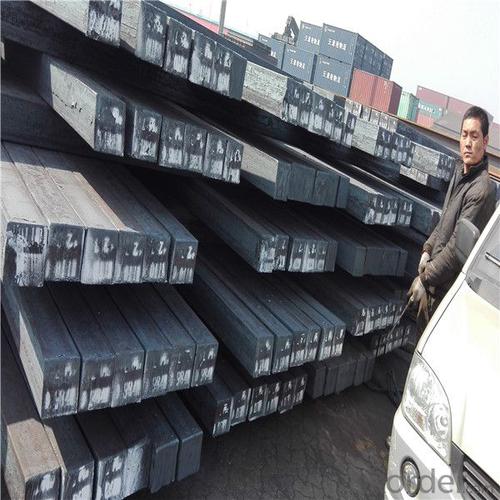

Steel billet price from China steel factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the

support foundation pile manufacturing.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

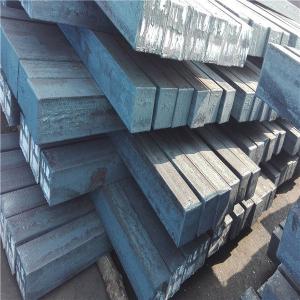

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different quality standards for steel billets?

- Steel billets undergo assessment based on various quality standards to determine their overall quality and suitability for different purposes. Notable quality standards include: 1. ASTM A615/A615M: This standard outlines the criteria for deformed and plain carbon-steel bars used in concrete reinforcement. It encompasses billets utilized in the production of reinforcing bars, focusing on their specific mechanical properties and dimensional tolerances. 2. ASTM A706/A706M: This standard specifies the requirements for low-alloy steel utilized in the production of reinforcing bars. It details the chemical composition, mechanical properties, and dimensional tolerances of the billets. 3. EN 10025-2: A European standard that stipulates the requirements for non-alloy structural steels. It covers billets used in the production of various structural elements, including beams, columns, and plates. The standard defines the chemical composition, mechanical properties, and technical delivery conditions of the steel billets. 4. JIS G3112: A Japanese industrial standard that addresses steel bars employed in concrete reinforcement. It outlines the chemical composition, mechanical properties, and tolerances for billets used in the production of reinforcing bars. 5. GB/T 699: A Chinese standard that establishes the quality requirements for carbon structural steels. It defines the chemical composition, mechanical properties, and technical delivery conditions of steel billets used in diverse structural applications. These quality standards guarantee that steel billets meet specific criteria concerning strength, durability, and dimensional accuracy. By adhering to these standards, one ensures that the steel billets are of superior quality and suitable for their intended use in construction, manufacturing, and reinforcement applications.

- Q: How are steel billets used in the manufacturing of packaging materials?

- Steel billets are used in the manufacturing of packaging materials by being rolled into thin sheets to create metal containers or cans. These billets are first heated and then passed through a series of rolling machines to achieve the desired thickness. These sheets are further processed and shaped to form different types of packaging materials such as cans, boxes, or containers, which provide durability and strength to protect and preserve various products during transportation and storage.

- Q: How are steel billets transported and stored?

- Steel billets are typically transported and stored in a careful and systematic manner to ensure their quality and safety. When it comes to transportation, steel billets are usually moved using trucks or railcars. Trucks are commonly used for short-distance transportation within a steel mill or between different facilities, while railcars are employed for longer distances, including intercity or even international transport. During transportation, steel billets are loaded onto the trucks or railcars using cranes or forklifts. It is crucial to secure the billets properly to prevent any movement or damage during transit. Straps, chains, or other securing methods are used to keep the billets in place and ensure their stability. Once the steel billets reach their destination, they are unloaded using similar lifting equipment. It is important to handle the billets with care during the unloading process to avoid any scratches or dents that could compromise their structural integrity. Regarding storage, steel billets are typically kept in designated areas called billet yards or billet storage facilities. These areas are designed to accommodate the size and weight of the billets and provide easy access for loading and unloading operations. Steel billets are often stored in stacks or piles, with each billet being carefully positioned to maintain stability and prevent any potential accidents. The billets may be organized based on various criteria, such as size, grade, or production date, to facilitate their retrieval when needed. To protect the billets from environmental factors, such as humidity or corrosion, they are often covered with protective coatings or stored in enclosed areas with controlled climate conditions. Additionally, regular inspections and maintenance are carried out to ensure the quality and integrity of the stored billets. Overall, proper transportation and storage procedures are essential to safeguard the steel billets and maintain their quality until they are ready for further processing or use in various industries.

- Q: Can steel billets be used for structural purposes?

- Structural purposes can indeed be served by steel billets. These particular steel products are considered semi-finished and are typically shaped through hot-rolling or forging techniques to create various structural components such as beams, columns, and more. Their utilization in construction and engineering projects is widespread due to their ability to provide strength, durability, and the capability to bear heavy loads. Before being incorporated into the construction process, these billets are often further processed and shaped according to specific design requirements. The construction industry heavily relies on steel billets for the construction of buildings, bridges, highways, and other infrastructure projects due to their exceptional mechanical properties and high strength-to-weight ratio. Moreover, their suitability for various structural applications is enhanced by their ease of welding.

- Q: What are the challenges faced in steel billet manufacturing?

- Some of the challenges faced in steel billet manufacturing include achieving consistent quality, maintaining efficiency in production processes, managing energy consumption, ensuring the safety of workers, and addressing environmental concerns. Additionally, market fluctuations and competition can also pose challenges in terms of pricing and demand.

- Q: What is the typical density of a steel billet?

- The typical density of a steel billet depends on the specific type of steel being used. However, in general, the density of a steel billet ranges from 7.75 to 8.05 grams per cubic centimeter (g/cm³). This density can vary slightly depending on the composition and quality of the steel. It is important to note that the density of a steel billet can also be affected by any impurities or contaminants present in the material.

- Q: Are steel billets used in the production of construction equipment?

- Yes, steel billets are commonly used in the production of construction equipment. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes and sizes. These billets serve as the raw material for manufacturing construction equipment components, such as beams, plates, rods, and structural parts. The use of steel billets in construction equipment ensures the durability, strength, and reliability of the final product, making it suitable for heavy-duty applications in the construction industry.

- Q: How are steel billets coated or painted?

- Steel billets can be coated or painted through several methods. One common technique is hot-dip galvanizing, where the billets are immersed in a bath of molten zinc. This process forms a protective zinc coating on the surface of the steel, preventing corrosion. Another method is electroplating, which involves the deposition of a thin layer of metal, such as zinc or nickel, onto the billets using an electric current. Additionally, steel billets can be painted using various coating systems, such as powder coating or liquid paint, to provide a decorative finish or additional protection against rust and environmental factors.

- Q: Are steel billets recyclable?

- Yes, steel billets are recyclable. Steel is one of the most recycled materials in the world, and the process of recycling steel billets is well-established and highly efficient. When steel billets reach the end of their useful life, they can be melted down and reused to produce new steel products. This recycling process helps to conserve natural resources, reduce energy consumption, and minimize environmental impact. Additionally, recycling steel billets also helps to reduce the amount of waste sent to landfills and contributes to the circular economy by promoting the sustainable use of resources.

- Q: What is the role of steel billets in the manufacturing of material handling equipment?

- Material handling equipment manufacturing relies heavily on steel billets, which are essential semi-finished steel products used as raw materials for various manufacturing processes. When it comes to material handling equipment, steel billets find their primary application in fabricating heavy-duty components like frames, beams, and brackets. These components must possess exceptional strength, durability, and resistance to wear and tear to endure the demanding conditions in which material handling equipment operates. Steel billets enable manufacturers to create these components with the necessary mechanical properties. Initially, the billets are heated and then shaped through processes such as rolling, forging, or extrusion to achieve the desired shape and dimensions. This shaping process ensures that the components have the required strength and structural integrity to handle the weight and stress associated with material handling tasks. In addition, steel billets offer excellent weldability, which is crucial for fabricating material handling equipment. The ability to securely and efficiently weld the components together ensures the safe and efficient movement of heavy loads, particularly in equipment like cranes, forklifts, and conveyors. Furthermore, steel billets provide a cost-effective solution for manufacturing material handling equipment. Steel is readily available, relatively affordable, and can be recycled, making it a sustainable choice. The versatility of steel billets also allows manufacturers to create components of various shapes and sizes, enabling customization to meet specific requirements. In conclusion, steel billets play a vital role in the manufacturing of material handling equipment. They provide the necessary raw material to create strong, durable, and reliable components that can withstand the demanding conditions of material handling tasks. With their excellent mechanical properties and weldability, steel billets contribute to the safe and efficient operation of material handling equipment.

Send your message to us

Steel billet price from China steel factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords