Lightgage Steel Keel Ceiling Profile for Steel House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Specifications

1. Hot dip Galvanized

3. Grade: Q235, Q 345

4. Thickness:1.5 mm - 3.5mm

5. H: 100-350 B: 40-120.

China supplier buying gypsum drywall partition metal track

Material:hot dip galvanized steel

Surface treatment: roll coated

Application: ceiling grid system

Zinc content: 60-140g per sq.m

Factory sale price.OEM

Samples for free

Rustproof

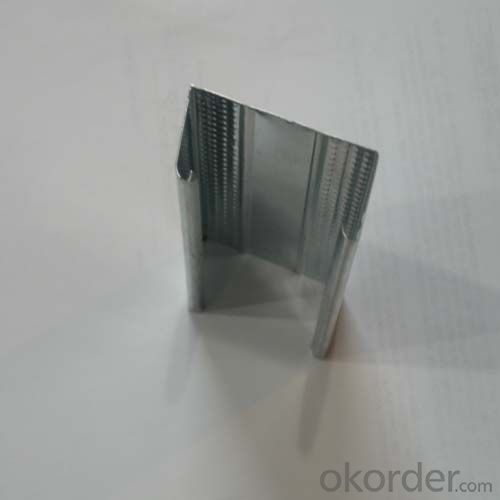

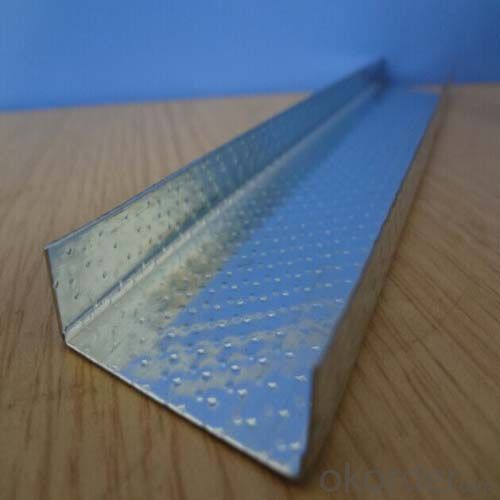

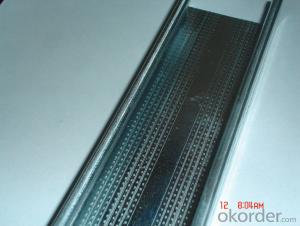

3.Image

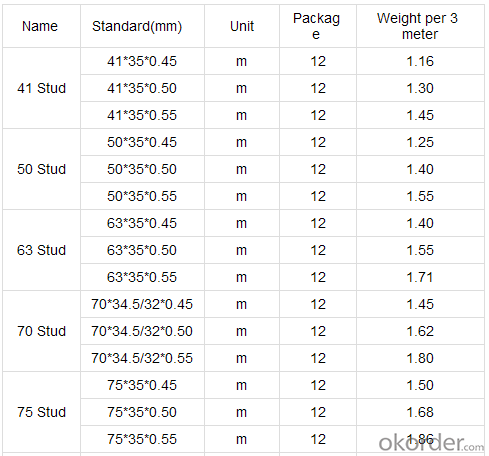

4.Detailed Specification

5.FAQ

A.Plasterboard Introduction:

Plasterbord is also called gypsum board or drywall. It differs from other panel-type building

products, such as plywood, hardboard, and fiberboard, because of its noncombustible core

and paper facers.

When joints and fastener heads are covered with a joint compound system,plasterboard

creates a continuous surface suitable for most types of interior decoration.

1.Environmental friendly

2.Non-combustible

3.Strong nail holding power

4.Heat & sound insulation

5.Smoothness ceiling board

6.Light weight in unit acreage

7.Square Edge or Tapered edge ceiling board

B.Application of Plasterboard

1. Residential-Flats, Bungalows, Villas, Farm houses.

2. Commercial- Small work places to corporate offices.

3. Hospitality- Clubs, Discs, Hotels, Restaurants, All types of functional places.

4. Healthcare- Clinics, Hospitals, Polyclinics.

5. Institutional- Schools, Colleges.

6. Entertainment- Auditoriums, Performance theaters, Studios.

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- 5, the installation of sub-keel 1> has been played by a good sub-keel sub-line, card sub-keel hanging pendant. 2> hanging sub-keel: according to the provisions of the provisions of the keel spacing, the sub-keel hanging hanging on the main keel, the design requirements, the general spacing of 500mm-600mm. 3> When the length of the keel to be a number of continuation of a long time, with the keel connection, hanging in the keel at the same time the connection, straighten the fixed. ?Install the cover panel, the installation of the panel before the end of the terminal equipment must be located on the ground and the various pipeline inspection and acceptance, before allowing the installation of the panel. Cover plate and light steel keel fixed method is: Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q: Please give valid certificate, thank you! The

- The keel of the ceiling needs to be re-examined: Detection parameters Keel: size deviation, mechanical properties; Accessories: size deviation, mechanical properties. Keel ceiling project quality acceptance project: Ceiling elevation, size, from the arch and shape should meet the design requirements. Test method: observation; scale inspection. The material, variety, specifications, regiment and color of the facing material should meet the design requirements. When the facing material is a glass plate, use safety glass or take reliable safety measures. Inspection method: observation; check product certificate of competency, performance testing report and admission inspection records. Finishes should be tightly installed. The overlapping width of the facing material and the keel should be greater than two-thirds of the width of the keel. Test method: observation; hand pull check; scale check. Boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be surface corrosion treatment; wood keel should be anti-corrosion, fire treatment. Inspection methods: observation; foot check; check product certificate of competency, admission acceptance records and hidden engineering acceptance records.

- Q: Light steel keel ceiling which brand is better

- You can go to the forum to consult the other owners to see everyone's views

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q: What is a man ceiling, what is not a man ceiling?

- Master ceiling will use a better strength of the special boom and keel. And leave the hole. Not on the use of ordinary keel can be

- Q: PVC plastic buckle plate ceiling with what keel ah?

- There may be putty or gypsum did not dry on the latex paint

- Q: Light steel keel paper gypsum board ceiling construction process

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Package workers a square meter twenty yuan or so, Bao Gong Bao material will be about a square meter 70 yuan,

- Q: Will the light steel keel ceiling be deformed?

- Generally not Please adopt If you acknowledge my answer, please accept it in time, ~ If you acknowledge my answer, please click on the "Accept Satisfactory Answer" button ~ ~ Mobile phone questions friends in the upper right corner of the client evaluation point [satisfaction] can be. ~ Your adoption is the driving force of my progress ~ ~ O (∩ _ ∩) O, remember praise and adoption, help each other

- Q: Light steel keel ceiling boom and whether the strong electric lines can be common

- Construction regulations are not allowed.

Send your message to us

Lightgage Steel Keel Ceiling Profile for Steel House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords