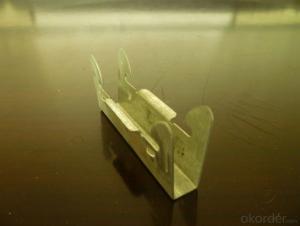

Australian Style Gypsum False Ceiling Accessories with Ceiling Profile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

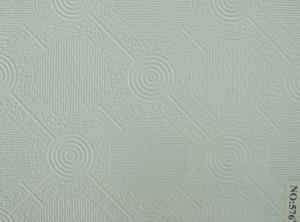

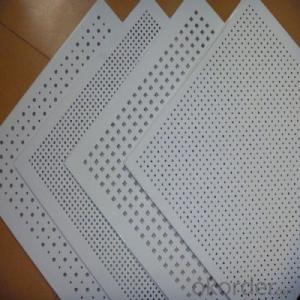

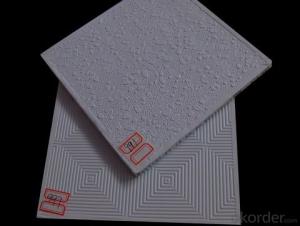

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

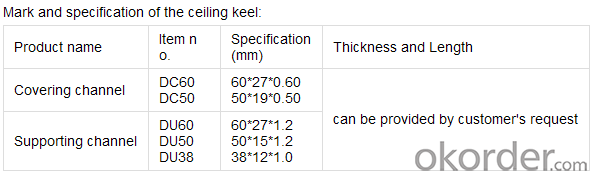

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: What is the general ceiling of indoor ceiling?

- Now a lot of aluminum buckle board, very cheap, the effect is also good

- Q: Divided u-type light steel keel in the ceiling spacing of less than 2 meters, 2.5 meters or less, according to the large keel count spacing, or by the small keel count spacing.

- Do not understand your "spacing within 2m", "2.5m or less" What does it mean. Light steel keel ceiling is a standard, the main keel and the main keel spacing between the maximum can not exceed 1.2m, if more than this distance, and should try to do reinforcement treatment;

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- Light steel keel: Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on. ? Light steel keel 38 refers to the material used as keel is light steel, its cross-section and the channel is similar to the width of 38 mm series, the height of 12 mm, the thickness is not a certain value, generally depending on the force from 0.5 mm To between 1.0 mm. 38 * 12 * 0.5 38 * 12 * 0.6 38 * 12 * 0.7 38 * 12 * 0.8 38 * 12 * 1.0

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q: Light steel keel ceiling cracks how to deal with

- There are many reasons for the cracking of the roof, and the repair of cracks caused by different causes is not the same. Therefore, after the cracks, the first should be how the cracks are generated, to identify the problem of pipe fittings, and then develop a rest plan, should not blindly construction. Otherwise it may fall into a crack, make up the vicious cycle of the process. There are three main reasons and treatment methods: 1, the surface of the paint surface cracking repair If only the ceiling film to generate linear, multi-angle or irregular cracks, then the problem is not very serious. The reason may be due to a brushing too thick or dry re-coated, the substrate is too loose or rough, primer and paint is not matched and so on. Repair measures: to eliminate the affected film; to ensure that the film is not a very thick construction; to ensure that the front paint dry after re-coating; if necessary, with the appropriate primer to seal the substrate; for roughness of the substrate, The use of good flexibility of the product; substrate temperature below 5 ℃, not construction latex paint; primer and finish to match. 2, the temperature changes caused by the ceiling cracking If it is due to temperature changes caused by cracking, generally appear in the surface, will not affect the safety of the ceiling, the surface can be processed about. 1, the gap is not: If the surface gap is not large, it is recommended in the gap posted a layer of kraft paper, and then brush the surface coating. 2, the gap is wide: If the surface gap is wide, then it is best to cut out a piece of gypsum board, polished into the appropriate shape, fill in the gap, and then brush the finish paint. 3, improper construction caused by the ceiling cracking if it is because the ceiling frame, gypsum board finishes, etc. ...

- Q: Light steel keel ceiling crack repair several times is always cracked Guiqiu expert guidance

- You can first in the cracks where there are a few screws, in the back to do so that is not your big move, to rework from the hope that you can help you,

- Q: Light steel keel gypsum board ceiling hanging cut short can be connected to you

- One can pick up, buy a place to have a set of reed, about three centimeters. If you hang the tendons shorter than five centimeters recommended more short points up and down regulation.

- Q: The difference between light steel keel ceiling and macadam ceiling

- Do you mean light steel keel ceiling and wooden keel ceiling? Who used the big board to do the shelf ah ... ... Light steel keel Ye Hao, wood keel Ye Hao, after playing the shelf, have to use the big core board to do modeling, and then covered with a layer of gypsum board, directly directly with gypsum board to do modeling

- Q: Light steel keel how to do secondary ceiling

- From top to bottom to do, the highest point to do a good job, and then do the following level, and the wood is interspersed with the construction is good, if not let it only play two rows of hanging bars

Send your message to us

Australian Style Gypsum False Ceiling Accessories with Ceiling Profile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords