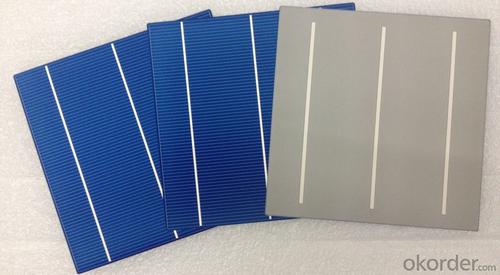

Monocrystalline Solar Silicon Wafer - High Quality A Grade Cell Polyrystalline 5V 17.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: What is the expected cost reduction for solar silicon wafers in the future?

- It is difficult to provide an exact figure for the expected cost reduction of solar silicon wafers in the future as it depends on various factors such as technological advancements, economies of scale, and market dynamics. However, based on current trends, it is anticipated that the cost of solar silicon wafers will continue to decline gradually, making solar energy more affordable and accessible.

- Q: How are solar silicon wafers protected from physical damage?

- Solar silicon wafers are protected from physical damage through a combination of encapsulation and packaging techniques. The wafers are typically coated with a thin layer of protective material, such as glass or polymer, to shield them from external forces, moisture, and temperature variations. Additionally, they are often laminated between layers of transparent materials, such as tempered glass or polymer films, to provide further protection against impacts, scratches, and environmental degradation. This encapsulation process ensures that the delicate silicon wafers remain intact and functional throughout their lifespan.

- Q: What is the average lifespan of a solar silicon wafer?

- The average lifespan of a solar silicon wafer can vary depending on various factors such as the quality of the wafer, the manufacturing process, and the conditions in which it is used. However, on average, a solar silicon wafer can last anywhere from 25 to 30 years.

- Q: How are solar silicon wafers protected from chemical damage during manufacturing?

- Solar silicon wafers are protected from chemical damage during manufacturing through various methods. One common technique is the application of passivation layers, such as silicon nitride or silicon dioxide, which act as protective coatings. These layers prevent chemical reactions between the silicon and other substances, ensuring the wafers remain undamaged. Additionally, the manufacturing process may involve using cleanrooms with controlled environments to minimize the presence of potentially harmful chemicals. Quality control measures, including regular inspections and testing, are also implemented to ensure the wafers' protection from chemical damage throughout the manufacturing process.

- Q: How are solar silicon wafers packaged for transportation and installation?

- Solar silicon wafers are typically packaged for transportation and installation in protective materials such as foam or anti-static packaging. These packages are designed to prevent damage to the delicate wafers during handling and transit. Additionally, the wafers are often placed in specially designed containers or trays that provide further protection and secure their position. This packaging ensures that the wafers reach their destination safely and can be easily installed without any harm or contamination.

- Q: How long does a solar silicon wafer typically last?

- A solar silicon wafer typically lasts for several decades, with an average lifespan ranging from 25 to 30 years.

- Q: What is the typical payback period for a solar silicon wafer installation?

- The typical payback period for a solar silicon wafer installation varies depending on several factors such as the initial investment, energy production, local electricity rates, and any available incentives or subsidies. On average, it ranges from 5 to 10 years, but this can be shorter or longer based on specific circumstances.

- Q: What is the lifespan of a solar silicon wafer?

- The lifespan of a solar silicon wafer can vary, but typically it is expected to last for around 25 to 30 years.

- Q: How long do solar silicon wafers last in a solar panel?

- Solar silicon wafers can last for several decades in a solar panel, typically around 25 to 30 years.

- Q: Are solar silicon wafers affected by vibrations or shocks?

- Yes, solar silicon wafers can be affected by vibrations or shocks. Vibrations or shocks can cause microcracks or damage to the delicate structure of the wafers, which can impact their performance and efficiency in converting sunlight into electricity. Therefore, it is important to handle and transport solar silicon wafers with care to minimize any potential damage.

Send your message to us

Monocrystalline Solar Silicon Wafer - High Quality A Grade Cell Polyrystalline 5V 17.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords