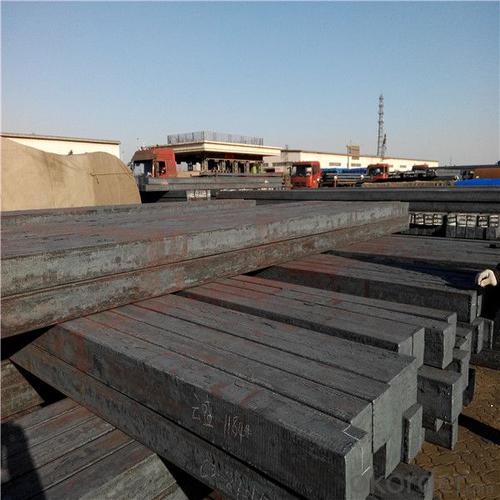

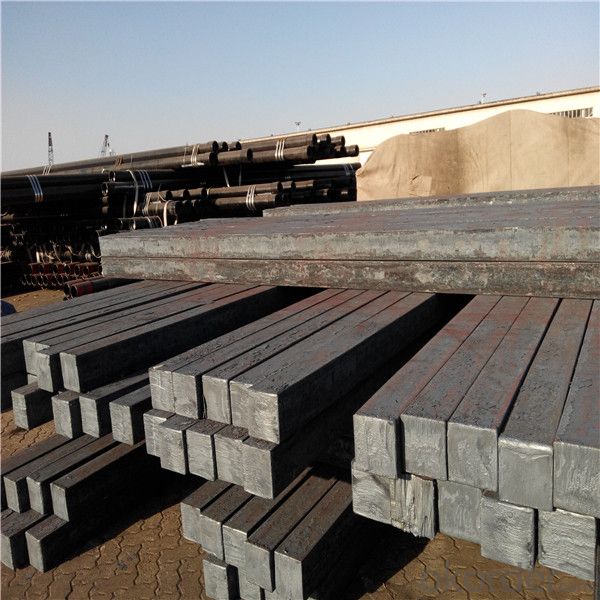

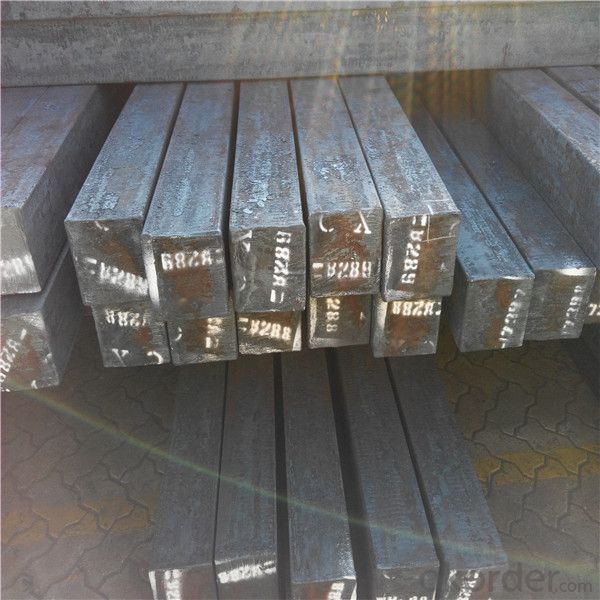

Chrome alloy square steel billet made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Used for the plant, the bridge,shipment building high rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the production of valves and fittings?

- Steel billets are a crucial raw material in the production of valves and fittings. These billets, which are essentially semi-finished steel products, undergo various processes to ultimately form the desired shape and size of valves and fittings. Firstly, steel billets are heated to a specific temperature in a furnace to make them more malleable. This allows for easier shaping and manipulation of the steel during subsequent forming processes. Once heated, the billets are then transferred to a rolling mill where they are passed through multiple rollers to gradually reduce their cross-sectional area and length. This process, known as hot rolling, helps to refine the steel's grain structure and improve its mechanical properties. After hot rolling, the steel billets are often further processed through a method called extrusion. In this process, the heated billet is forced through a die, which imparts the desired shape and dimensions onto the steel. Extrusion is commonly used to produce cylindrical or tubular shapes, which are essential components in valves and fittings. Once the desired shape is achieved, the extruded steel is generally subjected to heat treatment processes such as quenching and tempering to enhance its strength and durability. This helps to ensure that the final valves and fittings can withstand the demanding conditions they will be subjected to during their operational life. Finally, the heat-treated steel is machined and finished to meet the specific requirements of the valves and fittings. This includes processes such as drilling, threading, and surface finishing to achieve the necessary dimensions, threads, and smoothness. In summary, steel billets are transformed into valves and fittings through a series of processes including heating, hot rolling, extrusion, heat treatment, and machining. These processes ensure that the resulting valves and fittings possess the necessary strength, durability, and dimensional accuracy required for their intended applications.

- Q: Are steel billets used in the shipbuilding industry?

- Yes, steel billets are commonly used in the shipbuilding industry. Steel billets are semi-finished steel products that are typically used as raw materials for further processing. In shipbuilding, these billets are typically used to manufacture various structural components, such as plates, beams, and bars that make up the structure of a ship. The high strength and durability of steel make it an ideal material for shipbuilding, as it can withstand the harsh conditions of the marine environment. Additionally, steel billets can be easily shaped and welded, allowing for the construction of complex ship structures. Overall, steel billets play a crucial role in the shipbuilding industry by providing the necessary raw materials for constructing strong and reliable ships.

- Q: What shape is the billet?

- Material standardThickness range: 150-240mm +/-5mm, width range: 880-1530mm +/-20mmLength range: 3700-10000mm +/-500mmCross section size: 64*64; 82*82; 98*98; 124*124; 152*170mm; 120*150; 152*164;Length: 9000mmSection tolerance: square billet: +1.0/-2.0----+3.0/-1.0mm slab: width: +/-2.0MM thickness: +/-3.0MMLength tolerance: +/-200MMDiagonal tolerance of section: 3.5-8.0MMBillet cross section dimension requirements: <1242MM, not allowed; =1242MM, <=2MM, >1242MM, <=3MMBreaking (shear) expansion deformation: <1242MM square billet: no control; slab: <=15MMSurface inclination: no more than 0.1 of the bloomBending length: not more than 10MM per 1MTwist: length <=5M, <=11. Length <=7.5M, <=5.Material 3SP/PS, chemical composition,%:C, Mn, Si, S, P

- Q: How do steel billets contribute to the oil and gas industry?

- Steel billets are essential components in the oil and gas industry, playing a significant role in various applications. These billets are semi-finished metal products that are used as raw materials for manufacturing pipes, valves, fittings, and other equipment required in the extraction, transportation, and refining of oil and gas. One of the primary uses of steel billets in the industry is for the production of seamless pipes. These pipes are crucial for the transportation of oil and gas over long distances, as they provide a secure and reliable means of conveying these valuable resources. Steel billets are heated and then rolled into seamless pipes, which offer excellent strength, durability, and resistance to high-pressure environments. These pipes are utilized in offshore drilling, subsea pipelines, and other critical applications within the oil and gas sector. Moreover, steel billets are also utilized in the manufacturing of various valves and fittings used in oil and gas infrastructure. Valves are crucial for controlling the flow of oil and gas throughout the production and transportation processes. Steel billets are shaped into valve bodies, which are then machined to precise specifications, ensuring proper functionality and reliability. Similarly, fittings, such as couplings, elbows, and tees, are manufactured from steel billets to connect different sections of pipelines and equipment, providing a secure and leak-free system. Furthermore, steel billets contribute to the oil and gas industry by being a primary material for constructing storage tanks and pressure vessels. These tanks are used for the storage of crude oil, natural gas, and various petroleum products. Steel billets are transformed into plates, which are then welded together to form these large-scale storage containers. The inherent strength and corrosion resistance of steel make it an ideal material for such applications, ensuring the safe containment of valuable resources. In summary, steel billets are essential to the oil and gas industry as they are transformed into various components used in the extraction, transportation, and refining processes. From seamless pipes for long-distance transportation to valves, fittings, and storage tanks, steel billets provide the necessary strength, durability, and reliability required in this demanding industry.

- Q: How are steel billets used in the production of power transmission equipment?

- Power transmission equipment relies heavily on steel billets, which are indispensable for their production. Gears, shafts, and couplings, vital components of power transmission equipment, necessitate materials that possess both high strength and durability to endure the forces and stresses involved in transmitting power. Steel billets, categorized as semi-finished steel products, play a pivotal role in meeting these requirements. Primarily, steel billets serve as the raw material for forging or casting processes, enabling the creation of diverse power transmission equipment components. Through forging, billets are subjected to high temperatures and shaped under immense pressure, resulting in a robust and compact material with exceptional mechanical properties. On the other hand, casting involves pouring molten steel into molds to form intricate shapes. In this process, steel billets are melted and cast into molds to fabricate complex components like gears or shafts. Moreover, the composition and quality of steel billets are meticulously controlled to ensure the final product aligns with the specific demands of power transmission equipment. Steel billets are manufactured using various steel grades, each possessing distinct properties such as strength, hardness, and wear resistance. The selection of the appropriate steel grade relies on the particular application and operating conditions of the power transmission equipment. For example, a gear employed in heavy-duty industrial machinery may require a higher strength steel billet compared to a gear used in a smaller-scale application. Additionally, steel billets can undergo further processing, such as heat treatment, to enhance their mechanical properties. Heat treatment processes like quenching and tempering have the potential to bolster the hardness, toughness, and overall performance of the billets. This guarantees that the final power transmission equipment possesses the necessary strength and durability to withstand the challenges associated with power transmission. In conclusion, steel billets play a paramount role in the production of power transmission equipment due to their strength, durability, and flexibility. They act as the raw material for forging or casting processes, facilitating the creation of intricate components. Meticulous selection of steel grade and utilization of heat treatment processes ensure that the final product meets the specific requirements of power transmission equipment, solidifying the integral role of steel billets in the manufacturing process.

- Q: How are steel billets used in the manufacturing of food processing equipment?

- Steel billets are used in the manufacturing of food processing equipment as they serve as the primary raw material for shaping and forming various components such as frames, supports, blades, and cutting tools. These billets are heated, rolled, and machined into desired shapes and sizes to create durable and robust equipment that can withstand the demanding conditions of food processing operations while ensuring hygiene, safety, and efficiency.

- Q: How are steel billets used in the production of crankshafts?

- Steel billets are used in the production of crankshafts as they serve as the raw material that is shaped and machined to form the main body of the crankshaft. These billets are heated, forged, and then machined to create the precise shape and dimensions required for the crankshaft. This process ensures the strength, durability, and performance of the crankshaft in engines.

- Q: What are the different types of defects that can occur during steel billet production?

- There are several types of defects that can occur during steel billet production. Some common defects include surface cracks, internal voids or inclusions, segregation, surface roughness, and dimensional deviations. Surface cracks can occur due to improper cooling or handling, while internal voids or inclusions can be caused by impurities in the raw materials. Segregation refers to uneven distribution of elements within the billet, leading to inconsistent properties. Surface roughness can result from inadequate surface preparation or poor rolling conditions. Dimensional deviations can occur due to improper alignment or adjustment of the equipment.

- Q: What are the different types of surface coating methods used for steel billets?

- There are several types of surface coating methods used for steel billets, including galvanizing, electroplating, powder coating, and painting. Galvanizing involves applying a layer of zinc to the surface of the billets to provide corrosion resistance. Electroplating uses an electrical current to deposit a thin layer of metal onto the steel surface, enhancing its appearance and protecting it from corrosion. Powder coating involves applying a dry powder to the billets, which is then heated to form a protective layer. Painting is another common method, where a liquid paint is applied to the billets to provide both protection and aesthetic appeal.

- Q: Does anyone know how much it costs to refine a ton of steel? What are the expenses involved?

- Electricity, water, wages, raw materials, raw materials loss, charges, oxygen, according to their own circumstances, as well as freight and other expenses,

Send your message to us

Chrome alloy square steel billet made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords