High-Quality W Angle Ceiling Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

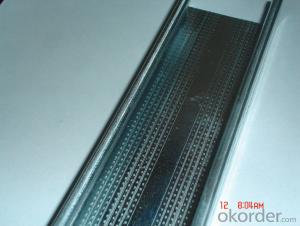

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

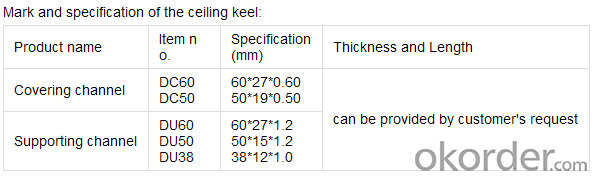

Product Specifications:

Images:

- Q: Light steel keel gypsum board modeling ceiling

- Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel.

- Q: Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- With the card can be the main bone there is 40 cm in the wall is like to consider the installation of the space

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- Light steel keel is above the keel, the ceiling should use keel, gypsum board ceiling also use keel, generally with wood keel, of course, can also use light steel keel friends, to say that the price is light steel keel expensive.

- Q: What kind of size of the ceiling?

- 30 * 40

- Q: I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- No, gypsum board is too brittle easy to rotten

- Q: Light steel keel gypsum board ceiling construction practices?

- Product protection 1, light steel skeleton, cover panels and other ceiling materials stored in the admission, the use of the process should be strictly managed to ensure that no deformation, not moisture, no rust. 2, the decoration of the ceiling with the boom is strictly prohibited to do electromechanical pipelines, line hanging with; electromechanical pipelines, lines, such as contradiction with the ceiling boom position, subject to the project technical staff agreed to change, not free to change, move boom. 3, hanging on the keel banned the laying of electromechanical pipes, lines. 4, light steel frame and cover panel installation should pay attention to protect the roof of a variety of pipelines, light steel skeleton of the boom, keel is not allowed to be fixed in the ventilation pipes and other equipment pieces. 5, in order to protect the finished product, cover the panel must be installed in the shed pipe, test the water, insulation and all other processes after the acceptance. 6, set a person responsible for the protection of finished products and found that the protection of damaged facilities, to timely recovery. 7, the process of all the written use by the two sides signed by the recognition, by the next process operations and product protection at the same time the person in charge to confirm the signature, and save the process of handing over the written materials, the next operation to prevent the finished product contamination, damage or loss Direct responsibility for the protection of finished products on the protection of finished products, supervision, inspection responsibility.

- Q: Seeking: light steel keel mineral wool board ceiling, the general how much money a square? (The installation is complete)

- Different regions, different brands are not the same price, we generally installed here to complete 1 square meters 50 to 60 yuan

- Q: Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The gypsum board closed should refer to the ceiling, behind the "light steel keel" is "special" indicate that the use of the ceiling required to use the "green gauze board" Keel is "light steel keel".

- Q: Ceiling light steel keel 50/60 in 60 on behalf of what

- Specifications model ah main keel 50 is 50 × 15 × 1.2 60 is 60 × 27 × 1.2

- Q: Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- When the hanging length of more than 1.5m should be set anti-support, reverse support is in the case of normal boom, from the lower end of the boom oblique ceiling installation to connect a rod, rod to have a certain stiffness, and the boom to form a Solid triangular. To prevent the ceiling in the air pressure when the upward deformation, the formation of dome, causing damage to the ceiling. The number of anti-support should be set according to the construction plan.

Send your message to us

High-Quality W Angle Ceiling Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords