PVC Ceiling and Panels are Fireproof Heat Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

PVC Ceilings are ultra modern and are popular all over the world. PVC Ceilings are an ideal substitute for the ordinary gypsum board ceilings.

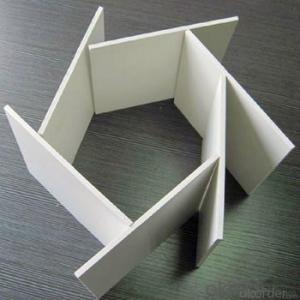

The interlocking PVC panel achieves a smooth texture which is lacking in other ceiling materials where splicing gaps can be seen between the plates.

The hollow structure of the PVC panels contributes significantly to the insulation effect that guarantees a cool summer retreat and a warm room in winter, ideal for the South African climate. PVC ceilings are lightweight and therefore easy to install with less labour.

Product Advantages:

This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling. PVC Ceilings are very versatile and can be applied in just about any indoor environment

Type:Ceiling Tiles

Place of Origin:China

Function:Fireproof, Heat Insulation, Moisture-...

Feature:Integrated Ceilings

Ceiling Tile Shape:Rectangle

Ceiling Tile Type:PVC Ceilings

Function:Fireproof,Heat insulation,Moisture-Pr...

Main Product Features:

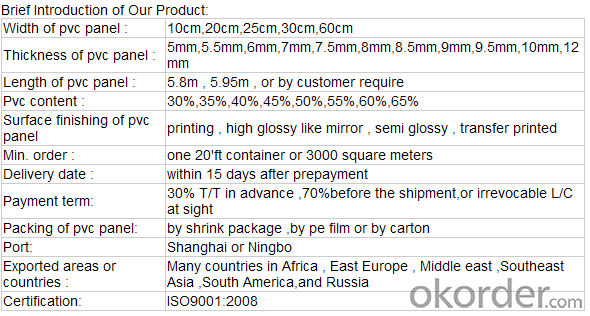

Thickness: 5mm, 7mm, 7.5mm, 8mm, 9mm or by request

Width: 10cm, 18cm, 20cm, 22cm, 24cm, 25cm, 38cm or by request

Length: Regular 5.95m, also as per your requirements.

pvc ceiling panels Features: Fireproof, waterproof, anti-warm and environment friendly,

For Ceiling and Wall decoration

Product Specifications:

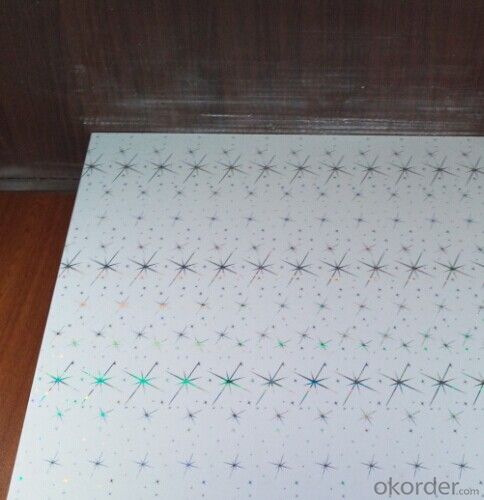

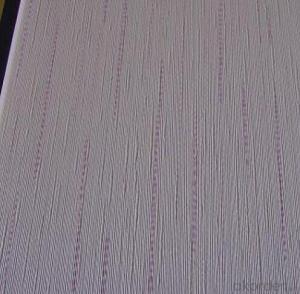

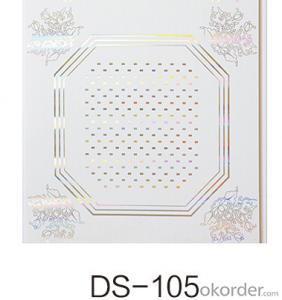

Images:

- Q: I have a blank PVC gusset plate, plastic material. I want to buy some heat transfer film transfer up, but do not know what equipment through the heat, the general plane thermal transfer machine can it? I am worried that the plastic buckle into the thermal transfer equipment will heat deformation. Please recommend a transfer on the plastic equipment, thank you! Do you buy some blank thermal transfer film through the printer can be printed after the thermal transfer to plastic up?

- Now many do not use the heat transfer, and that too much trouble, you can directly use uv digital printing presses. That is dry, the effect is very good. Small 6090 universal printer, printing format 60cm * 90cm, double DX5 nozzle, priced at 5.5w. Printing speed of 2-6 square meters / hour. Printing field with mobile phone shell, leather, handicrafts, high-precision business equipment.

- Q: The kind of ceiling of the striped groove (pvc?) Board wall how

- The market to see, with that kind of wall is only possible, but the middle must be joined woodworking board or wood keel, and both sides are nailed to this board, the price is not cheap, but save the brush wall part

- Q: Home wall rain easy to seepage, the decoration of the wall can be what moisture-proof material? Heard that PVC board is good, can be used for the wall?

- With aluminum plate, more expensive,

- Q: Ordinary PVC board can be posted wallpaper? Or paint is mainly to improve its appearance

- Paint for the PVC, but this has been decorated with a board of non-professional paint will not flat, do not look blanket! Willing to spend money, you can find manpower painting chanting

- Q: How to deal with matte PVC mat noodles

- Late hot or sandblasting or chemical corrosion bar. Anyway, there are so few surface treatment

- Q: Pvc board can not be posted on the wallpaper, can be used to how long

- According to the actual situation

- Q: Who knows, acrylic board, organic board, color plate, PVC board What is the difference.

- I suggest you refer to the relevant plastic network or footwear network. These can be consulted. Detailed description, time consuming too much!

- Q: Will pvc floor is how to make out, it is best to specific? Thank you!

- More is the wood-plastic foam board is nothing more than resin powder, wood powder, hard calcium, stabilizer and other small material mixed extrusion

- Q: Aluminum buckle plate and PVC gusset which is better

- One is to see what you want to hang in the location, and second, how much money you want to spend to decorate, in general, not only elegant appearance of aluminum plate, practicality is also very strong, waterproof anti-aging and other aspects than PVC button board, But also suitable for the installation of Yuba lights and exhaust fan, but the price will be expensive than the PVC buckle board, PVC gusset plate is also a commonly used ceiling material, the general thickness of the older life longer, but still can not be compared with the aluminum plate

Send your message to us

PVC Ceiling and Panels are Fireproof Heat Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords