for transportation of sludge, slurry, living sewage, feces and stale wastes, solid grains fiber, paper chips, sandy soil etc.

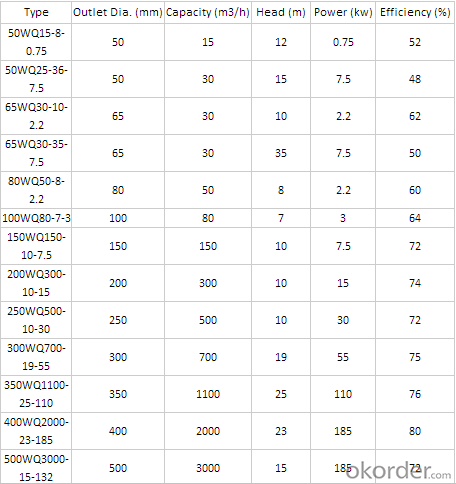

Model Description

100 WQ 50-30-3

100: Drain aperture (mm)

WQ: Submersible sewage pump

50: Capacity (m3/hr)

30: Head (m)

3: Power (kW)

Operations Conditions

1. The medium temperature should not be over 60oC, the density 1200Kg/m3, and the pH value within 5-9.

2. During running, the pump must not be lower than the permitted lowest liquid level.

3. Rated voltage 380 V, rated frequency 50 Hz. The motor can run successfully, only under the condition the deviations of both rated voltage and frequency are not over ± 5%.

4. The maximum diameter of the solid grain going through the pump has not to be larger than 50% of that of the pump outlet.

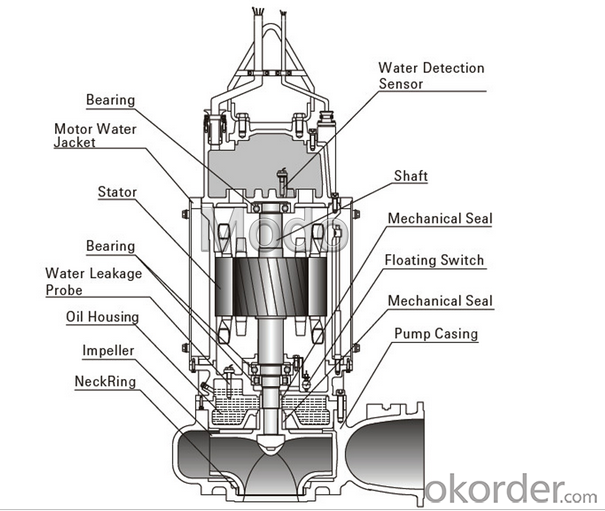

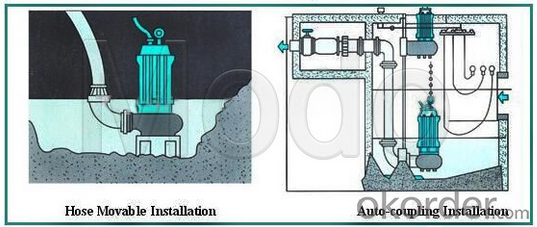

Pictures Show

Trading market

Transportation

- Q: Does the water pump pump the coolant into the engine or pump it out?

- Strictly speaking, the pump is powered cooling fluid circulation, which is pumped into and out of the water pump is to rely on to complete the engine, the water tank and the pipelines are connected to form a closed loop, the engine cooling water tank, heat release, heat exchange by circulating cooling liquid, and let the power coolant flow up from the water, like the human heart as the power of the arteries and veins are provided by the contraction and relaxation of the heart of the.

- Q: can stress from to much weight cause the engine to get hot and cause your water pump to leak out the weep hole? and what else causes it to leak?

- WELL THERES ALOTE OF THINGS BUT THE MOST LIKELY IS MILES ALOTE OF MILES THEN THEY WILL FALL APART I FOUND BEING I WORK ON CARS THAT ABOUT EVERY 50,000 MILES CHANGE THE WATER PUMP AND YOU HAVE NO PROBLEMS

- Q: First the shop put in a heater core, but it was still leaking and overheating. Next they put in a water pump. Went to get it and now it wines really loud and the engine use to purr like a kitten, couldn't even tell it was running, now the engine shakes the whole car and it died one the way home but started again. The shop said the cam positioning needs reset again and on the way back to the shop it died again. So from leaking anti-freeze to now it vibrates, dies and wines really loud ! Any ideas what they did wrong ?

- Matbe they forgot to replace water pump gasket, timing belt not aligned with timing of engine.

- Q: what is a submersible well pump?

- lets break it down... submersible- able to be put underwater... well- deep hole that water comes from... pump- sucks the water...

- Q: I need to replace a water pump on a '95 3100 Pontiac Grand Am and am looking for a guide how to do it. Also, do I need to flush out the coolant or can I just put a pan underneath the water pump and let the coolant pour out when I take the water pump off? Thanks.

- some autos have diverse designs. The water pump on my 96 Century would were finished in a be counted of minutes. the position as some are a lot deeper in the engine. frequently, to modify a water pump like it is extremely somewhat an additional desirable step than replacing the timing belt. it is the reason it is continuously a good idea to do them both right now.

- Q: I'm going on a week long hiking trip and need safe water. What brand and model of water filter/pump should i get? Whats good quality for a low price?

- The okorder /

- Q: This is a brand new water pump and we used plenty of gasket maker. Does this year of f150 need the back plate that comes on the water pump?

- if its leaking from the weep hole then u have a bad pump.....return it and get another.... if its leaking from a seal or from the silicone ....u will need to remove it and reinstall it......this time make sure silicone is evenly spread ......

- Q: Okay, the fan has the clutch unit on the front with the large nut attaching it to the water pump. Then 4 screws attach the pulley to the water pump as well. What's the best way to immobilize pulley/pump so I can get the fan blade clutch nut unscrewed? Can't hold onto the fan or clutch unit since it simply spins. Can't realy seem to hold onto the pulley either as it prefers to spin? Any suggested best ways?

- First remember this tighten is loosen and loosen it tighten with the big nut on the fan clutch. And there is a tool you can buy (BMP design and Bavarian autosport have them) but I never bought one because I only could have used it once, and I try to keep my tool box as empty as I can. All this with the belt on..Get the biggest screwdriver you have and a heavy hammer. Now put the screwdriver on the tighten side one of the flat sides edge. Take hammer and give it a big wack. As long as the last guy put the fan clutch on right it should take no more than 2 tries to loosen it. Once its loose just spin it off by the fan blades and pull it out. I only once had to use a sawsall (only time I could have used the tool)on both the water pump and fan clutch to do a water pump job and after inspection I found some moron used lock tight. When you reinstall just spin it on and that's it no need to tighten.. I like to put antiseize on the bolt threads so I know the next time I have to remove the fan it will come off like buttahr...

- Q: Water is leaking from the front of my car, on the right where the radiator is located. only thing is that its not leaking a lot, just a little.... but people keep telling me that my timing belt is going to go out and that i will be stranded!. i will like to know the cost of both the water pump and timing belts for my 2001 PT Cruiser please.

- replace water pump timing belt pt cruiser

- Q: i need to change my water pump on my vw 1990 gti. the more details and/or pictures the better or links i can go to to show me

- The 1990 4 cylinder was before they ran the pump off the timing belt, so it is still V-belt driven, and it is not necessary to touch the timing belt. Since it is belt driven, you should expect it to be near the passenger side of the engine, but it actually bolts to the front of the engine, near the bottom. In the linked image, they have included the housing, which you see bolts to the side of the block with an O ring seal. It is recommended you remove this housing, so that you can more easily get at all the small bolts holding the water pump to the housing. But there is no reason not to reuse the old housing. This also has the thermostat in it, so replace that at the same time. You may be able to leave the hoses attached if you are working on a lift, from below. The power steering pump may be in the way and need to be lowered. Take the passenger side wheel off. If you have to get at it from the top, it may be much harder, because the AC mounting plate would need to be removed and the head gets in the way, but also possible. Set aside a whole day, just to make sure you have enough time to finish if this is your first one. But you could probably do it a second time in about 3 hours.

Send your message to us

Vacuum Pump Suction Sewage With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords