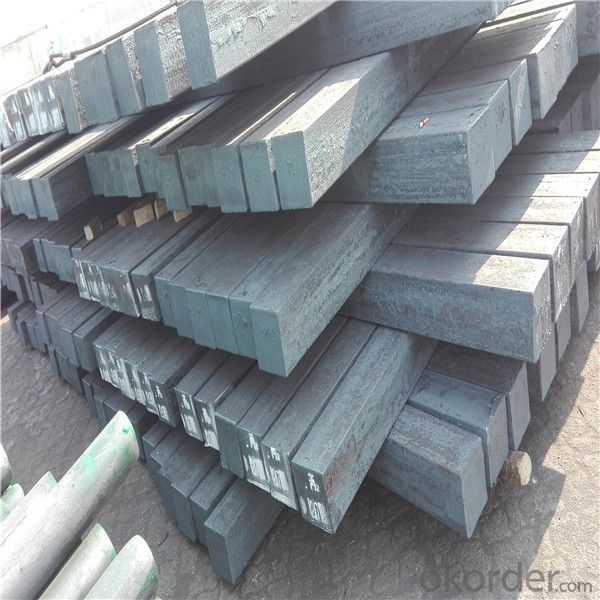

Mild steel billet for sale low price made in china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15542 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet :

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the main types of steel billet rolling mills?

- The main types of steel billet rolling mills include continuous, semi-continuous, and reversing mills.

- Q: How are steel billets handled during transportation?

- Steel billets are typically handled during transportation using specialized equipment such as cranes or forklifts. They are typically secured with chains or straps to prevent any movement or shifting during transit. Additionally, proper packaging and labeling are important to ensure safe and efficient handling during transportation.

- Q: How are steel billets used in the production of railway components?

- Railway components rely heavily on steel billets during the production process. These billets, which are essentially semi-finished steel products, serve as the foundation for manufacturing various railway components such as rails, wheels, axles, and structural parts. To create railway components, steel billets are first heated to a specific temperature, enhancing their malleability. This crucial heating process enables easy shaping and forming of the steel into the desired component. Once the billets reach the required temperature, they proceed to the next stage of production. Here, they undergo processes like rolling, forging, and machining to transform them into the final shape and size needed for the specific railway component. For example, in the production of railway rails, heated steel billets pass through a series of rolling mills, gradually shaping and elongating them into the desired rail profile. Similarly, for wheels and axles, billets are forged and machined to achieve the necessary dimensions and surface finish. The utilization of steel billets ensures that the resulting railway components possess strength, durability, and the ability to withstand the heavy loads and stresses associated with railway operations. The quality and characteristics of the steel billets greatly influence the performance and lifespan of the railway components. In summary, steel billets play a critical role in producing railway components by providing the raw material that is shaped, formed, and processed into the essential final products for the safe and efficient operation of the railway system.

- Q: which companies are, and how the billet sales, how can we sell billet to ask for advice, thank you

- As for sales, one to information, two to high quality and low price, three to find relations.

- Q: What are the common surface treatments for steel billets?

- There are several common surface treatments for steel billets, which are commonly used to enhance their performance and protect them against corrosion. Some of the most common surface treatments for steel billets include: 1. Hot-dip galvanizing: This process involves immersing the steel billets in a bath of molten zinc, which creates a protective zinc coating on the surface. Hot-dip galvanizing provides excellent corrosion resistance and is commonly used in outdoor applications. 2. Electroplating: Electroplating involves passing an electric current through a solution containing metal ions, causing them to deposit onto the steel billets' surface. This process can be used to apply various metals like nickel, chromium, or zinc, depending on the desired properties and appearance. 3. Powder coating: Powder coating involves spraying a dry powder onto the steel billets' surface, which is then heated to fuse and form a protective coating. This method offers a wide range of color options, excellent durability, and resistance to chemicals, weathering, and UV radiation. 4. Phosphating: Phosphating is a chemical treatment that involves applying a phosphate coating onto the steel billets' surface. This process improves corrosion resistance and promotes paint adhesion, making it a suitable treatment before painting or powder coating. 5. Blackening: This surface treatment involves applying a chemical solution to the steel billets, which creates a black oxide layer on the surface. Blackening enhances the steel's appearance and provides mild corrosion resistance, making it suitable for decorative purposes. 6. Passivation: Passivation is a process that involves treating the steel billets with an acid solution to remove any contaminants and create a passive oxide layer on the surface. This treatment improves the steel's corrosion resistance and is commonly used for stainless steel billets. These surface treatments for steel billets are widely used in various industries to enhance their properties and increase their lifespan. The choice of treatment depends on the specific requirements, such as the intended application, desired appearance, and environmental conditions in which the steel billets will be used.

- Q: What are the different types of steel billet forging defects?

- There are several different types of steel billet forging defects that can occur during the forging process. These defects can have various causes and can impact the quality and integrity of the final forged product. Some of the common types of defects include: 1. Surface cracks: These are cracks that occur on the surface of the billet. They can be caused by excessive heating or cooling, improper forging techniques, or the presence of impurities in the steel. 2. Internal voids: These are cavities or voids that form within the billet. They can be caused by incomplete filling of the mold, improper venting, or the presence of gases trapped within the steel. 3. Inclusions: These are foreign materials or impurities that are present within the billet. They can include non-metallic particles, such as oxides or sulfides, or metallic impurities, such as slag. Inclusions can weaken the structure of the steel and reduce its overall quality. 4. Segregation: This refers to the non-uniform distribution of alloying elements within the billet. It can occur during the cooling process and can result in areas of the steel with different mechanical properties. This can lead to inconsistencies in the final product. 5. Dimensional inaccuracies: These defects refer to deviations from the desired shape or size of the billet. They can be caused by improper tooling or die design, inadequate heating or cooling processes, or improper handling during forging. 6. Grain structure abnormalities: The grain structure of the steel can be affected by various factors, such as improper heating or cooling rates. Abnormal grain structures can weaken the steel and reduce its mechanical properties. It is important to identify and address these defects during the production process to ensure the quality and reliability of the final forged product. Quality control measures, such as non-destructive testing and visual inspections, can help to detect and rectify these defects before the finished product is delivered to the customer.

- Q: How do steel billets contribute to the overall seismic resistance of a structure?

- Steel billets play a crucial role in enhancing the overall seismic resistance of a structure. Seismic resistance refers to a structure's ability to withstand the forces and vibrations caused by earthquakes. Firstly, steel billets are commonly used as reinforcement in concrete structures. When placed within the concrete, they provide additional strength and durability to the structure, making it more resistant to seismic forces. The high tensile strength of steel billets allows them to absorb and distribute the seismic energy more effectively, reducing the risk of structural failure during an earthquake. Moreover, steel billets can be used to create specialized structural elements, such as braces or shear walls. These elements are strategically placed within the structure to resist lateral forces caused by earthquakes. By using steel billets, these elements can effectively absorb and dissipate the seismic energy, preventing it from causing significant damage to the overall structure. Furthermore, steel billets can be employed in the construction of seismic dampers. These dampers are devices designed to absorb and dissipate the energy generated by seismic events. By installing steel billet-based dampers, the structure can effectively reduce the amount of seismic energy transferred to the building, thus minimizing potential damage. Additionally, steel billets offer excellent ductility, which is the ability to deform without breaking. During an earthquake, structures undergo significant movements and vibrations. The ductile nature of steel allows it to bend and flex under these forces, absorbing the seismic energy and preventing sudden and catastrophic failure of the structure. In conclusion, steel billets contribute to the overall seismic resistance of a structure by providing additional strength and durability, creating specialized structural elements, allowing the construction of seismic dampers, and offering excellent ductility. Their use enhances the structure's ability to withstand seismic forces, reducing the risk of damage and ensuring the safety of the occupants.

- Q: What are the common surface defects in steel billets during reheating?

- Several surface defects may occur during the reheating process of steel billets, which can negatively impact the quality and integrity of the final product. Some of the most common surface defects observed in steel billets during reheating are as follows: 1. Scale Formation: When steel billets are subjected to high temperatures, a layer of iron oxide, referred to as scale, can develop on the surface. Scale is brittle and can easily crack or flake off, resulting in a rough and uneven surface. 2. Decarburization: Exposing steel billets to high temperatures causes the loss of carbon from the surface, known as decarburization. This leads to a decrease in carbon content on the surface, making it susceptible to cracking, reduced hardness, and poor mechanical properties. 3. Surface Oxidation: During reheating, steel billets can undergo oxidation when exposed to oxygen in the air. This results in the formation of a thin layer of oxide on the surface, affecting the surface finish and potentially reducing the steel's corrosion resistance. 4. Overheating: If the reheating process causes localized melting or partial melting of the steel billets, it is referred to as overheating. This can lead to surface irregularities, such as pits, cracks, or blisters, compromising the integrity of the billets. 5. Hot Spots: Uneven heating of the steel billets can cause hot spots to form on the surface. These localized areas of excessive heat can result in surface defects like warping, cracking, scorching, or discoloration. 6. Surface Contamination: During reheating, steel billets may come into contact with contaminants such as dirt, oil, or other foreign materials. These contaminants can adhere to the surface, leading to surface defects like stains, pitting, or an uneven surface finish. 7. Thermal Shock: Rapid temperature changes during reheating can cause thermal shock, resulting in surface defects like cracks or distortions. This can occur when the steel billets are exposed to water or a cooling medium, or when there are significant temperature differences across the surface. To minimize these surface defects in steel billets during reheating, it is essential to employ proper heating techniques, control heating rates, and use protective coatings or atmospheres. Additionally, regular inspection and quality control measures can help identify and mitigate surface defects before they impact the final product's quality.

- Q: What are the potential applications of steel billets in the oil and gas sector?

- Steel billets have a wide range of potential applications in the oil and gas sector due to their excellent mechanical properties and durability. Here are some of the potential applications: 1. Drill pipes and casings: Steel billets can be used to manufacture drill pipes and casings, which are essential components in the drilling process. These pipes and casings need to withstand high pressure and extreme temperatures, and steel billets provide the necessary strength and toughness required for such demanding conditions. 2. Pipelines: Steel billets can be used to produce seamless or welded steel pipes for oil and gas pipelines. These pipes are used for the transportation of oil, gas, and other petroleum products over long distances. Steel billets ensure the durability and integrity of the pipelines, as they can withstand high pressure, corrosion, and impact. 3. Offshore structures: Steel billets are also used in the construction of offshore platforms, drilling rigs, and other structures used in the extraction and production of oil and gas from offshore reserves. These structures are exposed to harsh marine conditions, including saltwater, wind, and waves. Steel billets provide the necessary strength and corrosion resistance to withstand these challenging environments. 4. Pressure vessels and storage tanks: Steel billets can be utilized to manufacture pressure vessels and storage tanks used for the storage and transportation of oil, gas, and various chemicals. These vessels and tanks need to withstand high pressure and temperature variations without compromising safety. Steel billets provide the required strength and resistance against corrosion and leakage. 5. Equipment components: Steel billets are also used to fabricate various components and equipment used in the oil and gas sector, such as valves, flanges, fittings, and connectors. These components play a crucial role in the operation and maintenance of oil and gas facilities, and steel billets ensure their reliability and performance. Overall, the potential applications of steel billets in the oil and gas sector are vast and diverse, covering various stages of exploration, production, transportation, and storage. Their exceptional strength, durability, and resistance to extreme conditions make them an ideal material choice for critical applications in this industry.

- Q: What is the role of steel billets in the construction of high-rise buildings?

- Steel billets play a crucial role in the construction of high-rise buildings as they serve as the raw material for manufacturing structural steel sections such as beams, columns, and reinforcement bars. These sections are essential for providing strength, stability, and load-bearing capacity to the building's framework. Steel billets are heated, molded, and shaped into these sections, which are then assembled to form the structural skeleton of the building. Their high strength-to-weight ratio and durability make steel billets an ideal choice for constructing tall buildings that can withstand various weather conditions and structural loads.

Send your message to us

Mild steel billet for sale low price made in china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15542 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords