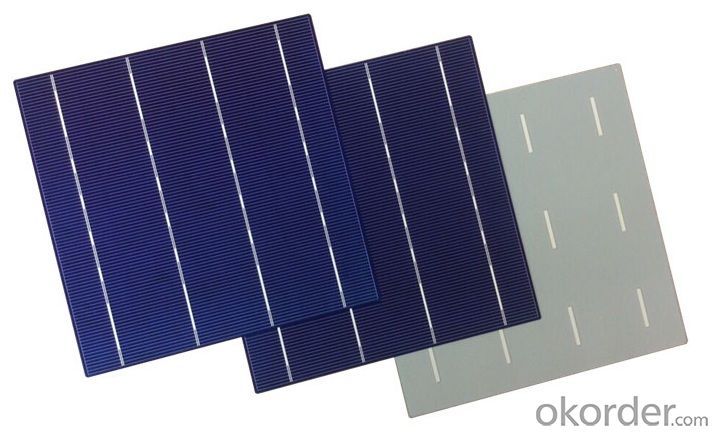

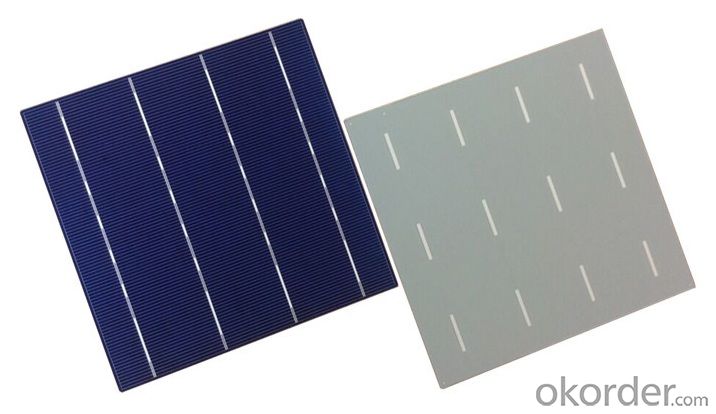

156*156mm 3BB Mono-crystalline Silicon Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

156*156mm 3BB Mono-crystalline Silicon Solar Cell

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Dimension | 156mm X 156 mm ±0.5mm |

Wafer Thickness | 200um ±30um |

Front(-) | Four 1.1mm wide bus bars(silver) with distance 39mm, Acid texturized surface with blue silicon nitride AR coating. |

Back(+) | 2.4mm wide silver/aluminum soldering pads, aluminum back surface field. |

Product Show

Package

Typical package for one carton contains 1,200 cells. The cells are sealed in cell box every 100 pcs.

Gross weight per unit carton shall be around 16.4kg.

- Q: What is the role of passivation in solar silicon wafers?

- The role of passivation in solar silicon wafers is to reduce the surface recombination of electrons and holes, which can significantly improve the efficiency and performance of solar cells. Passivation helps create a protective layer on the surface of the silicon wafer, minimizing defects and preventing the recombination of charge carriers. This leads to a higher open-circuit voltage, increased current generation, and enhanced overall solar cell efficiency.

- Q: What is the global production capacity of solar silicon wafers?

- The global production capacity of solar silicon wafers is estimated to be around 120 GW (gigawatts) per year.

- Q: What can be used to adjust its viscosity

- If you are slicing, don't adjust it yourself. The final formulation of the mortar with the proportion of mixing time, there is a relationship. The proportion of the appropriate density viscosity enough to find manufacturers

- Q: Do solar silicon wafers require regular maintenance?

- Solar silicon wafers do not require regular maintenance as they are designed to be highly durable and require minimal upkeep. However, occasional cleaning to remove dirt, dust, or debris can help optimize their performance and efficiency.

- Q: Can solar silicon wafers be used in underwater applications?

- Yes, solar silicon wafers can be used in underwater applications. They are designed to be waterproof and can withstand the effects of being submerged in water. However, proper sealing and protection measures need to be in place to prevent any damage or corrosion to the wafers.

- Q: How is the wafer appearance caused? The performance of the chip half white, a class of black! Seek help!

- You first check the silicon wafer TTV, as well as doping concentration distribution.

- Q: What is the role of solar silicon wafers in reducing air pollution?

- Solar silicon wafers play a crucial role in reducing air pollution by serving as the key component in solar panels, which generate clean and renewable energy. By harnessing sunlight and converting it into electricity, solar panels powered by silicon wafers eliminate the need for fossil fuel-based power generation, thereby reducing harmful emissions that contribute to air pollution.

- Q: What is the typical efficiency range of solar silicon wafers?

- The typical efficiency range of solar silicon wafers is between 15% to 22%.

- Q: What is the effect of power output on the performance of a solar silicon wafer?

- The power output of a solar silicon wafer directly impacts its performance. Higher power output indicates that the wafer can generate more electricity, leading to increased efficiency and effectiveness in converting sunlight into usable energy. A higher power output allows for greater electricity generation and better overall performance of the solar silicon wafer.

- Q: How is a degradation rate measured in a solar silicon wafer?

- The degradation rate in a solar silicon wafer is typically measured by monitoring the decrease in the efficiency or power output of the solar cell over a specific period of time. This can be done by regularly measuring the current-voltage characteristics or the maximum power point of the solar cell and comparing it to the initial performance. The degradation rate is then calculated by dividing the decrease in efficiency or power output by the duration of monitoring.

Send your message to us

156*156mm 3BB Mono-crystalline Silicon Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords