SK-3A water ring vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SK-ASeries

Based on SK series, is designed specially for the use of plastics industry. Therefore, many problems have been solved, for instance: incapability to work continuously, in case of sufficient wafter to be draw-out, dirts is resulted from sewage, impossibility to restart work after long pause. It is widely used in Tubing and Molding machinery.Items:SK-0.15A、SK-0.3A、SK-0.5A、SK-0.8A、SK-1.2A、SK-2A、SK-3A,Motor power:0.55~5.5KW,extract capacity :0.15~3(m3/min),Limit vacuum:-0.095MPa。

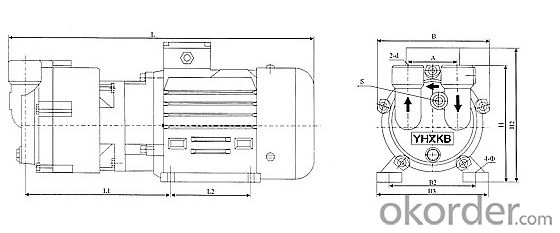

■List of size performance

■List of installation

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What is a water pump coupling device?

- The water pump coupling device comprises a coupler, a coupling flange, a guide rod and an upper fixing plate, wherein the contact surface of the coupling base and the coupling slide plate is provided with an annular groove, and a soft sealing gasket is tightly fixed on the groove. By adopting the structure, the coupling contact surface of the coupling slide plate and the coupling base is sealed firmly by an annular sealing groove

- Q: What is the minimum continuous flow of a pump?

- At'-- the allowable temperature rise of pumping medium,C- pumping medium specific heat, kj/ (kg DEG C);Ho- off dead center lift, M.Minimum continuous flow minimum continuous stable flow and minimum continuous thermal flow and the maximum value in the selection, or use the pump process, the minimum continuous flow process requirements must be greater than the minimum flow rate of the pump, otherwise it will cause the pump cavitation, vibration and noise, so that the pump parts damaged. If the minimum continuous flow the pump can not meet the minimum requirement's process, can install the bypass reflux device or reflux system in the pump pipeline, to ensure that the minimum continuous flow pump.

- Q: What are the advantages and disadvantages of the pump control system and valve control system in the hydraulic system? How to choose in the project?

- Valve control system is generally used for open systems, through the proportional valve or servo valve flow changes to control the motor or cylinder actuator action. The advantages of the system are energy saving, heat generation, and control accuracy. The disadvantage is that the system is complex and the cost is higher.

- Q: What is double hydraulic pump?

- [double hydraulic pump] the same drive shaft drives the rotation of two pumps, which are connected together and driven by an electric motor. The suction port of the pump is common, and the oil pressure port is separated from each other. Pump output of two shares of flow can be used alone, can also be used in parallel. This pump, a pump can play the function of two pumps. For example, there are two pumps on the loader, a pump acting as the work, a pump acting as the steering, and the double linked pump can replace the functions of the two pumps. It works by coupling the two pumps at the same time.

- Q: What kind of motor does the hydraulic pump need?

- Hydraulic pump is a power component of hydraulic system. It is driven by an engine or an electric motor. It draws oil from the hydraulic tank to form a component of the pressure oil which is sent to the actuating element. Hydraulic pump according to the structure is divided into gear pumps, piston pumps, vane pumps and screw pumps.

- Q: Does the reservoir water heater press the booster pump (high marks)?

- The outlet water pressure of hot water is the same as that of cold water. The water heater is pushed by cold water to push out the hot water. (of heating). Installation location about 2 meters away from the ground, the impact of water pressure is not large, in rural areas, the installation position in more than two buildings will have an impact. In the city, the installation position is above four floor to affect the water pressure.

- Q: What should be used to pay attention to the use of mechanical pumps?

- Overall: large pump should first do a good job of the foundation, to find a good whole, fixed, and motor, pump should be added good oil, the first test of the motor, and then conjoined test

- Q: If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- The air pump.The pump itself is mechanical failure.The pump outlet valve core off.Low voltage power.

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Reasonable, no valve, how to debug, overhaulGenerally installed on imports of valves of relatively large Cv value

- Q: What's the difference between a centrifugal pump and a centrifugal pump? What are they used for?

- As the name suggests, centrifuges are machines that achieve centrifugal effects by centrifugal action. And you say the centrifugal pump is only specific, and the same as the pump

Send your message to us

SK-3A water ring vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords