Solar Silicon Wafer for Sale - High Quality A Grade Monocrystalline 5V 19.2% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

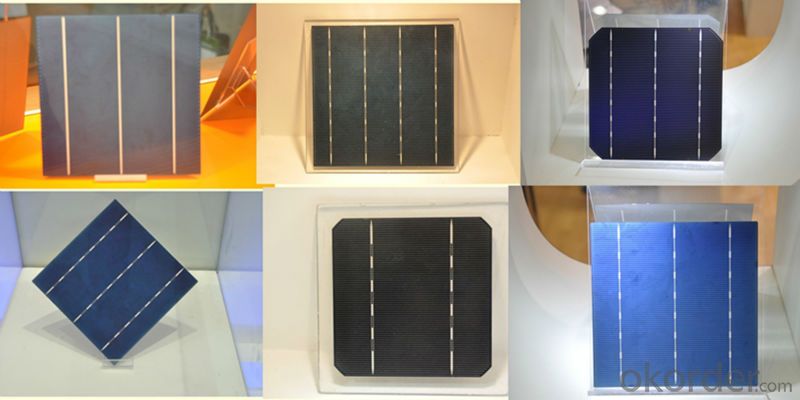

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: What is a silicon wafer for unidirectional and bidirectional cutting? What is the difference between the two?

- One way and two way cutting of silicon wafer is the two way to cut silicon ingot by using solar energy cutting wire.When slicing machine uses solar cutting line to cut silicon ingot,

- Q: How do solar silicon wafers perform in coastal environments?

- Solar silicon wafers generally perform well in coastal environments due to their resistance to corrosion and moisture. However, exposure to saltwater and high humidity levels can potentially cause some degradation over time. Therefore, it is crucial to use high-quality materials and proper maintenance practices to ensure optimal performance and longevity in such environments.

- Q: How is a mounting structure attached to a solar silicon wafer?

- A mounting structure is typically attached to a solar silicon wafer using a combination of adhesive materials and mechanical fasteners. The adhesive material, such as a specialized bonding agent or thermal conductive paste, helps to securely bond the mounting structure to the wafer's surface. Additionally, mechanical fasteners like screws or clips are used to provide additional stability and ensure a strong attachment between the mounting structure and the silicon wafer.

- Q: How is a power output measured in a solar silicon wafer?

- The power output of a solar silicon wafer is typically measured by connecting it to a load resistance and measuring the voltage and current generated by the wafer. The power output is then calculated by multiplying the voltage and current values.

- Q: In the silicon surface cleaning, there is a final step, the silicon chip into the 4% concentration of HF solution soak for five minutes, to hydrogen passivation treatment, and then rinse with deionized water after nitrogen drying,What is the role and mechanism of this hydrogen passivation?

- 0.5 ~ 1min in order to achieve the effect of removing the damage layer, at this timeCorrosion rate can reach 6 to 10um/min.In the polishing process to remove the damage layer on the basis to try to reduce, to prevent corrosion of the wafer was too thin.

- Q: What is the purpose of surface texturing in solar silicon wafers?

- The purpose of surface texturing in solar silicon wafers is to increase the efficiency of solar cells by reducing reflection and maximizing light absorption.

- Q: How are solar silicon wafers coated to prevent reflection losses?

- Solar silicon wafers are coated with an antireflection (AR) coating to minimize reflection losses. This coating, usually made of a thin layer of silicon nitride or titanium dioxide, is applied to the surface of the wafers using various deposition techniques like chemical vapor deposition or sputtering. The AR coating works by altering the refractive index of the surface, allowing more light to pass through the wafer instead of being reflected. This significantly improves the efficiency of solar cells by maximizing the amount of sunlight absorbed.

- Q: Can solar silicon wafers be used in hybrid solar systems?

- Yes, solar silicon wafers can be used in hybrid solar systems. Hybrid solar systems combine different types of renewable energy sources, such as solar and wind, to generate electricity. Solar silicon wafers can be used to capture sunlight and convert it into electrical energy in these hybrid systems, making them an essential component for solar power generation.

- Q: How does the efficiency of a solar silicon wafer change with snow cover?

- The efficiency of a solar silicon wafer decreases with snow cover. Snow acts as an insulating layer, preventing sunlight from reaching the wafer and reducing its ability to convert solar energy into electricity. Additionally, snow can cause shading and blockage of sunlight, further decreasing the efficiency of the solar panel.

- Q: How long does a solar silicon wafer typically last?

- A solar silicon wafer typically has a lifespan of around 25 to 30 years.

Send your message to us

Solar Silicon Wafer for Sale - High Quality A Grade Monocrystalline 5V 19.2% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords