Diesel The Engine Sewage Submersible Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

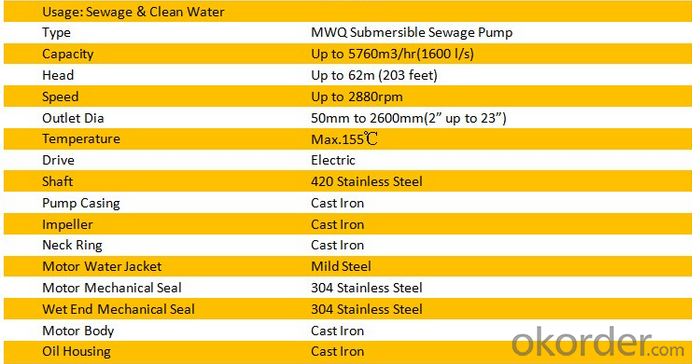

Specification

Diesel The Engine Sewage Submersible Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

My company has organized product research and development team, experienced high, intermediate technical staff.

Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.

Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

My company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.

Relevant product standards (enterprise), metrology, standardization management system, etc.,

have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and aftersales service, are performed according to the system management standard.

Application

This series pump is widely used for sewage treatment of city construction discharge for architecture projects, hotel, mine, pond, dyeing and printing, paper making and textile industries.

It is the ideal tool for transportation of sludge, slurry, living sewage, feces and stale wastes, solid grains fiber, paper chips, sandy soil etc.

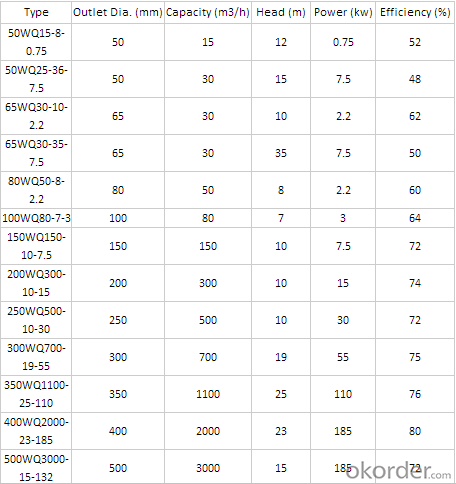

Model Description

100 WQ 50-30-3

100: Drain aperture (mm)

WQ: Submersible sewage pump

50: Capacity (m3/hr)

30: Head (m)

3: Power (kW)

Operations Conditions

1. The medium temperature should not be over 60oC, the density 1200Kg/m3, and the pH value within 5-9.

2. During running, the pump must not be lower than the permitted lowest liquid level.

3. Rated voltage 380 V, rated frequency 50 Hz. The motor can run successfully, only under the condition the deviations of both rated voltage and frequency are not over ± 5%.

4. The maximum diameter of the solid grain going through the pump has not to be larger than 50% of that of the pump outlet.

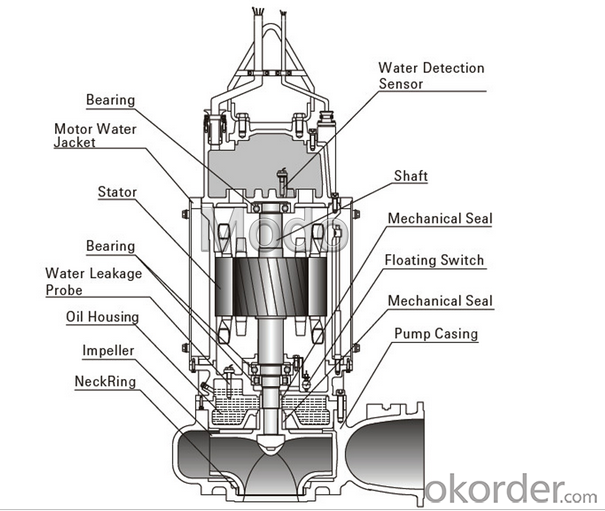

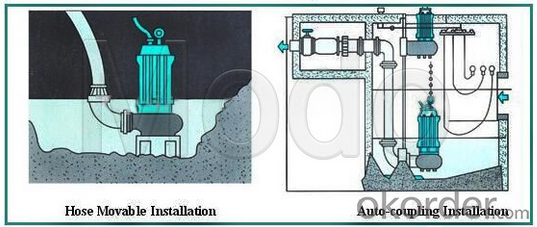

Pictures Show

Trading market

Transportation

- Q: HiThe well in my house is around 60 feet(20 meter). And the tank is 10 meter above the ground. My pump is Kirloskar Jet 1.5HP . It use to fill 500 Liter tank in 20 minutes. But now a days it is taking around 45 minutes to fill in. The pump is around 10years old. But it sounds good. Is it a problem with Pump or something else like Foot valve, Pipe, Pressure adjustment etc? . Do I need to change the pump? Which one is best suit for my well?. Submersible or Jet or something else?

- Jet pumps aren't particularly efficient, and at 10 years of age, it could be worn. However, the water table might be dropping, too (this is happening in a lot of places), and that alone could explain the longer time. Submersible pumps are much for efficient but more expensive to install.

- Q: what is NPSH for the water pump. Can you anyone explain in details? How can it calculate?

- NPSH stands for Net Positive Suction Head. It usually refers to the amount of pressure needed at the inlet of the pump for the pump to work properly. If there is insufficient pressure pushing the fluid into the pump, and the pressure at the inlet is lower than the NPSH requirement, then the pressure will be so low in the sucking center of the pump that the fluid will boil (this is called cavitation). It usually makes a racket, reduces pump performance, and erodes away the pump. To make sure this doesn't happen you have to have enough head (as in some level in the tank feeding the pump) and low pressure drop on the way to the pump (meaning big enough lines, no obstructions, and not too many bends). Some pumps are designed for very low npsh requirements. These pumps can suck water from some depth without cavitating. No pump can suck room temperature water from fore than about 25 feet below the pump, because the vacuum needed to lift the water 25 feet or so is close to the vacuum needed to boil water at room temperature. You cannot easily calculate the npsh a pump needs. This is a function of the design and geometry of the pump. You can calculate the delivered npsh by figuring the pressure of the liquid in the feed tank (don't forget atmospheric pressure) and subtracting the pressure loss due to friction in the piping between feed tank and pump. This loss will be a function of flow rate. Faster flow, more frictional pressure loss.

- Q: Who can tell me such water pump medium flow direction should be what kind of, from left to right, or from right to left, is low into the higher?

- Low inlet and outlet

- Q: how does a water feature pump work?

- Hi. Most pumps work by squeezing the water through a nozzle. A water feature pump is usually hidden from view but still works the same way as any other pump. A motor turns the device that pushed the water.

- Q: I just had the water pump replaced, now less than a week later it is overheating again and sometimes blowing cold air. What does this sound like it would be?

- Hi so when was the radiator cap last changed as the spring becomes weak over time and the engine appears to boil over.so a new radiator cap usually fixes this problem.

- Q: Could someone tell me the procedure for removing & installing a water pump on 97 buick skylark 3.1L 3100 SFI?

- wow.. lol, did ya look that up in a book. very precise..lol, but kinda correct.. being i work for gm and all..lol... simple hand tool will do it.. listen to the guy who copies it from a book.....loll..lol

- Q: how to replace water pump in a 96 F150?

- 1. drain coolant 2. remove engine fan and clutch assembly 3. remove radiator hose connection at water pump 4. remove water pump 5. clean water pump to engine mating surfaces 6. install water pump with water pump gasket 7. rest of installationin reverse order of removal

- Q: What is the reason that the water supply of pump is getting smaller?

- What kind of pump is it, home pump or factory pump? Single stage impeller or multistage impeller? Vertical or horizontal? Is it single suction or double suction? Different structure of the day pump has different causes of failure. But in general, there are several aspects: 1., the water inlet is small, the inlet pipe is blocked; 2., the blade is worn or broken; 3., the motor speed drops; 4., sealing serious leakage; 5., cavitation phenomenon.

- Q: Hubby is trying to change the water pump on our GMC Jimmy. He cannot get the fan off to access the water pump. What is the trick here? He's trying to do more of the maintenance on our cars to save $$$$ --but it sure is a bear!

- First look at the new water pump, you will notice the threads are either left or right hand threaded. Once you have determined the thread direction, you will know in what direction to remove the fan. Take a large drift punch and place it on the high side of the fastening bolt. strike it with a hammer and the jolt will loosen the grip of the bolt and allow you to remove it. This may take several tries, but it does work, I have used the process numerous times.

- Q: Pump performance parameters have three sets of data, how to understand the flow, lift, flow speed

- 1, the head is composed of a water pump design decisions, such as motor speed, power, blade shape; the flow is determined by the motor power and lift, the same power lift higher flux is small; velocity determined by flow and pipe section with a pump pipeline section greater velocity.2, the pump is to transport liquid or liquid pressurization machinery. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

Send your message to us

Diesel The Engine Sewage Submersible Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords