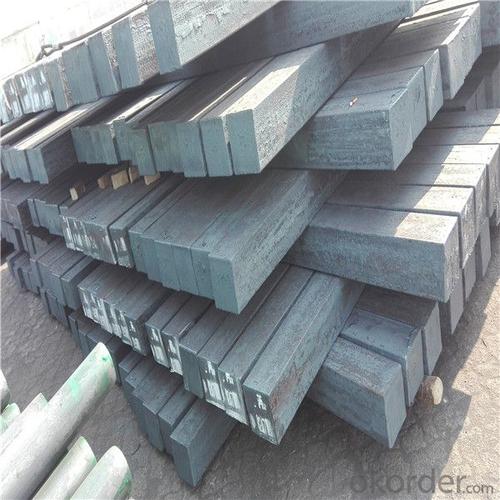

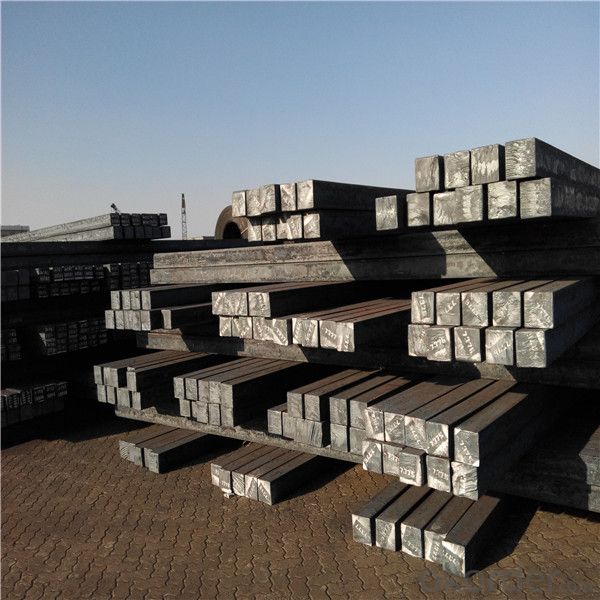

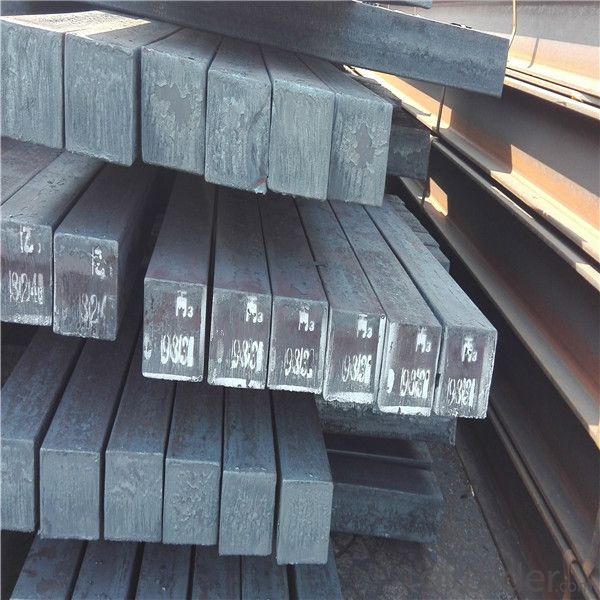

Square steel billets 150*150 from China market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 31842 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the production of automotive chassis?

- Automotive chassis production relies heavily on steel billets, which are integral for creating the necessary components. These billets are cast from molten steel into rectangular or square shapes and then processed further. Initially, the steel billets undergo hot rolling, a procedure that involves heating them to high temperatures and passing them through rollers to shape them accordingly. This elongates the billets and gives them different profiles, such as I-beams or C-channels, which are commonly used in automotive chassis construction. Once the desired shape is achieved, the hot-rolled steel goes through quenching and tempering. This process rapidly cools the steel in a controlled manner, enhancing its strength and durability. The steel is then reheated and slowly cooled to stabilize its microstructure, resulting in improved mechanical properties. Next, the processed steel billets are cut into specific lengths and welded together to create the main structural components of the automotive chassis, including the frame and subframe. These components provide the necessary strength, rigidity, and stability to support the vehicle and endure the various loads and stresses encountered during operation. Steel billets are favored in automotive chassis production due to their excellent strength-to-weight ratio, high tensile strength, and ability to withstand impact and bending forces. These characteristics ensure the safety and stability of the vehicle, as well as provide a solid foundation for other automotive components like suspension systems, engine mounts, and body panels. In summary, steel billets are essential in the production of automotive chassis as they serve as the raw material for creating various structural components. Their strength, durability, and versatility make them the preferred choice in the automotive industry, guaranteeing that vehicles are built to endure the demands of everyday use and offer a safe and reliable driving experience.

- Q: What are the main types of defects found in steel billets?

- The main types of defects found in steel billets include surface defects such as cracks, pits, and scars, internal defects like inclusions, blowholes, and voids, as well as dimensional defects such as improper shape, size, or straightness.

- Q: Can steel billets be used in the production of agricultural equipment?

- Steel billets have the potential to be utilized in the manufacturing process of agricultural equipment. These billets are essentially unfinished products that are typically formed through a continuous casting method. They can undergo further processing to take on various shapes and sizes, which makes them suitable for the production of agricultural machinery like plows, cultivators, harrows, seeders, and other similar farm equipment. The utilization of steel billets in agricultural machinery brings about numerous benefits. Steel is renowned for its robustness, longevity, and resistance to deterioration, making it ideal for heavy-duty applications within the agricultural sector. Moreover, steel is capable of withstanding harsh environmental conditions, ensuring that the machinery remains dependable and functional even in demanding farming environments. Furthermore, steel can be easily shaped and fabricated into different forms, allowing for the customization of agricultural equipment to meet specific requirements. Overall, incorporating steel billets in the manufacturing process of agricultural equipment enhances the efficiency, productivity, and longevity of farming operations.

- Q: What are the common uses of steel billets?

- Steel billets are commonly used in the production of various steel products such as bars, rods, wire, pipes, and structural components. They serve as the raw material for further processing and shaping, making them essential in industries like construction, manufacturing, and infrastructure development.

- Q: How do steel billets contribute to the manufacturing of industrial equipment?

- The production of industrial equipment heavily relies on steel billets, which are essential for the manufacturing process. These semi-finished steel products are created through casting and act as the raw material for a wide range of industrial equipment. A key aspect of steel billets is their versatility, which greatly contributes to the manufacturing of industrial equipment. They possess both malleability and strength, allowing them to be easily shaped and molded into various forms, such as bars, rods, or sheets. This adaptability enables manufacturers to produce durable and reliable components and structures capable of withstanding heavy loads and extreme conditions. Furthermore, steel billets offer an impressive strength-to-weight ratio, making them particularly suitable for applications where reducing weight is crucial without compromising structural integrity. This quality proves beneficial for industrial equipment that requires frequent transportation or movement, as the use of lightweight steel billets optimizes efficiency and minimizes energy consumption. Additionally, steel billets play a significant role in protecting industrial equipment against corrosion and wear. Many industrial environments expose equipment to harsh conditions, including moisture, chemicals, and abrasion. The utilization of steel billets ensures that the equipment remains resistant to these challenges, reducing maintenance and replacement costs while maintaining performance over time. Moreover, steel billets facilitate efficient heat treatment processes during the manufacturing of industrial equipment. Through controlled heating and cooling procedures, manufacturers can enhance the mechanical properties of the steel, such as hardness, toughness, and ductility. This enables the production of equipment capable of withstanding high temperatures, extreme pressures, and dynamic loading conditions, ensuring safety and reliability across various industrial applications. In conclusion, the role of steel billets in the manufacturing of industrial equipment is indispensable. Their versatility, strength-to-weight ratio, corrosion resistance, and facilitation of heat treatment processes contribute to the creation of durable, reliable, and high-performance equipment capable of meeting the demands of diverse industries.

- Q: What are the main factors affecting the magnetic properties of steel billets?

- The main factors affecting the magnetic properties of steel billets are composition, microstructure, and processing conditions. Firstly, the composition of the steel billet plays a significant role in its magnetic properties. The presence of certain alloying elements, such as nickel, cobalt, and manganese, can enhance the magnetic properties of steel. These elements align the magnetic domains within the steel, resulting in increased magnetization and improved magnetic properties. Secondly, the microstructure of the steel billet affects its magnetic properties. The grain size, crystal structure, and presence of defects or impurities can influence the magnetic behavior of the material. Finer grain sizes tend to have better magnetic properties due to improved alignment of the magnetic domains. Additionally, a single-phase crystal structure is generally more magnetic than a multi-phase structure. Lastly, the processing conditions during the production of steel billets can impact their magnetic properties. Factors such as temperature, cooling rate, and mechanical deformation can affect the microstructure and, consequently, the magnetic behavior. For example, rapid cooling can result in a finer grain size and better magnetic properties, while mechanical deformation can induce magnetic anisotropy, making the steel more magnetically oriented along a specific direction. In summary, the magnetic properties of steel billets are mainly influenced by the composition, microstructure, and processing conditions. By controlling these factors, manufacturers can tailor the magnetic properties of steel billets to meet specific requirements for various applications, such as in electrical transformers, motors, or magnetic sensors.

- Q: What are the different types of surface coating methods used for steel billets?

- Steel billets commonly undergo various surface coating methods to improve their durability, corrosion resistance, and overall performance. Some frequently utilized techniques for coating steel billets include: 1. Hot-dip galvanizing: Immersing the steel billets in molten zinc forms a protective layer, ensuring excellent durability and preventing corrosion. 2. Electroplating: Electrochemically depositing a thin layer of metals like zinc, nickel, or chromium onto the surface of the steel billets enhances corrosion resistance and improves aesthetics. 3. Powder coating: Applying a dry powder onto the steel billets' surface and subsequently heating it creates a protective layer. This method offers exceptional durability, chemical resistance, and a wide range of color options. 4. Paint coating: A liquid paint is applied to the steel billets, forming a protective layer that provides corrosion resistance. This technique allows for customization with different colors and finishes. 5. Thermal spray coating: A thermal spray gun is used to spray molten or powdered metals onto the steel billets' surface. This coating provides outstanding wear resistance, corrosion protection, and can be customized with various materials. 6. Anodizing: While primarily used for aluminum billets, anodizing can also be applied to steel. This electrochemical process creates an oxide layer on the steel billets' surface, enhancing corrosion resistance and providing a decorative finish. Each of these coating methods has its own set of advantages and disadvantages, and the selection depends on factors such as the desired protection level, aesthetics, and specific requirements of the steel billets.

- Q: What are the different international trade regulations for steel billets?

- There are several international trade regulations that govern the trade of steel billets. These regulations aim to promote fair trade practices, ensure product quality, and prevent unfair competition. Some of the key regulations for steel billets include: 1. Tariffs and duties: Many countries impose tariffs or import duties on steel billets to protect domestic steel industries. These tariffs can vary significantly between countries and may change periodically. Importers and exporters need to be aware of these tariffs and factor them into their pricing and cost calculations. 2. Anti-dumping measures: Anti-dumping regulations are in place to prevent the sale of steel billets in foreign markets at prices lower than their production cost, which can harm domestic industries. If a country determines that steel billets are being dumped into their market, they may impose anti-dumping duties or other measures to address the issue. 3. Trade agreements and trade barriers: International trade agreements, such as free trade agreements or regional trade blocs, can affect the trade of steel billets. These agreements may reduce or eliminate tariffs and other trade barriers between participating countries, promoting smoother trade flows. Conversely, countries not party to such agreements may face higher trade barriers, making it more challenging to export or import steel billets. 4. Quality and safety standards: Steel billets must meet specific quality and safety standards set by importing countries. These standards may include specifications for dimensions, chemical composition, mechanical properties, and other attributes. Importers and exporters need to ensure their steel billets comply with these standards to avoid rejection or additional inspection upon arrival. 5. Export controls: Some countries impose export controls or restrictions on certain goods, including steel billets, to ensure domestic supply or protect national security interests. These controls can limit the quantity or destination of steel billet exports, requiring exporters to obtain licenses or permits before shipping. 6. Documentation and customs requirements: International trade of steel billets requires proper documentation and adherence to customs procedures. Exporters must provide accurate and complete documentation, including commercial invoices, packing lists, certificates of origin, and other relevant documents. Importers must comply with customs requirements and pay any applicable duties or fees. It is essential for businesses involved in the trade of steel billets to stay informed about these international trade regulations. They should regularly monitor changes in tariffs, anti-dumping measures, trade agreements, and quality standards to ensure compliance and make informed business decisions.

- Q: How are steel billets used in the manufacturing of machine parts?

- Machine parts manufacturing heavily relies on steel billets, which serve as vital raw materials. These billets, solid and semi-finished steel products, are cast into specific shapes and sizes. The utilization of steel billets involves a series of stages. To begin with, the steel billets are heated in a furnace to a specific temperature. This heating process softens the metal, increasing its malleability. Once the desired temperature is reached, the billets are ready for further processing. Subsequently, the heated billets are transferred to a rolling mill, where they undergo hot rolling. During this process, the billets are subjected to pressure from a series of rollers, which shape them into bars, rods, or sheets according to the desired form. The hot rolling process ensures that the steel billets acquire the necessary dimensions and surface finish. Following hot rolling, the shaped steel billets undergo additional processing techniques, such as cutting, forging, or machining, to fabricate machine parts. These parts can encompass gears, shafts, valves, or any other components essential for machinery. The utilization of steel billets in machine parts manufacturing provides several advantages. Firstly, steel billets are renowned for their high strength and durability, making them ideal for producing parts capable of withstanding heavy loads and harsh operating conditions. Additionally, the malleability of steel billets enables the creation of intricate shapes and designs, ensuring the production of complex machine parts. Furthermore, steel billets can be easily customized to meet specific requirements. They can be alloyed with other metals or undergo various heat treatments to enhance properties such as hardness, corrosion resistance, or wear resistance. This versatility of steel billets makes them suitable for a wide range of machine parts across diverse industries. In conclusion, steel billets play a pivotal role in machine parts manufacturing. Through processes like hot rolling, cutting, forging, and machining, steel billets transform into diverse shapes and sizes, yielding durable and high-quality components for machinery. The strength and adaptability of steel billets render them indispensable raw materials in the manufacturing industry.

- Q: What are the different types of steel billet forging machines?

- There are several different types of steel billet forging machines, including mechanical presses, hydraulic presses, screw presses, and hammer forging machines. Each type of machine has its own unique characteristics and capabilities, allowing for the efficient and precise forging of steel billets into desired shapes and sizes.

Send your message to us

Square steel billets 150*150 from China market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 31842 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords