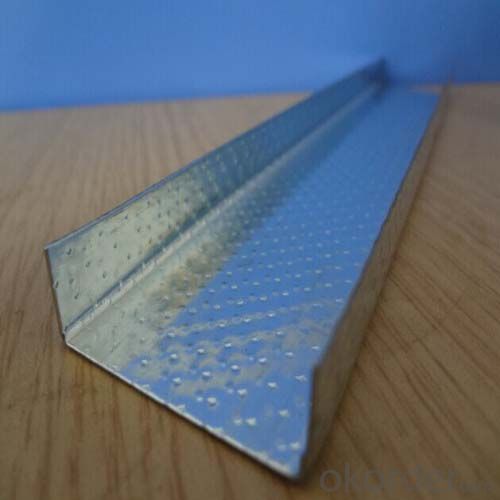

Light Steel Keel Made In China For Home Fecor

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

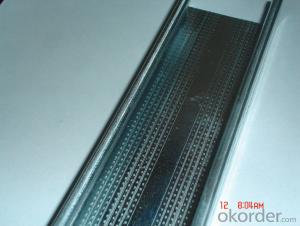

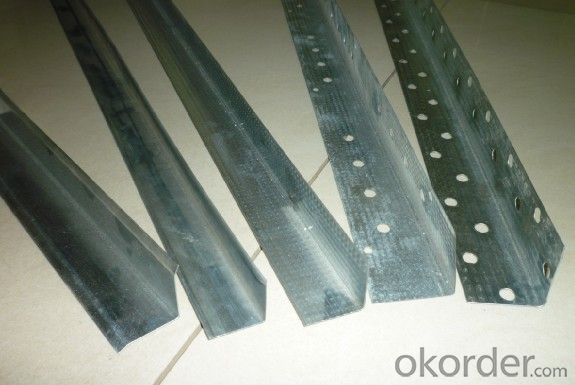

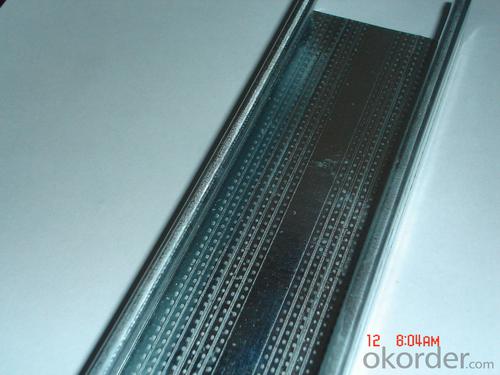

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

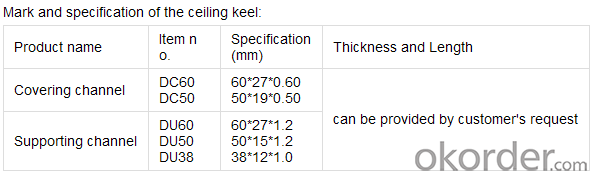

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: Light steel keel ceiling how to read complex drawings

- Look at the drawings do not have to see so complicated, as long as the success of what is known. As for the light keel wanted to do what to do.

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- 5, the installation of sub-keel 1> has been played by a good sub-keel sub-line, card sub-keel hanging pendant. 2> hanging sub-keel: according to the provisions of the provisions of the keel spacing, the sub-keel hanging hanging on the main keel, the design requirements, the general spacing of 500mm-600mm. 3> When the length of the keel to be a number of continuation of a long time, with the keel connection, hanging in the keel at the same time the connection, straighten the fixed. ?Install the cover panel, the installation of the panel before the end of the terminal equipment must be located on the ground and the various pipeline inspection and acceptance, before allowing the installation of the panel. Cover plate and light steel keel fixed method is: Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q: Light steel keel ceiling which brand is better

- You can go to the forum to consult the other owners to see everyone's views

- Q: Why the ceiling keel

- Ceiling keel is what we often see the ceiling, especially the shape of the ceiling, are made of keel frame, and then covered with gypsum board made. Ceiling keel is made of light steel, for the ceiling of the main material, it is connected with the floor through the screw, used to fix the ceiling or objects.

- Q: Light steel keel ceiling calculation method

- Per square meter ceiling need: The main keel 1 meter, deputy keel 2 meters, stays up the keel 2 meters, while the keel for the ceiling around the total length (with the room size, shape). If you want to calculate in detail, it is necessary to see how the layout of the keel on the drawings. for example: The main keel spacing of 1.2 meters, along the length of the layout of the room; vice keel spacing 0.6 m; stays keel spacing 0.6 m; room length 6 m, width 4.5 m. The main keel is: 4.5 ÷ 1.2-1 = 2.75 (root), rounding requires three main keels, keel spacing adjusted to 4.5 ÷ (3 +1) = 1.125 meters. The main keel needs: 6 × 3 = 18 meters. Vice keel is: 6 ÷ 0.6-1 = 9 (root), keel spacing just to meet the design requirements of 0.6 meters. Vice keel need: 4.5 × 9 = 40.5 meters. Hold the keel is: 4.5 ÷ 0.6-1 = 6.5 (root), rounding requires 7 stays keel, keel spacing adjusted to 4.5 ÷ (7 +1) = 0.56 m. Hold the keel need to: 6 × 7 = 42 meters. Side keel need: (6 + 4.5) × 2 = 21 meters. In the material plan, each should also be added to the loss of 1 to 3% OK!

- Q: Home ceiling with green steel skeleton or wooden frame

- Of course it is steel dragon skeleton!

- Q: Construction schedule of light steel keel ceiling

- 2 people, about 3 days. Good workers are faster

- Q: Do steel keel ceiling, need to use white latex?

- As if you can buy a roll of tape. Gypsum board gap filled with putty, with latex to crack the paper tape on the outside. Nails coated with anti-rust paint. Finally, the whole scraping putty. Before the people to do 400 square meters with a variety of woodworking, a total of half a barrel Big bucket

- Q: The construction of the lightweight steel keel gypsum board ceiling

- Note that the material can be used to mark, such as hanging bars, expansion screws, the main keel, vice keel. Aluminum plate.

- Q: Light steel keel ceiling installation detailed process

- Simpler. Expand the screw to fit and connect the hanging bars. 2, arranged the main keel, 3, deputy keel. Finish

Send your message to us

Light Steel Keel Made In China For Home Fecor

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords