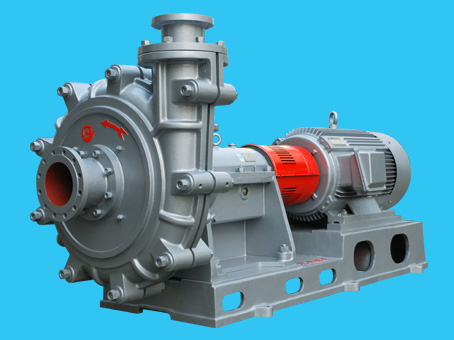

Horizontal Centrifugal Dredge Pump for Dredger

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gasoline gravel pump(ISO9001)

1. Specification

Size: 25mm-450mm

Capacity: max. 3400m3/h

Head: max. 120m

Particle size: max. 260m

2. Material: metal A05, A07, A33, A49 etc

3. Features:

1. Horizontal, cantilevered, centrifugal, single stage slurry pump

2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

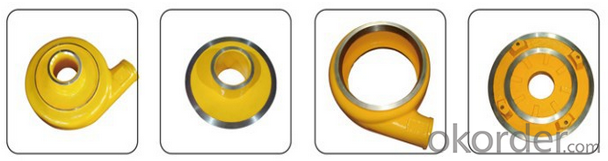

3. Wear resistant and anti-abrasion wet parts: A05, A07, A33, A49 and rubber etc. They are completely interchangeable with each other

4. Easily replaceable liners, Liners are bolted to the casing.

5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

6 Discharge direction can be positioned at intervals of 360 degrees.

7. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

4. Widely application:

They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

5. FAQ:

1 Do you have self-priming pumps?

Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

2 Is it really necessary to fit a bleed valve for the boxes?

It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

3 If I increase the power of the motor, must I also increase the power of the inverter?

You must select the size of converter that allows maximum absorption of the electric motor.

- Q: I did change water pump before but not on wv beetle?

- refer to the repair manual for a guide or visit a shop for help and pay, before you start breaking stuff.

- Q: Ok, so I have a 1997 3.8 liter ford mustang. I was driving home from work the other day, when temp gauge started to go up. I brought it to mechanic, and he said it was a bad water pump, due to bad antifreeze. So I am getting a new pump, and an antifreeze flush. My question is that since it overheated, will there be any damage to the engine? The temperature gauge never hit the red, and smoke never came out. I had to drive it for approx 15-20 miles when it started to overheat, and the temp gauge was bouncing from hot to normal.

- Overheating your engine is never good , but are you certain it was actually overheated or just a loose wire, faulty thermostat or other giving erratic readings.. If the Engine did not SMELL hot, if the engine performance did not change, if it did not overheat to the extreme...and quickly, it was probably NOT the water pump. Too, it probably did not damage the engine if it was overheated only to the degree that you say. I would wonder about the water pump scenario. Is it possible that you were in extended stop and go traffic in hot weather, and/or your radiator fluid was low and basically getting air in the system.? I hope your mechanic is competent and honest, and the problem was as he said. Usually there is NO Question in the symptoms that the Engine is overheated (regardless of gauge reading). The OIL would get very thin and HOT as well. Just wondering. Good luck.. P.S. I just read Avatar Country Boy's response after I submitted mine. He has some good advice too. I would add that if the engine ever overheats and loses water (or needs water) DONT EVER POUR WATER INTO A HOT OVERHEATED ENGINE !!!!! If you got the radiator cap off in the first place without getting scalded or WORSE, if you try to add water it WILL essentially EXPLODE back in your face as it hits super heated cooling system parts, and most likely crack your engine block, and/or warp your engine heads...serious engine damage. Instead, let it cool completely Again...Good luck..

- Q: ive been doing repair work on an old 86 jeep cherokee and when i let it idle there is a water leak, me and my dad came to the conclusion there was something wrong with the water pump. i cant find the manual and i dont even know what im looking for, so where would i find the water pump and how would i go about replacing it?

- For 2.5L 4.0L Engines Some vehicles use a serpentine drive belt and have a reverse rotating water pump coupled with a viscous fan drive assembly. The components are identified by the words REVERSE stamped on the cover of the viscous drive and on the inner side of the fan. The word REV is also cast into the body of the water pump. 1. Disconnect the negative battery cable. 2. Drain the cooling system. 3. Disconnect the hoses at the pump. 4. Remove the drive belts. 5. Remove the power steering pump bracket. 6. Remove the fan and shroud. 7. If equipped, remove the idler pulley to gain clearance for pump removal. 8. Unbolt and remove the pump. To install: 9. Clean the mating surfaces thoroughly. 10. Using a new gasket, install the pump and tighten the bolts to 13 ft. lbs. (18 Nm). 11. If removed, install the idler pulley. 12. Reconnect the hoses at the pump and install accessory drive belt. 13. Install the power steering pump bracket. Install the fan and shroud. 14. Adjust the belt tension and fill the cooling system to the correct level. 15. Operate the engine with the heater control valve in the HEAT position until the thermostat opens to purge air from the system. Check coolant level and fill as required.

- Q: Not sure of the year model but think it is a 1991 to 1995 Jayco 2500FS bumper pull trailer. I bought it to put on a deer lease. One of the previous owners had taken out the water tank which I plan on replacing. I can't find the water pump to see if I need to replace it as well. Also, if you know about how the pump knows when to kick on i.e. pressure switch, push button or what. I know I could take it to have repairs done but enjoy the diy thing. I am in the process of finding out the exact year model as well. Thanks!

- having had many travel trailers the water pump is usually in a cabinet or under a bed or couch with a lot of plastic water lines near where you screw the water hose into the side of the trailer. and they are usually a preset psi from the factory so that is usually nothing to have to worry about and most have an on off switch located in the traier by the kitchen sink.And if the hot water heater is no good look into a tankless water heater it will save you money in the long run but initially you have to have a vent installed up through the roof away from a roof air vent. Another suggestion everytime you move a travel trailer they get the crap pounded out of them and someone needs to go up on the roof with a ladder and/or a plank that goes across the width so there is no weight standing on a roof to make dents or pop seams. Use some plastic stuff like plasticote available at wal mart after you move the trailer and set it up go up and make sure to double coat any of the seams that need it. I crank the heat up inside the trailer and do a double coat the heat rising will put a skin on the plasticote in a few hours instead of 12 or more. and the double coat gets any cracks missed the first time around. After that check it once a year if the trailer stays there.

- Q: A total of three units, usually starting two units. After jumping the gate, it was like this. I haven't paid attention before. Is it a turn around?

- Only trip is not to the frequency converter settings or phase sequence change, if not moved the settings and wiring, most of the reason is the original reversal, you also know that inverter turnover also has water.Check analog positive and negative polarity, inverter settings, and if there is no problem, change the phase sequence.

- Q: My 93 Ford t-bird over heats and i really don't know what could be the problem, the radiator is working fine, and also the fan and the thermostat, i don't think is a head gasket because the oil looks alright with no contamination and there is no steam coming from the exhaust im beginning to suspect the water pump but the weep hole is not leaking. So does a water pump MUST leak from the weep hole if it is bad, or it could be bad and not leak? thanks in advance...

- My husband says: If it has a clutch fan, the clutch could be bad; the impleller in the water pump could be bad or broke and to check and make sure your belt is not slipping. Hope this gives you some ideas!

- Q: Fire hydrant and fire pump adapter difference

- Fire hydrant is out of water, the water pump is water supply to the pipe network

- Q: I will be replacing my timing belt soon. The dealer is suggesting that I also replace the water pump. Is that really necessary? When do water pumps normally go out?

- The labor involved in replacing a timing belt will normally cover the installation of a water pump as well. The reason the dealer is recommending the water pump replacement at this time is that the labor involved in changing the timing belt makes it much more cost effective for you to do it at this time. Even though your water pump is working great right now, if you need to replace it in the future, the labor cost will be enormous and close to the cost of replacing your timing belt alone.

- Q: when i drove my truck after about 15 minutes i was parked and let my truck idle afetr about a minute of idling my truck stalled and when i turned it back of it was squeeking and made some noises for about ten seconds and then stopped. I noticed that the pully on my fan coming from the water pump was wobbling. my tempuratue was still normal what could cause this i am suspecting taht the bearings in my water pump went?

- Ram Water Pump

- Q: I have a bad water pump on my golf gti.Engine is 2.0L. I just would like to know how hard is it to do it myself. And also is there some special tools that I need.How much time usually takes to get this done? Thank you

- This Site Might Help You. RE: 96 vw golf gti water pump? I have a bad water pump on my golf gti.Engine is 2.0L. I just would like to know how hard is it to do it myself. And also is there some special tools that I need.How much time usually takes to get this done? Thank you

Send your message to us

Horizontal Centrifugal Dredge Pump for Dredger

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords