Ceiling Profile Hook Channel Ceiling System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

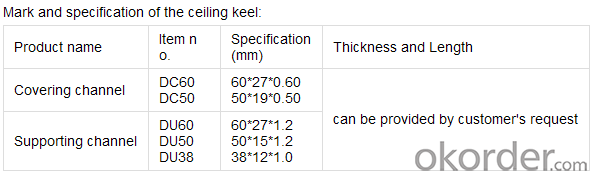

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: What is the general ceiling of indoor ceiling?

- Now a lot of aluminum buckle board, very cheap, the effect is also good

- Q: Construction works: light steel keel partition in a ceiling ceiling, the height should be calculated to the ceiling ceiling or calculated to the bottom of the concrete floor?

- Light steel keel wall is to rely on the ground and the floor at the end of the two connections to maintain stability, since the keel has been received at the end of the floor, of course, is calculated to the bottom of the floor rather than the top of the ceiling.

- Q: Light steel keel ceiling steps? How to use wood?

- Generally do not have to wood core board, and may be some special top, with wood core board to do with the annex.

- Q: Light steel keel ceiling one square meter how much money

- Now on the market of light steel keel ceiling is generally 30-40 / square meter, of course, different quality keel ceiling price is not the same, and now we come to understand the light steel keel ceiling installation method!

- Q: Light steel keel ceiling screw must be installed vertically? There are pictures.

- So that the vertical is the most easy to pull out, you pull things are subconsciously vertical pull, the most effort. So oblique, pull even more ~

- Q: Ceiling twenty square meters need light steel keel how many roots

- Light steel keel ceiling material ratio does not have a standard number, generally according to the shape of the room, height related.

- Q: Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Light steel keel has the following advantages: light steel keel long unchanged. Light steel keel, the surface of high galvanized, long no rust, more could not be pest ants. Light steel keel is non-combustible material, no fire hazard Light steel keel environmental protection beyond wood material; light steel keel installation no noise, connected firmly, and to ensure environmental health; light steel keel is a new ceiling material, widely used in home and engineering The Wooden wood ceiling damage: the absorption of air in the air, especially in the northeastern weather, thermal expansion and contraction, inevitable deformation, leading to gypsum board cracking and deformation; wood material easy insects, ants and other organisms, harmful to humans. Wood material strength is not enough, it is easy to produce gypsum board subsidence, deformation and other issues; code nail connection easy to loose, shedding wounding; woody materials flammable, easy to cause fire; wood material keel applications will use fire retardant coating, Material in the installation, there is a strong "formaldehyde" gas volatilization; wood keel in the installation, must use nail gun, the noise is great, and woods flying, stimulate the body skin; wood ceiling, partition is already eliminated A structure, the project has been not allowed to use. From the construction cost and cost of considering the difference between the two little, light steel keel construction costs lower.

- Q: Light steel keel ceiling installation detailed process

- Install the side keel: The installation of the edge keel should be designed according to the design requirements of the elastic line, along the horizontal column on the pillars of the L-shaped galvanized steel bar with self-tapping screws fixed on the embedded wood bricks, such as concrete studs, The spacing of the nails should be less than the distance between the keel.

- Q: Play light steel keel cut off how not to damage the ceiling

- Can be found after the next day keel fixed, the other side can be used to do vertical keel shape, and then package edge

- Q: Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- When the hanging length of more than 1.5m should be set anti-support, reverse support is in the case of normal boom, from the lower end of the boom oblique ceiling installation to connect a rod, rod to have a certain stiffness, and the boom to form a Solid triangular. To prevent the ceiling in the air pressure when the upward deformation, the formation of dome, causing damage to the ceiling. The number of anti-support should be set according to the construction plan.

Send your message to us

Ceiling Profile Hook Channel Ceiling System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords