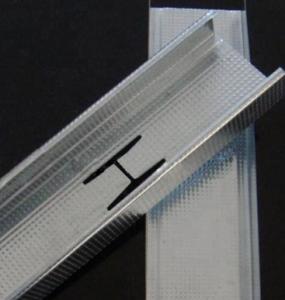

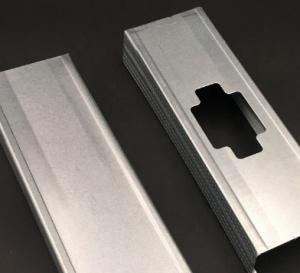

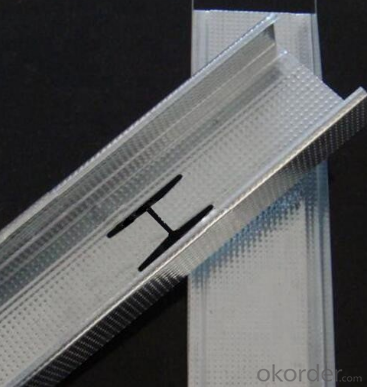

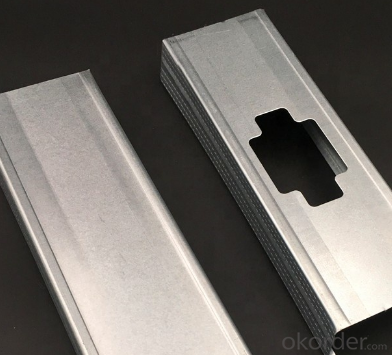

Ceiling Profile for Drywall Partition and Ceiling

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

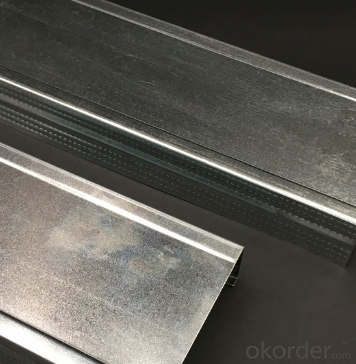

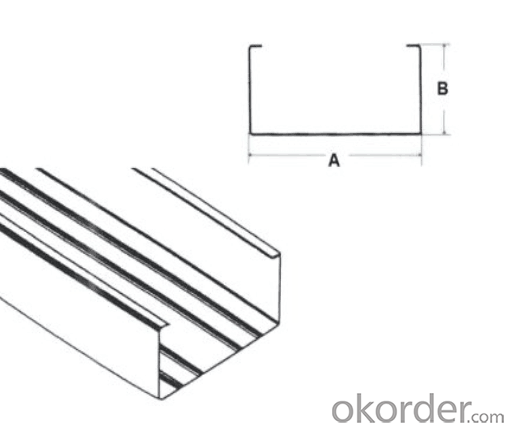

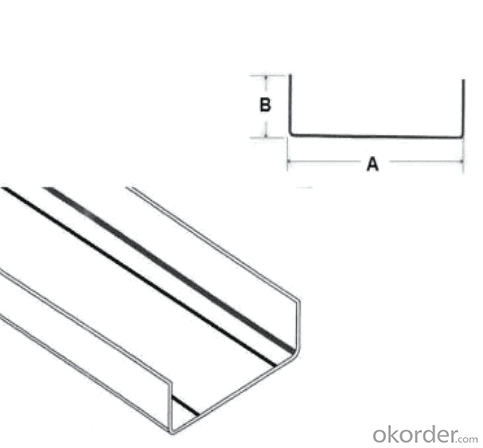

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q:Construction schedule of light steel keel ceiling

- 2 people, about 3 days. Good workers are faster

- Q:Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel thickness has nothing to do with the height of the ceiling, and the span of the relationship between the ceiling, span, light steel keel thickness is slightly thicker.

- Q:Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q:Light steel keel ceiling which brand is better

- You can go to the forum to consult the other owners to see everyone's views

- Q:Light steel keel gypsum board ceiling technology

- This is based on the price, the shape of the more complex ceiling, depending on the specific circumstances to determine.

- Q:What is the keel of the aluminum veneer, or the angle welded frame?

- Now are the use of light steel keel. Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on. Light steel keel according to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-shaped, U-keel. Light steel keel mark the order of the order: product name, code, cross-sectional shape of the width, height, plate thickness and standard number. Such as the cross-section shape of "C" type, width of 50mm, height of 15mm, steel plate thickness of 1.5mm ceiling keel marked as: construction with light steel keel.

- Q:What kind of thickness of the light steel keel there is no specification?

- I think the real construction of the main situation is to see the cost requirements, under normal circumstances with 0.7-0.8 centimeters on the

- Q:Gypsum board ceiling side keel with a good side of the wood or supporting the light keel edge keel good?

- Of course, is the use of supporting the light steel keel (edge keel) better, and the construction (operation) will be more convenient.

- Q:Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Light steel keel can be down from the roof down 1-2 meters, for the air conditioning, fire, communication, weak left there are maintenance mouth ,,, people can stand on the light steel keel repair equipment (at this time, the main keel must be 60 main dragon 60 * 27 * 1.2MM), This is the wood keel will never be able to do Before ,,, home decoration because the construction is relatively small ,,, hanging under the back and very small, so the carpenter with the wooden side . But the improvement of living standards ,,,, the use of light steel keel is a big trend ,,,,, in foreign countries are doing so Domestic, many of the current decoration company, also used the light steel keel ,,, I know that OKorder is the East Yi Sheng, ,, Long hair ,,,,, 3> light steel keel can make a variety of modeling roof, wood keel can not do ,,, is done, the effect is very bad ,,, 4> light steel keel construction fast ,,, good maintenance ,,,,

- Q:Light steel keel how to do secondary ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling. Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Profile for Drywall Partition and Ceiling

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords