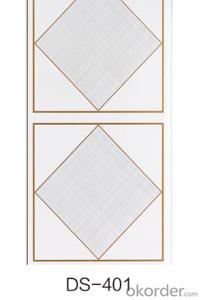

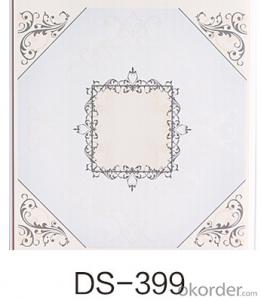

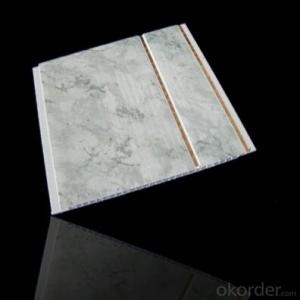

PVC Ceiling Wooden Panel 200mm - Best Selling in Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Printing PVC Ceiling 200mm 40% PVC Best Sell In Africa

1.Easy to install and clean

2.Best cost performance

3.colorful

Main material | pvc resin,calcium carbonate | |

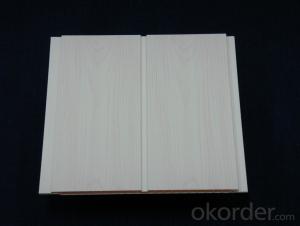

Specification | Width | 100/180/200/250/300/595/600mm |

Thickness | 5/5.5/6/7/7.5/8/8.5/9/10mm | |

Length | 5800mm/20GP 5950mm/40HQ | |

Weight | 1.6-4kg/sqm | |

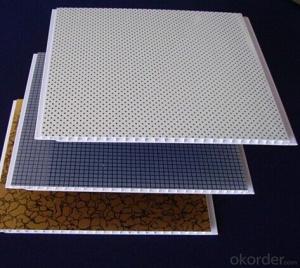

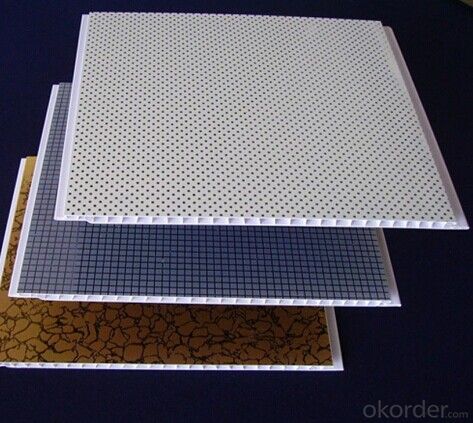

Surface Finishing | Common Printing | Flat groove |

Transfer printing | Flat groove | |

Laminated | Flat groove | |

High glossy | Flat groove | |

Glossy | Flat groove | |

Ceritificate | ISO9001,2000 | |

MOQ | 20GP | |

Payment | 30%TT in advance,70% before the shipment | |

PVC percent | 40% 45% 50%,55% 60% | |

The feature of PVC Ceiling Panel:

1) Easily assembly and clean

2) Without gap when concatenated

3) High intensity, corrode-resisting, aging-resisting

4) Due to PVC's high chemical stability,our panels can be used more than 10 years

5) Prevent fire,water,antibiotic.

6) Harmless to human being and eco-friendly

7) For Ceiling and Wall decoration

8) Accessories(corners) accompany perfectly

9) Serial number of different specification

Types of PVC Ceiling Panel we are producing:

1)Glossy PVC Panel (most common type)

2)Sub-glossy PVC Panel (Natural surface handing)

3) High-glossy PVC Panel (high-light surface handling)

4)Transfer Printing PVC Panel

5) Laminated

Application of PVC Ceiling Panel:

1)Household Ornament: Wall and ceiling of indent independent house bathroom

2)Public and Management Place: Toilet of building and hall

3)Common Office: Ceiling of business Place

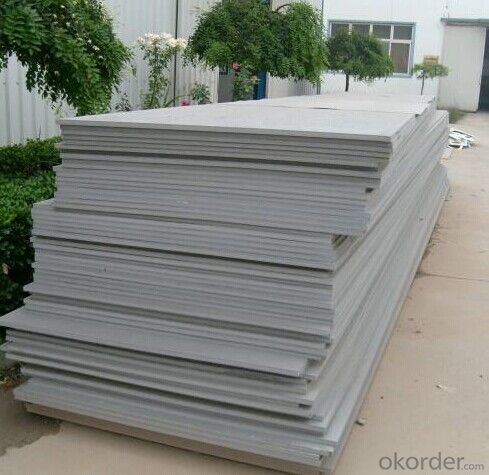

Packing&shipping:

Bales of shrink:10 pcs per bale or customized design 2.carton:10 pcs per carton or customized design PLS Note :Both of these two kinds of packaging can be with customers' own trade marks and brand names.We do strongly recommend our customers to choose bales of shrink for packaging,because by doing this,you can load more for a container and pay less(cartons cost more).10pcs per package,545 packages per 40HQ (8106sqm)

- Q: Pvc board in the outdoor high temperature with what glue is good

- Pvc board in the outdoor high temperature can be used HY-108AB glue bonding, the highest resistance to 200 degrees.

- Q: Are PVC environmentally friendly?

- I see a lot of online marked "green PVC" words of the product, but the search and found that PVC and this kind of thing is almost plastic, in fact, not environmentally friendly. I am very confused, that is, environmental protection is not environmentally friendly ah? Now how much of the PVC products on the market are really environmentally friendly?

- Q: Pvc plastic acid corrosion

- PVC resistant to most inorganic acids (except fuming sulfuric acid and concentrated nitric acid), alkali, most organic solvents (such as ethanol, gasoline and mineral oil, etc.) and inorganic salts, suitable for chemical anti-corrosion materials.

- Q: Pvc floor with what glue

- Pvc floor special glue: Wan Jun (WJ) card features: Solvent-free, green products, in line with the EU ROHS standards Excellent initial tack and final tack strength Construction convenience, the amount of economic, high coating rate Longer opening time, bonding lasting strong Suitable for geothermal system grassroots

- Q: Colored PVC board is what kind of board ah, can not paint

- There are many types of colored PVC board. 1, advertising with the PVC plastic plate; 2, PVC surface paint board; this PVC board is no need to paint, because their material color and texture there are many, the paint is not necessary. And this PVC board surface will generally glazed, paint up the durability will not be durable, will be from the skin, rupture and so on.

- Q: Has anyone tried this? I need to use it for a window that is 8'4 wide and due to the construction of the ceiling (concrete) and window frame (metal) I can't put in any center support. What diameter pipe did you use and what is the width of the window you used it on? Any tips/tricks?

- If okorder / You can fasten the brackets to the concrete ceiling with Tap-Con masonry screws, which you can find at home improvement stores. You will need to predrill with a masonry bit, which is sometimes included with the packages of screws. Otherwise, you can also get it at the store in the same section. If you want to go with a metal rod and use less support brackets, the link above has long rods that you can connect together very easily. A 1 1/2 rod would be best for that span and you can get 2 rings if you need them.

- Q: If you use PVC board to be a simple cylinder, then there is a piece of mouth that piece, how can we avoid it?

- Welding with PVC electrode can be

- Q: What is the difference between pvc flooring and plastic flooring? Is there a stone floor?

- Of course there is a difference! Stone floor is a sheet, plastic floor is a coil, OKorder and OKorder plastic flooring factory has a coil dance plastic floor dance dedicated! Sports plastic floor badminton court dedicated, table tennis field dedicated, gym dedicated, basketball court dedicated! OKorder plastic floor PVC flooring is a very popular in the world of a new type of lightweight ground decoration materials, the advantages of many, also known as "light body material." Is a popular in Japan and the United States and Japan, Japan and South Korea popular products, popular in foreign countries, from the early 80s began to enter the Chinese market in the country's large and medium-sized cities have been widely recognized, the use of a very wide range, such as indoor families, hospitals, Schools, office buildings, factories, public places, supermarkets, commercial, sports venues and other places. "PVC floor" refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production.

- Q: PVC sheet with formaldehyde?

- More or less will be some formaldehyde, the plate made of furniture can be used liquid Maya blue is the main component of the extraction of hydroxypropylated derivatives in plants, through complexation, condensation, addition reaction, rapid capture of benzene, ammonia Compounds, mercapto compounds, formaldehyde, TVOC and other volatile compounds with odor. Sprayed on the surface of the furniture, the formation of a layer of colorless, tasteless, transparent film, it can have α-hydrogen atoms and aldehydes, weak base or weak acid under the effect of condensation from β-hydroxy aldehydes or ketones Further polymerized into macromolecules nonvolatile compounds, no longer volatile into the air, so as to achieve the principle of removal of harmful substances.

- Q: Pvc board and pp board that is a lot of color, the kind of more suitable for kitchen and toilet waterproof furniture, furniture for the density of the board, specifications and other parameters are generally how much, about how much the price, China Province and the surrounding area Where can I buy this type of plate, the phone number is how much (I need is 1.5cm, 1.6cm and a small part of 1cm and 2cm of the plate)

- PP board: polypropylene (PP) plate, (PP pure plate, modified PP board, enhanced PP board, PP electrode) pure PP board: small density, easy welding and processing, with excellent resistance, heat resistance and Impact resistance, non-toxic, tasteless is the most environmentally friendly one of the engineering plastics. The main colors are white, microcomputer color, other colors can also be customized according to customer requirements. Applications: Acid and alkali equipment, environmental protection equipment, waste water, waste exhaust equipment, scrubbers, clean rooms, semiconductor plants and related industrial equipment, but also the preferred material for the manufacture of plastic water tanks, PP thick plate widely used for stamping Plate, punch and so on. Pvc board: polyvinyl chloride (PVC) plastic is a vinyl chloride monomer by free radical polymerization of the polymer, the English name polyviny chloride, referred to as PVC. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

Send your message to us

PVC Ceiling Wooden Panel 200mm - Best Selling in Africa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords