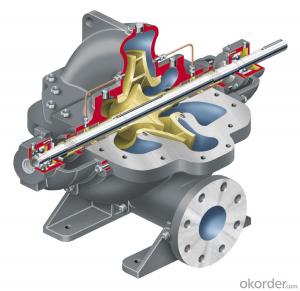

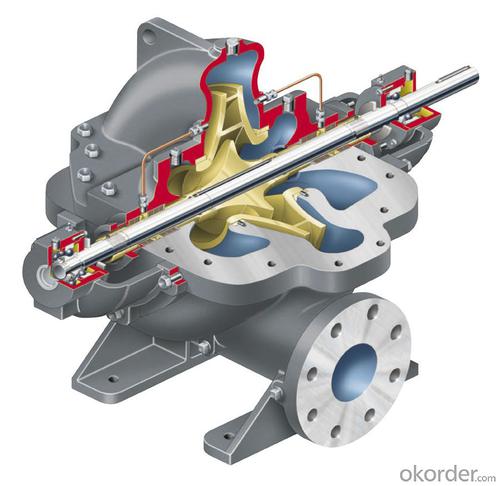

Double Suction Split Case Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of Double Suction Split Case Centrifugal Pump

Tpye SH, XS Split Case Pump/Double suction pump is new type of single stage double suction split case centrifugal pump with high pefformance. They are widely used in delivering liquids to the water plant, circulation water system of airconditioner, pipe net syetem of supplying heated water, construction, drainage

Pumping station, power station, industrial water supply system, ship industry, mine and etc. Type SH,

XS split case pump is advanced products developed from type SH. S. SA. SLA. SAP pumps.

Technical Parameter of Double Suction Split Case Centrifugal Pump

Speed: 990, 1480 and 2960 r/min

Voltage: 380, 6K/10KV

Inlet and Outlet: 150~600mm

Flow range: 68~3975m3/h

Head range: 6~180m

Fuel: Diesel

Engine: DEUTZ engine, water cooled

Advantage of Double Suction Split Case Centrifugal Pump

The efficiency of XS pumps are 2%~3% higher than the same type pumps due to adopting advanced Hydraulic model and thus minimum the operating costs.

2. The NPSH of type XS pumps are 1-3 meters lower than the same type split pumps due to using Advanced hydraulic model and advanced manufacturing technique and thus minimize the foundation costs And extendling the using life.

3. Type XS pumps are suitable for any site working condition due to using SKF NSK bearing and other Parts chosen by the customers and thus minimize the maintenance costs.

MAINTENANCE ADVANTAGE:

1. It is very easy and simple to replace the mechanical seal due to usine container type machaniacl seal.

2. It is rapid easy to assembly and dismout the rotor parts due to using elastic ripess assembling.

3. It is unnecessary to make adjustment when assembling

Application of Double Suction Split Case Centrifugal Pump

XS series Split Case Pump is widely used for water plant, irrigation, drainage pumping station, power station, water circulation of air-conditioning, industrial water supply system, fire system and shipping industry as well as for the general purpose in the oil refining industry.

FAQ

Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

- Q: I have a 2005 Impala and it has been acting funny. Some morning the heat takes about 20 minutes to start working. The air conditoner has not came on once. The gage also takes awhile to start working and when it does it goes pass the halfway mark.I even notice when im sitting at a red light, i can feel the engine shaking a little. I have a appt to get it check and put on the machine tomorrow. I just want to go there with an idea of what the problem could be. Could this be a thermostat or water pump problem???? Help?

- Sounds like the thermostat is sticking,

- Q: Does it take more power to pump water with a 1 /12 hp bg motor/pump than one that is a spare pump/motor running dry,not connected to the system? I am trying to figure out how long it will run with an power inverter during a power failure.

- need the model of pump then i can see how meany watts it uses and tell you how long it will run on a inverter and i also would need the battery cca or if it is a upc back up unit. and they will use a small amount more when they are moving water due to head pressure and friction in the pump and pipe. get me more info and we can figure it out.

- Q: I recently took my 2002 Pontiac Grand Prix in for an oil change, and was told that my water pump has burst. I knew something happened the previous night because all of a sudden my car was overheating and when I opened the hood there was water everywhere, Anyways I am currently a single mom, working temp jobs while I look for something permanent. I can not afford the 350.00 to get it fixed. If I continue to drive the car am I looking at serious damage, He showed me how to fill the water tank (or whatever) so that the car will not be empty, But he says I need to get it fixed soon

- This Site Might Help You. RE: How serious is a broken water pump on a car? I recently took my 2002 Pontiac Grand Prix in for an oil change, and was told that my water pump has burst. I knew something happened the previous night because all of a sudden my car was overheating and when I opened the hood there was water everywhere, Anyways I am currently a single mom, working...

- Q: I found a small submersible water pump for pond decorations or birdbaths in my garage. It's about the size of three decks of cards stacked on top of each other. Would there be any harm/benefit of putting this into a 55 gal fw community tank?

- No it should be no problem , but run it in the water before you put in the aquarium ..To clean out the pump..

- Q: How do I tell the difference between a long and a short water pump? I have a Chevy 350 V8, a crate motor the same size is going in very soon. How do I tell which one I have so that I can get the correct brackets, accessories, etc.?

- The short water pump body measure about 3 1/8, while the long pump measures about 4 3/4. That's measured from where the pump bolts to the block to the outside part of the casting. Not including where the shaft is. If you're looking straight down over the motor and it has a short pump, then the front of the timing chain cover and the rear of the pump are almost on the same line. If it's a long water pump, then looking down there would be about a 7/8 space where you can stick your finger. But don't do that, you could hurt yourself. :-) Hope this helps.

- Q: Multi storey residential buildings also need to set up pressurized water pump room, direct water supply can not be?

- The tap water supply pressure is enough, so there is no need to pressurize.

- Q: I keep having to add water to. Doesn't do anything when it's sitting up. But after you drive it straight for about 25 minutes. Time to add some more water. I figure it's the water pump. It's not leaking anywhere so it has to be a failing water pump. Oil still looks good, no smoking. AC and heater blows fine. Just runs hot after a while. I need another opinion. Its the 4 cylinder also. And yes it does be steaming. Tired of having to add water everyday.

- The water pump seal will go bad if it isn't already because you are adding plain water to the cooling system! Antifreeze has a rust inhibitor and a lubricant in it and if you don't have the correct strength mix the inside of the block rusts and then the heater core and the radiator get plugged up resulting in hundreds of dollars in repairs. The water pump if leaking will drip on the passenger side from under the timing belt cover if you let the motor idle for 5 to 10 minutes. Look for the drips on the inside of the RF tire. If the water pump is leaking the timing belt will jump and bend all the valves.

- Q: My radiator light came on this morning i was running late for work so i topped it off with water (about twice a year the light comes on, it has only ever had to be topped off) and after about 20 minutes of driving it started to heat up, so i pulled over shut it offsomebody stopped checked the temp of the water in the reservoir, said it felt to only be about 100 degrees, but topped it off with more water. the gauge dropped right back down to being almost as cold as when you first drive it, but after about 2 miles it was right back up near the red line.I pulled over again there was steam coming off the engine. I stuck my finger in the water it felt warm, but nowhere near hot. I couldn't get it cool enough to finish driving to work. Does this sound like the water pump?If so, how long should this take a decent mechanic to replace?If not, what else could it be?

- The water pump could be clogged a bit or the radiator could be the problem. the water pump should not cost much, but if changing the water pump does not help, then you should take the vehicle to a radiator place to see if they could replace the radiator or clean out your current radiator.

- Q: I got my oil changed yesterday and took like a 3 hour drive and back home and had no issues.. today I was at my work visiting and I noticed smoke coming from the engine [sort of more of steam] and a lot of smoke coming from the exhaust. The light on the gauge inside the car for the engine temp isn't working but all the other ones are. A mechanic told me it was a bad water pump, but I just want some more opinions. Or if the oil change could of effected that.. My engine coolant wasn't that low but a greenish liquid was really leaking from underneath the car.

- An oil change does not make a water pump go bad. Nor does the lack on an oil change. They just go bad over time. Just because there was steam like smoke coming from the exhaust system does not mean there is a water pump problem (water is a natural by product of combustion). Now the green fluid does mean that you have a coolant leak. But that could be because the reservoir was over filled when the engine was serviced. Some shops top off all fluids, and if the tank is over filled the excess has to go some where. But if could be a bad water pump. If so there will be water coming from the weep hole on the water pump. It could also be a bad hose. So unless I craw under it and take a good look, I don't know. If you do replace the water pump, and you have a timing belt that can be replaced, spring for the extra parts because in many cases the labor is already being paid for and the parts are less expensive then the labor at a later date. FYI: I do water pumps every other belt replacement for this reason.

- Q: hooking up a water pump to my tank and need a power supply

- whrere does red wire go and where does brown wire go

Send your message to us

Double Suction Split Case Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords