High Strength Composite Materials AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High strength composite materails AR Glassfiber roving

AR glassfiber is one kind of concrete fiber used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Alkali-resistant(AR) fiberglass is the base material to make Fiberglass Reinforced Cement (GRC), which has been widely used in building industry as board, corrugated proofing sheet, division panel, internal and external insulation panel, decorative panel, dust panel, cable box, granary, channels drainage and garden furniture, artistic sculpture, etc.

Products Features and Advantages

1) Excellent chopped performance and dispersion.

2) Fast and complete wet-out.

3) Low static, no fuzz.

4) Easy roll-out and air release.

5) High mechanical strength.

Technical Data of high strength composite materials Ar glass fiber roving:

PRODUCT NAME | AR- FIBERGLASS CHOPPED STRAND | |||

TEST CRITERION | JC/T572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZRO2CONTENT | % | ≥16.5 | 16.7 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.1 | MEASURE UP |

TENSILEBREAKING STRENGTH | N/TEX | ≥0.25 | 0.3 | MEASURE UP |

CHOPPED LENGTH | MM | 12±1 | 12 | MEASURE UP |

LINEAR DENSITY | TEX | 98±8 | 99 | MEASURE UP |

COMBUSTIBLE MATTER CONTENT | % | 0.8-2.0 | 1.48 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T572-2002 | |||

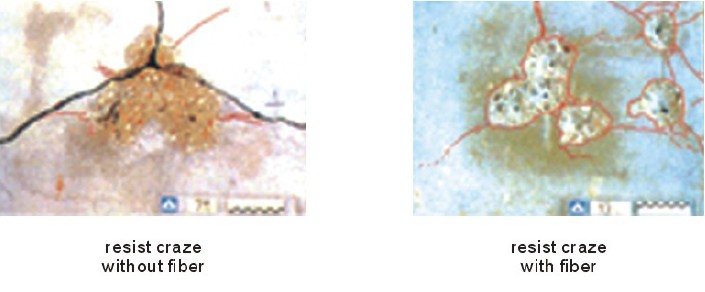

Crack Test:

Packing Style

Each bobbin is 18±1kgs and wrapped by a PVC shrink bag. If required, each bobbin could be packed into a suitable cardboard box.

Each pallet contains 3 or 4 layers, and each layer contains 16 bobbins(4x4). The bobbins in the pallet could be singly piled or be connected as start to end by air spliced or by manual knots.

The whole pallets of bobbins are wrapped with cardboard boxes, packed on the pallet with packing straps and shrink film or with multi-layers of shrink film only.

Storage

This product should be stocked in dry and cool places. The best condition is with temperature between 15 and 35°C, with a relative humidity between 30%-70%. Please keep the product in its original packing before using, avoid moisture.

- Q: my brother wants to know

- cook limestone dust in a kiln to about 2000 degrees = cement

- Q: My basement shower is basically just a cement slab with a drain and fiberglass walls. What's a rough ballpark cost estimate to tear out the cement shower and replace it with a modern glass stall and/or a tile shower?

- By cement slab you refer to the concrete basement floor with a drain in it? Nothing to tear out. A contractor will install a shower pan. Either custom made or a prefab pan and tie into the existing drain. If you want to relocate the shower then he will jack hammer up the slab and run the drain. Save money by having the shower in the same place. For just the shower pan and walls framed, covered with backer board, tile tie into existing hot and cold water supply figure about $4000. If you want to use custom materials like granite and limestone tiles add $1000. Also plan to install an exhaust fan for the steam. If you can be happy with a prefab fiberglass surround it will be half the cost.

- Q: asbestos cement pipe laying procedure?

- AWWA Products Work Practices for Asbestos–Cement Pipe Following the work practices demonstrated in this practical handbook when installing or maintaining asbestos–cement pipe can help limit the release of airborne asbestos fibers—a critical concern. This reference summarizes the OSHA Asbestos Construction Standard and presents recommended work practices developed through experience, study, and field testing. Chapter headings cover shipping, receiving, handling, storage, and assembly; unacceptable work practices; and housekeeping and waste disposal considerations. Essential reading for engineers, managers, and crews alike. Edition: 1995, Softbound, 17 pp. ISBN 0-89867-795-5; Catalog Number 20406. Waternet? Keywords: ASBESTOS CEMENT PIPE Your Price: $ 27.00

- Q: We have an odd shaped living room and the way we have it arranged our couch is sitting in front of the woodstove. It has not been a problem since it has been warm out and we have not been using the stove, but now that fall weather is here we are getting to the point that we are going to have to use it. Our couch sits about 2 feet in front of the stove with the back of the couch facing the stove, its enough room for a person to walk between the couch and stove without touching the stove. I need to know if we can attach a piece of cement board that has ceramic tile on it to the back of our couch to make it safe from getting too hot and causing a fire. Thanks.

- To answer your question, yes, it would be okay to install a cement particle board to the back of your sofa, to provide a barrier between the stove and the sofa. If you choose to go with this option, purchase the ones with higher fire resistance and install the wall backing from the bottom of the couch, to a height high enough to protect people's heads. But. if there is enough space, it would be better to move the couch further from the stove instead. In fact, if you can move some stuff around, it would be much better to shape your furniture like a U, with the open end facing the stove. Just as you would fix it around a fireplace. Because it isn't just the couch you need to protect, it is also the people sitting on it. Flying embers could scorch hair and clothing as well. And if you have small kids, regardless of what you tell them, they will once in a while forget and will pass through the space between the stove and the couch. With a U-shape, there is a better chance that they will pass between furniture, as opposed to between furniture and stove.

- Q: Ferro-cement was the quot;inquot; material to make a boat hull from, and my father was quite taken with the idea behind it. Time and my father have passed, and I am wondering if it is still a viable building material. thank you for your responses.

- If made by a professional, the concrete hull has lots of advantages over its FRP cousin. The concrete gets harder as time goes on. The first one made in the 1860's is still afloat. Cement does not blister or delaminate. The weight can be a read advantage when sailing in choppy seas as it will plow through waves that will stop a lighter vessel. If one should encounter a situation that would hole a FRP vessel, the ferro will cave in like an eggshell. Kick it back in shape, slap some fresh cement on it and off you go. Down side is dealing with marinas. They think that you will come flying into your slip and destroy the dock. As long as you are aware of your extra weight and adjust your maneuvers there should be no problems.

- Q: and yes i have asked that, does any whitening strips or anything break down the cement

- I had a permanent retainer for almost ten years. The retainer itself had come out and all that I had left was the cement. I went to my dentist and within five minutes it was gone. Very simple. But nothing else works. Sorry, but go see your dentist.

- Q: design criteria for cement concrete

- The only criteria for designing with cement or concert is ideas and creativity. You can use it with forms or bender board to make a unique shaped pathways. You can make great home planter boxes. You can pour it into rubber mold's and make all kinds of shapes for your garden or for the interior of your home. Making different size spears are fun and if you make them yourself they are a lot cheaper this way. You can make stepping stones and add stones and leaf impression to add a great design. You can color it with products they sell at Home Depot, Lowes or any good paint store. Once you get started a ton of more idea's will come to you. It really is a fun medium to work with and with last for years. Life long artist...

- Q: Okay, I have some 4quot;PVC to 2quot;PVC reducer, a 4quot; PVC tank/endcap, and a ball valve. It is going to be under a lot of pressure (70-100PSI), this is my first time bonding PVC so what should i do in steps? I heard PVC Primer then Cement it together. Anything else?

- I agree with Corky.... primer, then cement (don't be shy with it), then as you put the two parts together twist 1/4 to 1/2 turn until they are completely together.... And by the way standard PVC is schedule 40 and the pressure rating is well over 100psi... as long as there are no temperature extremes. Good luck with the project.

- Q: What is the best thing to write in wet cement?

- This cement is now dry. or There is a dead body under here LOL Cheers from Australia

- Q: This year, steel, concrete, sand, stone and other building materials prices how, compared with last year is high or low? As long as probably, do not need too much can also,

- According to the international market conditions, especially in the European market, the recent rupiah on the euro exchange rate continued to fall, short-term rebound may be, and its European steel market prices continue to rise, the above view the price of steel prices may rise

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Strength Composite Materials AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords