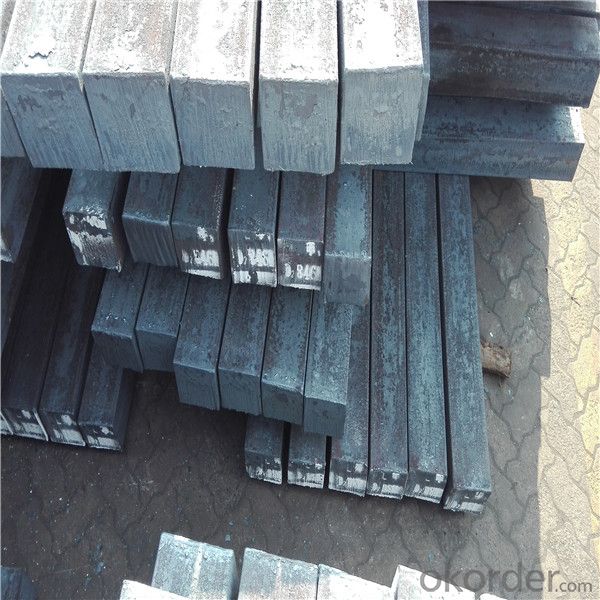

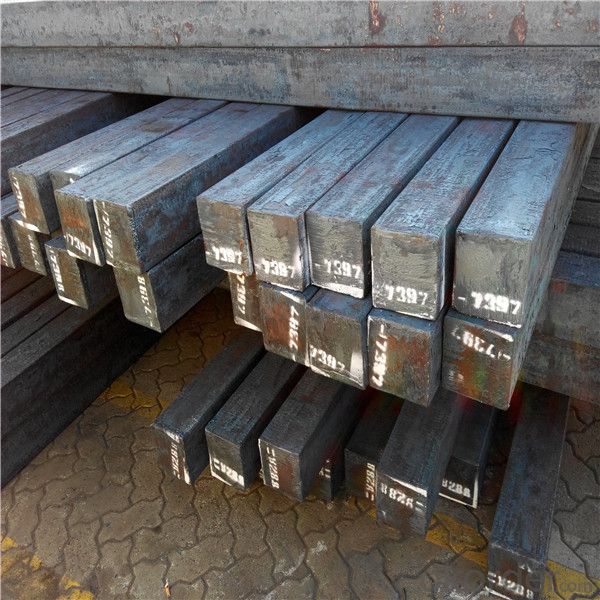

Steel billet in low price as steel material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 21643 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets different from steel ingots?

- Steel billets and steel ingots are both intermediate products in the steel manufacturing process, but they differ in terms of their shape and size. Steel billets are smaller and have a square or rectangular cross-section, typically measuring less than 36 square inches. In contrast, steel ingots are larger and have a more irregular shape, often weighing several tons. Additionally, steel billets are typically produced using continuous casting methods, while steel ingots are typically made through traditional ingot casting processes.

- Q: Can steel billets be painted or coated for decorative purposes?

- Steel billets can indeed be painted or coated to achieve decorative purposes. By painting or coating steel billets, not only is their appearance improved, but they are also safeguarded against corrosion and other environmental factors. A variety of paints and coatings, including epoxy, powder coating, and metallic finishes, can be utilized to achieve the desired decorative effect. These coatings can be applied to steel billets using methods such as spray painting, electrostatic coating, or hot-dipping. To ensure a strong bond and long-lasting decorative finish, it is crucial to properly prepare the surface of the steel billets before applying the paint or coating.

- Q: What are the main factors affecting the machinability of alloy steel billets?

- Several key factors influence the machinability of alloy steel billets. Firstly, the machinability can be affected by the alloy composition of the steel. Different alloying elements, including chromium, nickel, molybdenum, and vanadium, have varying impacts on the machinability. Chromium and molybdenum, which form hard carbides, tend to decrease machinability, while nickel and vanadium, which promote the formation of softer carbides, can enhance machinability. Secondly, the heat treatment of the alloy steel billets significantly impacts machinability. Processes such as annealing, normalizing, or quenching and tempering can alter the microstructure and hardness of the steel. Proper heat treatment can improve machinability by reducing hardness and increasing toughness, while improper heat treatment can result in increased hardness and decreased machinability. Thirdly, the presence of impurities and inclusions in the alloy steel billets can affect machinability. Inclusions, such as sulfides, oxides, and non-metallic particles, can cause tool wear and chip breakability issues during machining. Therefore, the cleanliness and purity of the alloy steel billets are crucial factors in determining machinability. Furthermore, the mechanical properties of the alloy steel, such as hardness, strength, and ductility, can influence machinability. Higher hardness and strength levels can make machining more challenging, while increased ductility and toughness can improve machinability. Lastly, the cutting conditions and machining parameters, including cutting speed, feed rate, depth of cut, and tool material, also impact machinability. Optimal cutting conditions should be selected based on the specific alloy steel composition and desired machinability. Adequate cooling and lubrication during machining are also essential to reduce friction and heat, preventing tool wear and improving machinability. In conclusion, the machinability of alloy steel billets is influenced by factors such as alloy composition, heat treatment, impurities and inclusions, mechanical properties, and cutting conditions. Proper consideration of these factors can help optimize the machinability of alloy steel and ensure efficient and effective machining processes.

- Q: How are steel billets forged into shape?

- Steel billets are forged into shape through a process called hot forging, which involves heating the billet to a specific temperature and then applying pressure to shape it using a forging press or hammer. This process helps to refine the grain structure of the steel, improving its strength and mechanical properties.

- Q: What are the different methods of steel billet surface etching?

- There are several different methods of steel billet surface etching that are commonly used in various industries. These methods include chemical etching, electrolytic etching, and laser etching. 1. Chemical etching: This method involves immersing the steel billet in a chemical solution, usually an acid, that selectively removes a thin layer of material from the surface. The choice of the chemical solution depends on the specific requirements of the etching process, such as the desired depth and pattern. Commonly used chemicals for steel etching include hydrochloric acid, nitric acid, and ferric chloride. 2. Electrolytic etching: In this method, an electric current is passed through the steel billet while it is immersed in an electrolyte solution. The current causes a controlled dissolution of the surface metal, resulting in a desired etched pattern. Electrolytic etching offers precise control over the etching process and can produce intricate and detailed designs. It is often used for marking or labeling steel billets with logos, serial numbers, or other identification marks. 3. Laser etching: Laser etching is a non-contact and highly precise method of surface etching. It involves using a laser beam to selectively remove material from the steel billet surface. The laser beam is directed and controlled by computer software, allowing for intricate and customizable designs. Laser etching can be used to create permanent markings, logos, or patterns on steel billets. It is widely used in industries such as automotive, aerospace, and electronics. Each of these methods has its advantages and limitations, and the choice of the etching method depends on factors such as the desired design, the material properties of the steel billet, and the production requirements.

- Q: What are the different surface finishes available for alloy steel billets?

- There are several different surface finishes available for alloy steel billets, depending on the specific requirements and applications. Some of the common surface finishes include: 1. Hot rolled: This is the most common surface finish for alloy steel billets. It is achieved by rolling the steel billet at a high temperature, which results in a rough and scaled surface. 2. Cold drawn: This surface finish is achieved by pulling the steel billet through a die at room temperature. It provides a smooth and polished surface, with improved dimensional accuracy and surface quality. 3. Peeled: In this process, a layer of material is removed from the surface of the steel billet using a peeling tool. It results in a smooth and shiny surface finish, with improved surface quality and dimensional accuracy. 4. Ground: This surface finish is achieved by grinding the surface of the steel billet using abrasive wheels or belts. It provides a smooth and uniform surface finish, with improved surface quality and dimensional accuracy. 5. Turned: In this process, the steel billet is rotated against a cutting tool, which removes material from the surface and creates a smooth and polished finish. It is commonly used for high precision applications where a smooth surface finish is required. 6. Polished: This surface finish is achieved by polishing the steel billet using abrasive compounds and buffing wheels. It provides a mirror-like finish, with improved aesthetic appeal and corrosion resistance. It is important to select the appropriate surface finish based on the specific requirements of the application, such as dimensional accuracy, surface quality, aesthetic appeal, and corrosion resistance.

- Q: What are the potential applications of steel billets in the transportation industry?

- In the transportation industry, steel billets offer a wide range of potential applications. One important use is their role in manufacturing various parts and components for automobiles, including engine blocks, chassis, suspension systems, and wheels. These critical components require the strength and durability that steel billets provide, ensuring the safety and reliability of vehicles. Furthermore, steel billets are commonly employed in the production of railway tracks, guaranteeing the stability and longevity of rail infrastructure. Their high strength and resistance to wear and tear make them an ideal choice, enabling them to withstand heavy loads and extreme weather conditions. Additionally, steel billets find application in ship and boat construction. The marine industry relies on their strength and corrosion resistance to build hulls, decks, and various structural components. Steel billets also play a crucial role in bridge construction, providing the necessary strength and structural integrity to support heavy traffic loads. Moreover, steel billets are extensively used in the manufacturing of aircraft parts and components. The aviation industry demands materials with an exceptional strength-to-weight ratio, and steel billets meet this requirement. They are utilized in the production of landing gear, engine mounts, and other critical aircraft structures. In summary, the potential applications of steel billets in the transportation industry are vast and diverse. Their strength, durability, and resistance to wear and tear make them indispensable for the production of parts and components in automobiles, railway tracks, ships, boats, aircraft, and bridges. Steel billets contribute to the safety, reliability, and efficiency of transportation systems, making them an essential material in this industry.

- Q: How are steel billets used in the manufacturing of railway components?

- Steel billets are an essential raw material used in the manufacturing of railway components. These billets serve as the starting point for the production of various components such as rails, wheels, axles, and other structural parts. To begin with, steel billets are heated in a furnace to a specific temperature to make them more malleable and easier to shape. Once heated, the billets are then passed through a series of rolling mills, where they are progressively shaped into the desired form. For instance, to manufacture railway tracks, the heated billets are rolled and shaped into long continuous bars of steel known as rails. These rails are then cut to the required length and undergo further processes such as straightening, grinding, and drilling to meet the necessary specifications. Similarly, steel billets are also used in the manufacturing of railway wheels and axles. The heated billets are rolled and shaped into round bars, which are then further processed to form the wheel and axle components. These components undergo additional processes such as heat treatment, machining, and testing to ensure their strength, durability, and ability to withstand the heavy loads and stresses associated with railway operations. Furthermore, steel billets are utilized in the production of other railway components such as couplers, buffers, and suspension systems. These billets are shaped and processed according to the specific requirements of each component to ensure their proper functioning and compatibility with the overall railway system. In summary, steel billets are a critical ingredient in the manufacturing of railway components. They are transformed through heating and rolling processes to create various parts such as rails, wheels, axles, and other structural elements. These components are then further processed and tested to ensure their quality, reliability, and compliance with the demanding standards of the railway industry.

- Q: Can steel billets be used in the production of electrical appliances?

- Yes, steel billets can be used in the production of electrical appliances. Steel billets are semi-finished products that are typically used to produce various steel products, including electrical appliances. The steel billets can be further processed and shaped into different components required for electrical appliances, such as casings, frames, brackets, and other structural parts. The use of steel provides strength, durability, and corrosion resistance, making it suitable for the demanding requirements of electrical appliances. Additionally, steel is a widely available and cost-effective material, making it a preferred choice for manufacturing electrical appliances.

- Q: How are steel billets cooled after the manufacturing process?

- Steel billets are typically cooled after the manufacturing process using methods such as air cooling, water quenching, or accelerated cooling techniques.

Send your message to us

Steel billet in low price as steel material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 21643 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords