Centrifugal Hot Oil Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.RY centrifugal hot oil pump2.Reasonable structure

3.Use reliable

4.Long service life

5.Applicated to high temperature

RY centrifugal hot oil pump

Advantage

1.simple structure

2.good performance

3.reliable operation

4.high-temperature

5.small volume,save cost

Brief introduction

RY Thermal oil pump series is made with advanced technology and have high efficiency.

It can work steadily long without leakage under heat conditions. It has no additional cooling system and can be used safely and reliably. It’s widely used in the thermophore heating system in our country.It’s entered a lot of industry fields such as petroleum, rubber, plastic, pharmacy, spinning,

printing and dyeing, road building, food and so on, used to transport weak-corrosive high temperature.the liquid not containing solid granules. The using temperature is ≤370°C,and it is an ideal thermal oil circulation pump.

Application scope

Capcacity: 1-500m3/h

Temperature: -20°C-350°C

Head: 10-125m

Theory: Centrifugal Pump

Application: petro-chemical,oil industry,plastic and rubber industry etc

Typical Application

1.Petroleum Industry

2.Chemical Industry

3. Pharmacy and Health

4. Environmental and Water treatment

5.electroplating industry

6.Environmental protection

7.food service industry

8.Printing and dyeing area

9.textile industry, etc

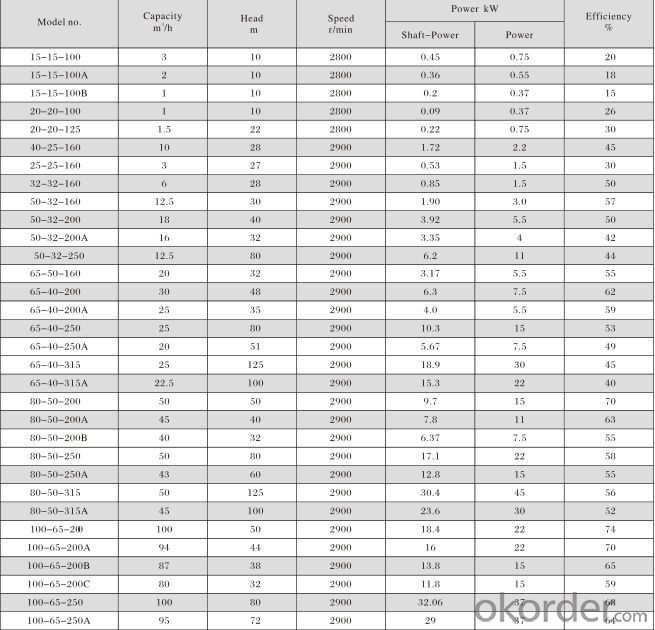

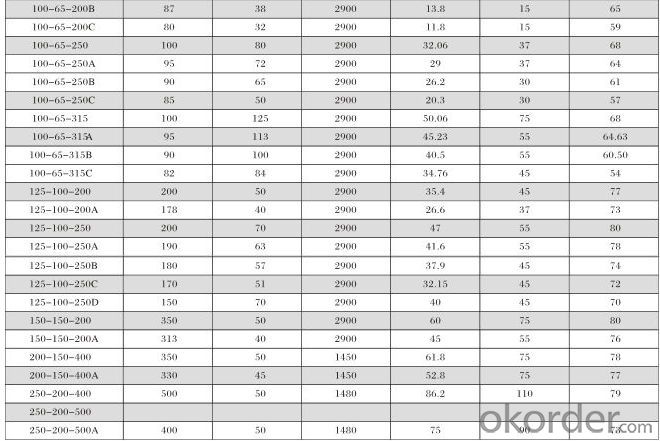

Technical data

.

- Q: What is the minimum continuous flow of a pump?

- Quality solutionsMinimum flow of pump, minimum continuous flow of pumpIn order to ensure the proper use of the pump and the normal operation of the pump manufacturer will indicate the minimum pump in the sample of the continuous operation flow, the correct selection or use to warn or instruct users. According to the provisions of the API standard, the minimum continuous flow into the minimum continuous stable flow and continuous flow. Most small thermal limit(1) the minimum continuous stable flow.API standard specifies the minimum continuous stable flow refers to the vibration limit does not exceed the standard set by the pump can work normally. The minimum flow pump at small flow rate, there will be noise and vibration increase, API of this provision is to ensure that the service life of the pump, avoid due to improper operation of the pump caused by the adverse effects.

- Q: What is the Rhodes pump?

- Best answerRoots vacuum pump (referred to as: Roots pump) refers to the pump is equipped with two opposite direction of synchronous rotation of the leaf rotor, rotor, rotor and pump housing between the walls of a small gap and no contact with a variable capacity vacuum pump.Roots vacuum pumps have been tested for long time in the fields of petroleum, chemical, plastic, pesticide, steam turbine rotor dynamic balance and aerospace simulation, so it should be popularized and applied in china. It is also widely used in petroleum, chemical, metallurgical, textile and other industries. Vacuum pump fittings are used for noise control of vacuum pumps, vacuum pump silencers.

- Q: Water pump can not be pumped out, how to maintain water?

- The pipe leaks or leaks:The nut may not pinch well when it is installed. If the leakage is not serious, it can be coated with cement or mixed with asphalt oil in the places where the gas leaks or leaks. Temporary repairs can be done with wet mud or soft soap. If the leakage at the joint, you can tighten the nut by hand. The leak is critical and must be re assembled.

- Q: How to install, operate and maintain the pipeline booster pump?

- When the pump leaks, check it immediately to prevent leakage. If it leaks with the motor connection, replace the mechanical seal. Check that the power is connected. Is the supply voltage consistent with the operating voltage of the pump?. If the above a and B are normal, please remove the pump, open the pump cover, remove the foreign body in the pump, and then pump the lid on, and then tighten it to normal.No water pump, pump installed in the tap water pipeline, such as tap water level in the pump impeller on the plane (horizontal installation) or center line (vertical) below, you should turn off the power supply, to tap water level rise more than the impeller plane or the center line, connected to the power supply, to avoid mechanical damage (automatic no need to turn off the electric type). When the pump used in pumping wells, please check whether the water inlet pipe leak; pump cavity storage is not enough, should be filled with water, whether the suction process is too high, proper adjustment. Check whether the inlet and outlet diameter is too small or blocked. Automatic type after a period of time, there may be automatic failure phenomenon, mainly stainless steel and other metal products in pipes, long-term precipitation to shut off the power supply after unloading, unscrew the top screw, remove the plastic sheet to be cleaned, and then, according to the original reset, the normal debugging, can be re used.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- Product featuresThe integrated structure of motor and pump adopts static seal, so that the pump is completely free of leakage;Full closed and no leakage structure, can transport toxic and harmful liquid substances;The shielded water-cooled motor and the cooling fan are removed to make the pump operate in a low noise and quiet condition. The utility model is suitable for occasions with high environmental noise requirements;

- Q: What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- This is a classification problem.Rotary is classified by movement, vane pumps are rotary, volumetric pumps are mostly rotary, piston pumps, etc., is reciprocating.

- Q: Is the flow meter in front of the pump or after the pump?

- After the flowmeter is placed in the pump, it is better to add a pressure tank or a buffer tank, so that the flow meter will work better

- Q: What is a feed pump?

- Feeding the role of the pump is to make the injection pump inlet pressure, increase the injection pump inlet pipe flow rate, in order to ensure high pressure water injection pump has sufficient supply.

- Q: Hydraulic pump displacement refers to the pump shaft what?

- You can see the sign of your hydraulic pump. There will be a displacement **ml/r in the sign of the hydraulic pump (r stands for every turn, ML is milliliter)

- Q: Why is the sewage pump device coupler?

- 2. automatic coupling device of the sewage pump coupling device has compact structure and small occupation area. Because the sewage pump is submerged, it can be installed directly in the sewage tank, and no special pump room is needed to install the pump and pump. It can save a lot of land and infrastructure costs.

Send your message to us

Centrifugal Hot Oil Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords