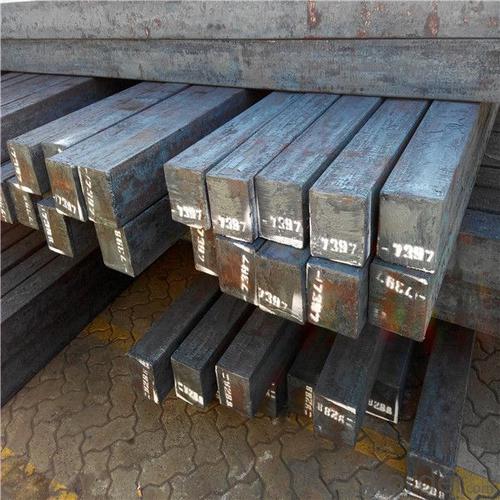

Steel Billet Low Price in high quality hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and

molding.

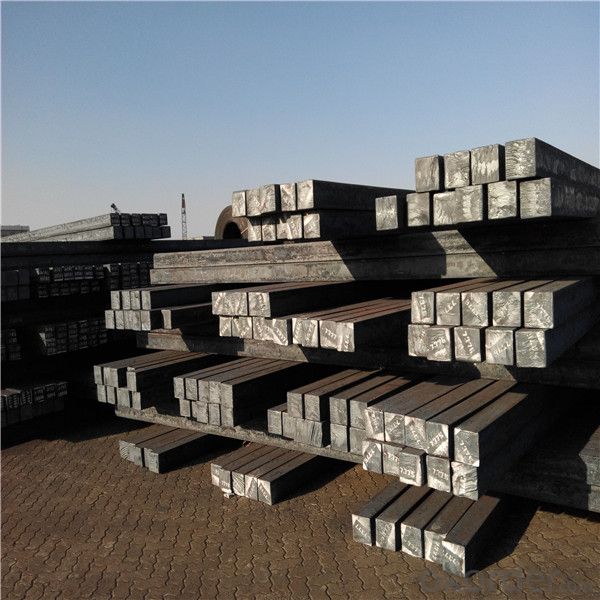

Used for the plant, the bridge,shipment building high rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

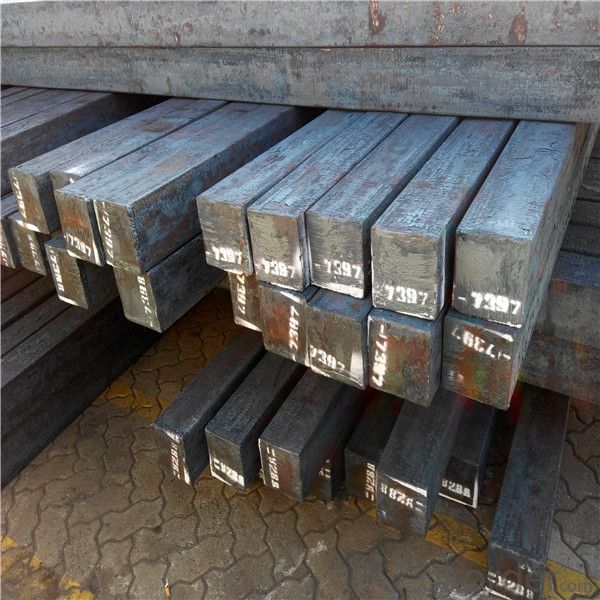

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the common defects in steel billets during continuous casting?

- Steel billets during continuous casting can experience various common defects. These defects include surface cracks, central segregation, inclusion defects, internal cracks, surface and subsurface defects, and pipe defects. Surface cracks are cracks that appear on the billet's outer surface. They can occur due to excessive cooling or improper mold lubrication. These cracks can weaken the structural integrity of the billet and potentially cause breakage during subsequent processing. Central segregation is a defect that arises from an uneven distribution of elements within the billet. This uneven distribution leads to variations in composition across the billet's cross-section. As a result, the billet may possess inconsistent mechanical properties, making it unsuitable for certain applications. Inclusion defects occur when non-metallic particles or impurities become trapped within the billet during casting. These particles can originate from the refractory lining, mold powder, or the steelmaking process itself. Inclusion defects weaken the material and diminish its overall quality. Internal cracks are cracks that develop within the billet's body. Thermal stresses or improper cooling are often the culprits behind these cracks. Detecting internal cracks visually is challenging, and they can compromise the structural integrity of the billet. Surface and subsurface defects encompass various issues such as surface depressions, oscillation marks, and hot tears. Surface depressions arise from excessive mold oscillation or poor mold conditions. Oscillation marks result from non-uniform mold oscillation, leading to uneven cooling and inconsistent billet dimensions. Hot tears occur when the billet contracts unevenly during solidification, resulting in cracks on the surface or subsurface. Pipe defects are hollow cavities that form within the billet during solidification. Shrinkage is the main cause of these cavities, and they can weaken the material. If these pipes propagate to the surface, they can cause breakage during subsequent processing. Overall, these defects pose significant challenges in producing high-quality steel billets. Continuous improvement in casting techniques, process control, and quality assurance measures are crucial in minimizing these defects and ensuring defect-free billet production.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets are a crucial component in infrastructure development as they serve as the raw material for manufacturing various steel products used in construction. These billets are used to produce reinforcement bars, beams, columns, and other structural elements that provide strength and stability to buildings, bridges, roads, and other infrastructure projects. By providing a strong and durable foundation, steel billets contribute significantly to the overall safety and longevity of infrastructure, promoting sustainable development and economic growth.

- Q: How do steel billets contribute to the water treatment industry?

- Steel billets are used in the water treatment industry to manufacture various components such as pipes, valves, and fittings. These components are vital for the construction and maintenance of water treatment infrastructure. Steel billets provide the necessary strength, durability, and corrosion resistance needed to withstand harsh conditions and chemicals involved in water treatment processes. Thus, steel billets play a crucial role in ensuring the efficiency and longevity of water treatment systems.

- Q: What are the different types of non-destructive testing methods used for steel billets?

- Steel billets undergo various non-destructive testing methods to ensure their quality and integrity without causing any damage or alteration. Commonly used techniques include: 1. Ultrasonic Testing (UT): High-frequency sound waves are utilized to detect internal defects like cracks, voids, and inclusions that may affect the billet's performance. 2. Magnetic Particle Testing (MPT): Magnetic fields and particles are employed to identify surface and near-surface defects such as cracks and seams that may be invisible to the naked eye. 3. Eddy Current Testing (ECT): By measuring changes in electrical conductivity and magnetic fields, ECT can detect surface and near-surface defects like cracks and corrosion. 4. Visual Inspection: This basic method involves a thorough visual examination to identify visible defects such as surface cracks, dents, or irregularities. 5. Penetrant Testing (PT): A liquid or fluorescent dye is applied to the billet's surface, seeping into any surface defects. After removing excess dye and applying a developer, defects like surface cracks and porosity become visible. 6. Radiographic Testing (RT): Using X-rays or gamma rays, RT penetrates the billets to produce images revealing internal defects like cracks, inclusions, and voids. Employing a combination of these techniques, manufacturers ensure the safety and performance of steel billets by identifying and rectifying potential defects or inconsistencies.

- Q: What is the weight of a standard steel billet?

- The weight of a standard steel billet can vary depending on its dimensions and specific alloy composition. However, on average, a standard steel billet weighs around 1,000 to 1,500 kilograms or 2,204 to 3,307 pounds. It is important to note that different industries and regions may have their own standard sizes and weight ranges for steel billets.

- Q: How are steel billets used in the production of agricultural harvesting equipment?

- Steel billets are a crucial component in the production of agricultural harvesting equipment due to their strength, durability, and versatility. These billets are typically used to create the main structural framework of various types of agricultural machinery, such as combine harvesters, threshers, and balers. One of the primary applications of steel billets in the production of agricultural harvesting equipment is in the construction of the machine's frame. The frame serves as the backbone of the equipment, providing stability and support for all other components. Steel billets are ideal for this purpose as they have high tensile strength, allowing them to withstand the heavy loads and stresses encountered during harvesting operations. Additionally, steel billets are also utilized to manufacture various critical components of agricultural machinery. For example, they are often used to produce cutting blades, augers, and conveyors, which are essential for efficiently harvesting and processing crops. Steel's excellent wear resistance and toughness make it an ideal material for these components, as they need to withstand the abrasion and impact caused by contact with crops and other debris. Furthermore, steel billets are commonly employed in the manufacturing of hoppers, chutes, and other storage and transportation systems within agricultural harvesting equipment. These components are responsible for collecting, sorting, and transferring harvested crops, and therefore need to be robust and reliable. Steel billets provide the necessary strength and rigidity to ensure the efficient handling and movement of agricultural products. In summary, steel billets play a vital role in the production of agricultural harvesting equipment. Their strength, durability, and versatility make them indispensable for creating the main structural framework, critical components, and storage systems of these machines. By utilizing steel billets, manufacturers can ensure the production of reliable and efficient agricultural machinery that can withstand the demanding conditions of harvesting operations.

- Q: What are the different types of steel billet surface treatment defects?

- There are several types of steel billet surface treatment defects that can occur during the manufacturing process. These defects can affect the quality and appearance of the steel billets, and it is important to identify and address them to ensure the overall performance of the final product. 1. Scale: Scale is a common defect that occurs when the steel billet is exposed to high temperatures during the manufacturing process. It appears as a layer of oxide on the surface of the billet, which can affect the adhesion of coatings or paints. 2. Inclusions: Inclusions are non-metallic particles or impurities that can be present on the surface of the steel billet. These inclusions can be caused by various factors, such as inadequate cleaning or improper handling during the manufacturing process. They can negatively impact the mechanical properties of the steel and reduce its overall performance. 3. Decarburization: Decarburization is a defect that occurs when the surface layer of the steel billet loses its carbon content due to exposure to high temperatures or a lack of protective atmosphere. This can lead to reduced hardness and strength in the affected area. 4. Pitting: Pitting is a localized defect that appears as small cavities or pits on the surface of the steel billet. It can be caused by the presence of impurities or by exposure to corrosive environments. Pitting can compromise the structural integrity of the billet and make it more susceptible to corrosion. 5. Surface cracks: Cracks can occur on the surface of the steel billet due to various factors, such as thermal stress, improper handling, or inadequate cooling. Surface cracks can weaken the billet and increase the risk of failure during subsequent processing or use. 6. Surface roughness: Surface roughness refers to an uneven or irregular surface texture on the steel billet. It can be caused by factors such as improper machining, inadequate cleaning, or the presence of scale or inclusions. Surface roughness can affect the appearance of the billet and may also impact its performance in certain applications. Overall, it is crucial to identify and address these surface treatment defects to ensure the quality and reliability of steel billets. Proper manufacturing processes, including adequate cleaning, protective atmospheres, and appropriate handling, can help minimize the occurrence of these defects and ensure the optimal performance of the final product.

- Q: How do steel billets contribute to the manufacturing of medical devices?

- Steel billets contribute to the manufacturing of medical devices in various ways. Firstly, steel billets serve as the raw material for the production of medical devices. These billets are used as a starting point in the manufacturing process, where they are heated and shaped into the desired form using techniques like forging, casting, or rolling. The use of steel billets in medical device manufacturing offers several advantages. Steel is known for its strength, durability, and corrosion resistance, making it an ideal material for the production of medical devices that need to withstand rigorous use and maintain their integrity over time. Additionally, steel offers excellent biocompatibility, meaning it is well-tolerated by the human body, reducing the risk of adverse reactions or complications when the medical devices are implanted or used in surgical procedures. Moreover, steel billets can be easily machined and formed into complex shapes, allowing manufacturers to create intricate medical devices such as orthopedic implants, surgical instruments, or prosthetic components. Steel's versatility and malleability enable the production of devices with precise dimensions and fine details, ensuring optimal functionality and performance. Furthermore, steel billets contribute to the manufacturing of medical devices by providing a cost-effective solution. Steel is widely available and relatively affordable compared to other materials used in the medical industry, making it an attractive choice for manufacturers. The ability to produce medical devices from steel billets at a reasonable cost contributes to the accessibility and affordability of healthcare worldwide. In conclusion, steel billets play a crucial role in the manufacturing of medical devices. They provide a strong, durable, and biocompatible material that can be easily shaped and machined into complex forms. Steel's properties contribute to the production of high-quality medical devices that are capable of withstanding demanding applications while ensuring patient safety and cost-effectiveness.

- Q: After processing to the color coating board, is there a fare increase of 1000?The price of galvanized coil is about +350 per ton of cold-rolled steel at present What about the cost of billet to cold rolling?What is the final cost of making the color coated sheet? How do you figure that?

- I think that the cost of steel billet plus manual consumption plus electricity and other costs divided by the finished product is greater than the cost per ton

- Q: How do steel billets contribute to the sustainability of construction projects?

- Steel billets contribute to the sustainability of construction projects in several ways. First, steel is an incredibly durable and long-lasting material. Steel billets are the raw form of steel that can be used to manufacture various construction components such as beams, columns, and reinforcement bars. These components provide structural integrity and strength to buildings, ensuring their longevity. By using steel billets, construction projects can be built to withstand extreme weather conditions and natural disasters, reducing the need for frequent repairs or replacements. This durability directly contributes to the sustainability of construction projects by reducing waste and conserving resources over time. Second, steel is a highly recyclable material. Steel billets can be recycled and reused indefinitely without losing their quality or performance. Recycling steel reduces the energy consumption, greenhouse gas emissions, and waste associated with the production of new steel. By incorporating recycled steel billets into construction projects, the demand for virgin steel can be reduced, thereby conserving natural resources and minimizing environmental impact. Additionally, the use of steel billets in construction allows for efficient and versatile designs. Steel is known for its high strength-to-weight ratio, allowing for lighter and slimmer structural elements that require fewer materials. This not only reduces the overall weight of the building, but also decreases the amount of concrete and other construction materials required. As a result, less energy is consumed in the production and transportation of these materials, leading to a more sustainable construction process. Furthermore, steel is resistant to pests, such as termites and fungi, which can cause significant damage to buildings. By using steel billets, construction projects can avoid the use of chemical treatments typically required to protect wooden structures, reducing the environmental impact of pest control measures. In conclusion, steel billets contribute to the sustainability of construction projects through their durability, recyclability, efficient design possibilities, and resistance to pests. By incorporating steel into construction, buildings can be built to last, reduce waste, conserve resources, and minimize environmental impact.

Send your message to us

Steel Billet Low Price in high quality hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords