Lamp Reflector Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Our company specializes in manufacturing metal forming equipments with over 10 years in business.

All of them sell well in home and abroad, and are widely used in building materials, chemicals, metallurgical industry, electric power, coal, food, machinery, etc. We have established good reputation of quality and after-sale service.

1.Type: Ceiling grid or drywall partition component

2.Thickness:0.4-1.2mm, size:42*25, 52*25, 72*25, 75*25, 100*34.5

3.Length: 2800mm, 3000mm, 3200mm

4.Light weight, high strength

5.Package:10pcs per bundle with plastic strip or iron wire

6.MOQ: 10 Tons, negotiable

7.Delivery time: T/T,

Feature and advantage

1)Rust proof

2)Corrosio-resistance

3)Multi-roll production technology

4)Fireproof, anti-seismic

5)Environmental friendly, Pls Be Assured Use

6)Easy installation, precisely dimensioned

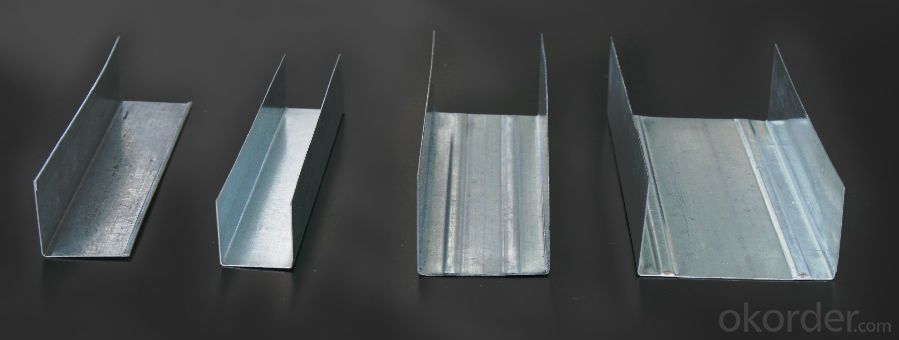

3.Image

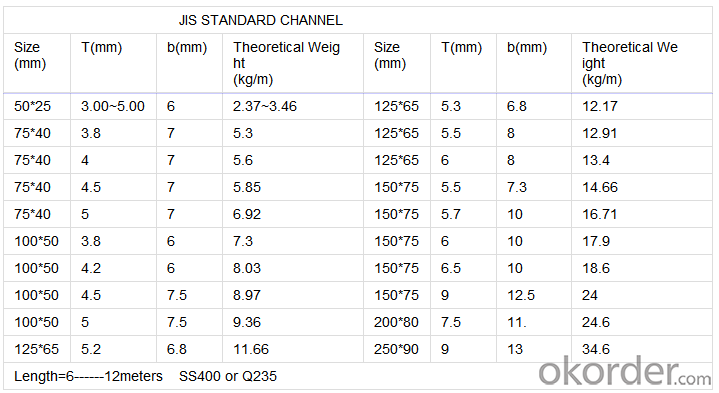

4.Detailed Specification

5.FAQ

Dry wall system install

1.To fix the ceiling track and the floor track to the clear ceiling and the clear floor with the shoot-nails.

2.Install the metal stud to the ceiling track and the floor track, and use the rivets to fix them in accordance with the design space.

3.The gypsum boards should be installed to the frame with the tapping screw, when the whole frame is formed .

4.One-layer gypsum board is used , the space between two gypsum plaster boards should be staggered. And the double-gypsum board is used the space between two gypsum plaster boards should also be staggered.

5.Joint putty process the final decoration can be done.

- Q:Ceiling light steel keel 50/60 in 60 on behalf of what

- Specifications model ah main keel 50 is 50 × 15 × 1.2 60 is 60 × 27 × 1.2

- Q:Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Different regions, the material is more than 20 yuan a square, construction costs 20 yuan a square,

- Q:Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- When the hanging length of more than 1.5m should be set anti-support, reverse support is in the case of normal boom, from the lower end of the boom oblique ceiling installation to connect a rod, rod to have a certain stiffness, and the boom to form a Solid triangular. To prevent the ceiling in the air pressure when the upward deformation, the formation of dome, causing damage to the ceiling. The number of anti-support should be set according to the construction plan.

- Q:Home ceiling with green steel skeleton or wooden frame

- Of course it is steel dragon skeleton!

- Q:Light steel keel ceiling which brand is better

- You can go to the forum to consult the other owners to see everyone's views

- Q:Tectonic levels and practices of light steel keel

- First find the ceiling of the horizontal line, and then installed in the roof on the big expansion screws. Under the boom, the distance from the boom do not exceed 80mm installation hook, and then on the 38 keel hanging with the installation of the vice keel we generally do 40mm grid, gypsum board specifications are 120mm / 3000mm. Gypsum board installation to stay, 5mm gap. Then there is adhesive powder leveling. And then stick to the bandage, in the putty putty, brush paint.

- Q:Home woodworking ceiling, with wood keel and light steel keel which cost-effective higher ah?

- To be honest, light steel keel cost-effective. This is also part of the progress of the times.

- Q:What is a man ceiling, what is not a man ceiling?

- My idea is that the master name suggests, you can master, ask the high point of the tune, the keel to meet the requirements of the Master, and now sell the keel is not on the Master and Master, keel easy to repair, Learn from everyone

- Q:Light steel keel gypsum board ceiling artificial materials about how much money a square meter

- Light steel keel ceiling material costs about 40. Keel 'gypsum board GB and non-standard price gap, depending on your choice. Labor costs flat about 35, modeling top 50-60 a square, depending on the specific complexity.

- Q:Light steel keel ceiling crack repair several times is always cracked Guiqiu expert guidance

- The top child is wrong! You put the top a little bit aside!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lamp Reflector Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords