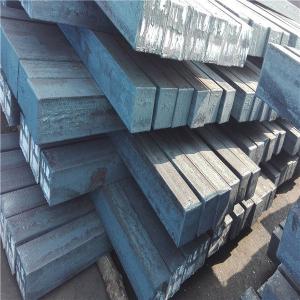

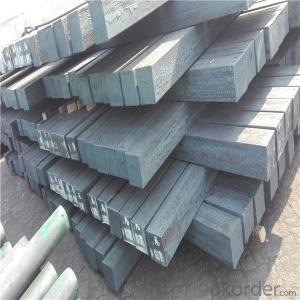

Steel billet from China for sale in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16542 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Can steel billets be used in the production of railway tracks?

- Yes, steel billets can be used in the production of railway tracks. Steel billets are semi-finished products that are commonly used in the manufacturing of various steel products, including railway tracks. Railway tracks require high strength and durability to withstand the weight and movement of trains. Steel billets, which are typically made from carbon steel or alloy steel, provide the necessary strength and structural integrity required for railway tracks. These billets can be further processed and shaped into rails through hot rolling or other manufacturing processes. The final rails are then installed on railway tracks to provide a smooth and safe surface for train movement. Therefore, steel billets are an essential raw material in the production of railway tracks.

- Q: What are the different heat treatment processes for alloy steel billets?

- There are several different heat treatment processes for alloy steel billets, including annealing, normalizing, quenching, and tempering. Annealing involves heating the billets to a high temperature and then slowly cooling them to relieve internal stresses and improve ductility. Normalizing is similar to annealing but involves air cooling instead of slow cooling. Quenching involves rapidly cooling the billets in a liquid medium, such as oil or water, to increase hardness and strength. Tempering is done after quenching and involves reheating the billets to a specific temperature and then cooling them slowly to reduce brittleness and improve toughness.

- Q: Is there an export duty? Or is there a tax refund?

- Your specification 13*13*6 or 12 meters, this is a square cross section, so 7207120000 this can not be used, your billet carbon content is 0.17 to 0.23% less than 0.25%, so we must use the following7207190000 Other Billets with carbon content less than 0.25%Export tax refund: 0%MFN country of import tariff: 2%General customs duties: 11%Export tariff rate: 0%VAT: 17%

- Q: What are the different methods of shaping steel billets?

- There are several different methods of shaping steel billets, each with its own advantages and applications. Some of the common methods include forging, rolling, extrusion, and casting. 1. Forging: Forging is a process in which the steel billet is shaped by applying pressure through the use of hammers or presses. This method allows for precise shaping and can produce complex shapes with high strength and durability. Forging is commonly used in manufacturing components for automotive, aerospace, and construction industries. 2. Rolling: Rolling is a process that involves passing the steel billet through a series of rollers to reduce its thickness and shape it into various forms such as sheets, plates, or bars. This method is highly efficient and can produce large quantities of steel products with consistent dimensions and surface finish. Rolling is commonly used in the production of structural steel, pipes, and tubes. 3. Extrusion: Extrusion is a process in which the steel billet is forced through a die to create a desired shape. This method is particularly suitable for producing long and continuous profiles with complex cross-sections, such as rods, tubes, and wire. Extrusion allows for precise control over the shape and dimensions of the final product and is commonly used in the manufacturing of aluminum window frames, automotive parts, and electrical conductors. 4. Casting: Casting is a method in which molten steel is poured into a mold and allowed to solidify into the desired shape. This process is versatile and can produce intricate and large-scale components with minimal material waste. Casting is commonly used in the production of steel ingots, pipes, and large structural components. These methods of shaping steel billets offer different advantages in terms of efficiency, precision, and versatility. The choice of method depends on the specific requirements of the desired steel product, including size, shape, strength, and cost-effectiveness.

- Q: Are steel billets prone to corrosion?

- Corrosion is not an inherent issue for steel billets. However, the likelihood of corrosion occurring depends on the specific steel type used and the environmental conditions in which they are placed. For instance, stainless steel billets possess a considerable amount of chromium, resulting in the formation of a protective layer on the surface that greatly enhances their resistance to corrosion. Conversely, carbon steel billets lack this protective layer, leading to increased vulnerability to corrosion. The presence of moisture, oxygen, and particular chemicals can expedite the corrosion process. Therefore, it is essential to handle and store steel billets appropriately, while also applying suitable coatings or treatments to minimize the risk of corrosion.

- Q: What is the role of steel billets in the construction of underground tunnels?

- The construction of underground tunnels heavily relies on steel billets, which are cylindrical steel bars. These bars act as the primary raw material for manufacturing various structural components that are crucial in guaranteeing the stability and safety of the tunnel. One significant use of steel billets is in the production of rebar, also known as reinforcing bar. Rebars are inserted into the concrete walls and floors of the tunnel to provide tensile strength and prevent cracking or collapsing under the immense pressure exerted by the surrounding soil or water. These steel bars reinforce the concrete, making it more durable and resistant to deformation, ultimately enhancing the overall structural integrity of the tunnel. Moreover, steel billets are also utilized to create other essential tunnel components, including tunnel segments and steel arches. Tunnel segments are precast concrete elements that form the lining of the tunnel, often incorporating steel reinforcement for added strength. On the other hand, steel arches are employed in constructing tunnel roofs to offer extra support and stability. Additionally, steel billets are employed in the fabrication of various tunnel reinforcement systems like rock bolts and ground anchors. These systems help secure loose or unstable rock formations, preventing them from collapsing and jeopardizing the stability of the tunnel. Steel billets are also used in manufacturing tunnel supports such as steel ribs and beams, which provide additional strength and rigidity to the tunnel structure. In conclusion, steel billets are critical in the construction of underground tunnels. By being transformed into rebar, tunnel segments, steel arches, and reinforcement systems, they play a vital role in ensuring the structural integrity, stability, and safety of tunnels, ultimately facilitating efficient and secure transportation networks underground.

- Q: How do steel billets contribute to the manufacturing of household appliances?

- The manufacturing of household appliances heavily relies on steel billets, as they serve as the fundamental material for creating various components and structures used in these appliances. To begin with, steel billets are utilized in the production of frames and structures for appliances like refrigerators, washing machines, and dishwashers. The exceptional strength and durability of steel make it an ideal choice for these purposes, ensuring that the appliances can endure constant use and heavy loads. Moreover, steel billets are employed in the manufacturing of both inner and outer panels for household appliances. These panels require a material that possesses strength, resistance to corrosion, and aesthetic appeal. Steel perfectly meets these criteria, providing a sleek and long-lasting surface that can be easily cleaned and maintained. In addition, steel billets are essential for creating various components found within household appliances, including heating elements, motors, and electrical parts. Steel's remarkable thermal conductivity and electrical properties make it a suitable material for these crucial components, guaranteeing efficient operation and reliable performance. Additionally, steel billets contribute significantly to the overall safety of household appliances. Steel is highly resistant to fire, reducing the risk of accidents caused by overheating or electrical malfunctions. Furthermore, its strength and stability play a vital role in preventing structural failures that could lead to accidents or injuries. In summary, the strength, durability, corrosion resistance, and thermal/electrical properties of steel billets make them indispensable in the manufacturing of household appliances. By providing the necessary raw material, steel billets enable the production of robust structures, appealing panels, critical components, and safe appliances that meet the expectations and demands of consumers.

- Q: What are the different types of casting processes used for shaping steel billets?

- There are several types of casting processes used for shaping steel billets. Some of the common ones include continuous casting, ingot casting, and centrifugal casting. Continuous casting involves pouring molten steel into water-cooled molds to create a continuous strand of solidified steel. Ingot casting involves pouring molten steel into individual molds to create solidified ingots. Centrifugal casting utilizes centrifugal force to pour molten steel into a rotating mold, resulting in a cylindrical shape. These casting processes offer different advantages and are used depending on the specific requirements of the steel billet shaping process.

- Q: How is a steel billet made?

- Continuous casting is a common method used to produce steel billets. This process includes several steps that involve the gathering and processing of raw materials, the transformation of these materials into molten pig iron, and the refining of the molten pig iron in either a basic oxygen furnace or an electric arc furnace. In these refining furnaces, impurities are eliminated and alloying elements may be added to achieve specific properties. Once the molten steel is chemically balanced and refined, it is ready for casting. To do this, the steel is poured into a water-cooled copper mold known as a continuous caster. As it flows into the mold, the steel solidifies and takes the shape of a long rectangular or square billet. During the casting process, water is circulated through the mold to cool the steel quickly and aid in solidification. This controlled cooling ensures that the billet has a consistent structure and the desired mechanical properties. After solidification, the billet is cut into predetermined lengths using a torch or a shear. These billets can vary in size and weight depending on their intended use. Once cut, the billets can undergo further processing through rolling, forging, or other shaping methods to create various steel products such as bars, rods, tubes, or structural shapes. In summary, the production of a steel billet involves the transformation of raw materials into molten steel, the refining of the molten steel, and the casting of it into a solid shape using continuous casting. These billets then serve as the starting point for the production of a wide range of steel products used in various industries.

- Q: What is the role of steel billets in the manufacturing of material handling equipment?

- Steel billets play a crucial role in the manufacturing of material handling equipment. These billets are essentially semi-finished steel products that are used as the raw material for various manufacturing processes. In the context of material handling equipment, steel billets are typically used in the fabrication of heavy-duty components such as frames, beams, and brackets. These components need to possess high strength, durability, and resistance to wear and tear in order to withstand the demanding conditions that material handling equipment often operates in. The use of steel billets allows manufacturers to create these components with the necessary mechanical properties. The billets are first heated and then shaped through processes like rolling, forging, or extrusion to produce the desired shape and dimensions. This shaping process ensures that the components have the required strength and structural integrity to handle the weight and stress associated with material handling tasks. Furthermore, steel billets offer excellent weldability, which is crucial in the fabrication of material handling equipment. The ability to weld the components together ensures that the equipment can be assembled securely and efficiently. This is especially important for equipment such as cranes, forklifts, and conveyors, where the safe and efficient movement of heavy loads is paramount. Moreover, steel billets provide a cost-effective solution for manufacturing material handling equipment. Steel is widely available, relatively affordable, and can be recycled, making it a sustainable choice. The versatility of steel billets also allows manufacturers to create components of various shapes and sizes, enabling customization to meet specific requirements. Overall, the role of steel billets in the manufacturing of material handling equipment is crucial. They provide the raw material necessary to create strong, durable, and reliable components that can withstand the demanding conditions of material handling tasks. With their excellent mechanical properties and weldability, steel billets contribute to the safe and efficient operation of material handling equipment.

Send your message to us

Steel billet from China for sale in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16542 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords