Drywall Metal Studs and Tracks ISO 9001 Drywall Metal Studs and Tracks ISO 9001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

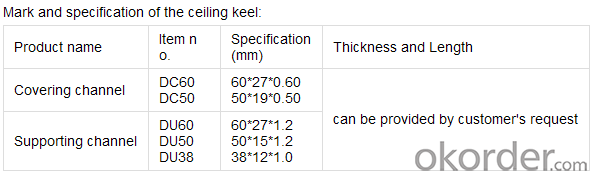

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q:PVC plastic buckle plate ceiling with what keel ah?

- Plastic buckle, it should be wooden keel, is the wooden side. If it is aluminum buckle, it should be light steel keel.

- Q:Gypsum board ceiling side keel with a good side of the wood or supporting the light keel edge keel good?

- Of course, is the use of supporting the light steel keel (edge keel) better, and the construction (operation) will be more convenient.

- Q:Will the use of light steel keel and gypsum board ceiling decoration home ceiling, how much money ah?

- Flat top artificial materials 55 yuan a square, the opposite sex 75 to 80 yuan a square

- Q:Light steel keel ceiling material calculation method?

- Plate in square meters, gypsum board for 3 m * 1.2 m / per, ceiling area divided by the area of each gypsum board is the number of gypsum board used, the appropriate put some loss. The main keel per square meter with one meter can be calculated, pay keel per square meter with 3 meters, the boom calculated by two per square meter, the length of the floor height in accordance with the height of the ceiling can be reduced. Suspension fixed parts according to the number of boom configuration, hanging pieces of each square meter 2 calculation, with the number of boom. Hanging by 3-4 per square meter can be. The total number multiplied by the total area can be summed up, plus wealth can be

- Q:Light steel keel ceiling calculation method

- Per square meter ceiling need: The main keel 1 meter, deputy keel 2 meters, stays up the keel 2 meters, while the keel for the ceiling around the total length (with the room size, shape). If you want to calculate in detail, it is necessary to see how the layout of the keel on the drawings. for example: The main keel spacing of 1.2 meters, along the length of the layout of the room; vice keel spacing 0.6 m; stays keel spacing 0.6 m; room length 6 m, width 4.5 m. The main keel is: 4.5 ÷ 1.2-1 = 2.75 (root), rounding requires three main keels, keel spacing adjusted to 4.5 ÷ (3 +1) = 1.125 meters. The main keel needs: 6 × 3 = 18 meters. Vice keel is: 6 ÷ 0.6-1 = 9 (root), keel spacing just to meet the design requirements of 0.6 meters. Vice keel need: 4.5 × 9 = 40.5 meters. Hold the keel is: 4.5 ÷ 0.6-1 = 6.5 (root), rounding requires 7 stays keel, keel spacing adjusted to 4.5 ÷ (7 +1) = 0.56 m. Hold the keel need to: 6 × 7 = 42 meters. Side keel need: (6 + 4.5) × 2 = 21 meters. In the material plan, each should also be added to the loss of 1 to 3% OK!

- Q:Light steel keel ceiling effect is what

- Light steel keel wall ceiling general fire can be over. And cheap, with the use of peace of mind. Compared with the wooden keel ceiling, the main advantage is fire, such as ktv, bars and other public places with much more.

- Q:I am a novice . The How the keel is fixed on the ceiling of the hairy house. The Also gypsum board ceiling gypsum board is how to install on the keel I think: it will not fall? Is it to take nails or what glue up? What is the use of the boom (the ceiling will seem to use ..)

- There are standard hanging with the nails, fixed on the keel, will not fall, Of course, this is also a construction standard, not the same shed with the material will be different.

- Q:What is the yellow water to the keel brush before making the light steel keel ceiling?

- You do light steel keel top before the dragon to brush some yellow water, no need ah, light steel keel are galvanized Yeah, gypsum board do not have to deal with ah.

- Q:Play light steel keel cut off how not to damage the ceiling

- Can be found after the next day keel fixed, the other side can be used to do vertical keel shape, and then package edge

- Q:Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel selection with the weight of the ceiling, rather than height.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Metal Studs and Tracks ISO 9001 Drywall Metal Studs and Tracks ISO 9001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords