SK-4.5D water ring vacuum pump with flange port

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SK-DSeries

SK-D series of plastic machinery industry is the ideal vacuum pumps, vacuum pump SK is based on the specific requirements of the plastics industry developed. The suction pump to solve a lot of water in the conditions can not be continuous, severe hard water scaling can not start down a long time and so on. Widely used pipe machine, profiles and other equipment.Items:SK-2D、SK-3D、SK-4.5D、SK-6D,Motor power:4~11KW,extract capacity:2~6(m3/min),Limit vacuum:-0.095MPa.

■List of performance

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

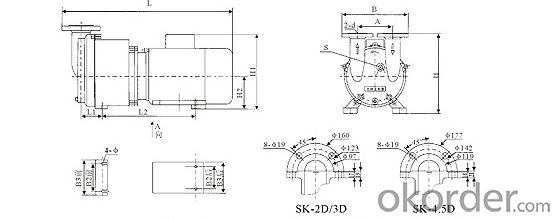

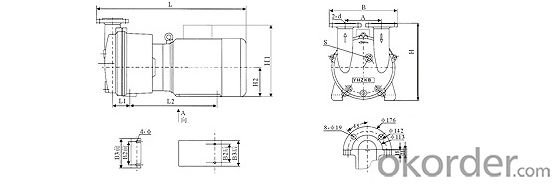

■List of size installation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

■List of size installation

type of pump | L | L1 | L2 | A | B | B2 | B3 | H | H1 | H2 | 2-d | 4-φ | S | ||

Before | After | Before | After | ||||||||||||

SK-6D | 854 | 103 | 481 | 200 | 380 | 300 | 254 | 357 | 315 | 425 | 400 | 160 | φ66 | 16 | G1/2" |

- Q:When the water pump is started, why should it start when the outlet valve is closed? Thank you

- The valve opening pump is aimed at the centrifugal pump.From the power curve of the centrifugal pump, the power of the centrifugal pump increases with the increase of the flow rate; the flow curve of the centrifugal pump shows that the flow rate of the centrifugal pump decreases with the increase of the head.

- Q:You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q:What are the reasons for sealing damage of centrifugal pumps?

- The reasons for sealing damage of centrifugal pumps are as follows: six, the specific contents and handling methods are as follows:First, the centrifugal pump water quality is poor, containing particles.As a result of poor water quality, containing small particles and medium hydrochloride content is high, forming abrasive wear, centrifugal pump seal plane or pull the surface, resulting in groove, ring groove and so on.Treatment method: improve water pressure or medium, replace machine seal.

- Q:What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- A single-stage pump is a pump with only one impeller. 2, a multistage pump is a pump with two or more impellers. The multistage pump can increase the pressure and lift the head higher. Level 1 means a booster impeller.

- Q:Why should I pump the pump before starting the centrifugal pump?

- Only centrifugal water can be pumped out of the centrifugal blade to generate negative energy at the entrance. There is no water diversion. Only the negative pressure produced by the air is too low to absorb the well water.Water pump has been pumped, centrifugal pump or can not start normally, mostly because of the water pipes and air

- Q:How to select metering pump head?

- In metering fluoride, we recommend the use of Viton, sealed PVC pump head. For most chlorination applications, it is better to use EPDM sealed NP (plexiglass) pump head. For hydrogen peroxide mixtures, only PTFE sealed PTFE pump head or stainless steel pump head can be used

- Q:Metering pumps related matters

- 2) change the metering pump diaphragmTrouble is often encountered when the old diaphragm is removed. Provide some additional advice on how to remove the old diaphragm.After in the pump head loose, remove the pump head before the stroke length adjustment to the 10% position. To ensure that the electromagnetic axis has sufficient pressure to maintain its connection firmly, so that you can unscrew the diaphragm.The pull end torque from the Jack out of the screw. Seize the liquid counter clockwise rotation. There is a slight resistance that can unscrew the diaphragm.Chemical 3 measurement may end in fluid crystallization, resulting in a one-way valve ball and seat valve does not work.In the end inhalation metering pump may have a gas leak. Hydraulic end suction side connector may lack O ring or suction valve connection loose.3) flow monitoring and measurement of a high viscosity medium, in the process of liquid delivery received a flow failure signal, how can we solve this problem?Move the hydraulic end by loosening the 4 pump head screws. Rotating stroke length to 10%, and seize the hydraulic end, and then slide out of the screw hole, then the screws do not touch them, but still control the back and diaphragm. Then rotate the component counter clockwise, with a slight resistance, and the diaphragm will loosen from the electromagnetic axis. If the diaphragm is not loose, use some grease on the contact surfaces of the diaphragm and the electromagnetic shaft. After a few minutes, gently tap the diaphragm with a small plastic hammer. Then proceed again in accordance with the above description.

- Q:What are the conditions required for hydraulic pumps to complete oil absorption and compression?

- There must be one or more sealing volumes, and the volume of work is variable;

- Q:What is the liquid pump? What are their categories? What are their strengths and weaknesses?

- The air driven liquid pump adopts compressed air driving method, and has the following advantages:The pressure can be adjusted by manual pressure control valve or air control valveIt is driven by air and is especially suitable for explosion protection applicationsAble to achieve pre-set final pressureAutomatic pressure relief by pumpLong term conservation without consuming energyWhen holding pressure, medium will not overheatThe utility model has the advantages of convenient installation and low maintenance cost, and only needs to connect the gas source, the inlet pipeline and the pressure pipelineReliable operation, low maintenance cost and little noise at the time of operation

- Q:How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- If you're allowed to spend a minute, you can do it 20 times a minute, and that is, the amount of water you sprinkle at a time (1000) is *20.1000 (ML) *20=20000 ml =20 liters, this is the flow,Here is a formula for you to see,Pump displacement * pump speed = flow,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SK-4.5D water ring vacuum pump with flange port

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords