Chemical Process Pumps with IH Series for High Temperature

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

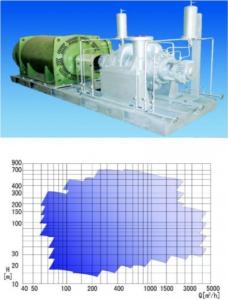

1.Specifications of Chemical Process Pump• Industrial chemical pump

• For corrosion liquid

• Easy maintenance,High efficiency

• OEM order is accepted

• Good quality and service

2.Main features of Chemical Process Pump

Chlor-alkali industry: lye, electrolyte, refined salt water of ion film caustic soda, chlorine solution, sodium hypochlorite, hydrochloric acid, sulfuric acid.

Iron and steel industry: electroplating, pickling, etc;

Paper-making industry: agents, bleaching liquid, sewage, etc;

3.Specification of Chemical Process Pump

| Model | Capacity | Head | Speed | NPSHr | Efficiency | Power(N)(kW) | Weight | |

| Q(m3/h) | H (m) | n(rpm) | r(m) | η (%) | Shaft power | Motor power | w(Kg) | |

| IH50-32-125 | 7.5 | 22 | 2900 | 2 | 47 | 0.96 | 2.2 | 34 |

| 12.5 | 20 | 2 | 60 | 1.13 | ||||

| 15 | 18.5 | 2.5 | 60 | 1.26 | ||||

| IH50-32-125A | 6.7 | 17.5 | 2900 | 2 | 45 | 0.71 | 1.5 | 33 |

| 11.2 | 16 | 2 | 58 | 0.84 | ||||

| 13.5 | 14.7 | 2.5 | 58 | 0.93 | ||||

| IH50-32-160 | 7.5 | 34.3 | 2900 | 2 | 44 | 1.59 | 3 | 39 |

| 12.5 | 32 | 2 | 54 | 2.02 | ||||

| 15 | 29.6 | 2.5 | 56 | 2.16 | ||||

| IH50-32-160A | 7 | 30 | 2900 | 2 | 42 | 1.36 | 2.2 | 38 |

| 11.7 | 28 | 2 | 52 | 1.71 | ||||

| 14 | 26 | 2.5 | 54 | 1.83 | ||||

| IH50-32-160B | 6 | 25.8 | 2900 | 2 | 40 | 1.05 | 1.5 | 37 |

| 10 | 23 | 2 | 50 | 1.25 | ||||

| 12 | 21 | 2.5 | 52 | 1.32 | ||||

| IH50-32-200 | 7.5 | 52.5 | 2900 | 2 | 38 | 2.82 | 5.5 | 43 |

| 12.5 | 50 | 2 | 48 | 3.54 | ||||

| 15 | 48 | 2.5 | 51 | 3.95 | ||||

| IH50-32-200A | 7 | 45.3 | 2900 | 2 | 37 | 2.33 | 4 | 42 |

| 11.7 | 44 | 2 | 46 | 3.05 | ||||

| 14 | 41.5 | 2.5 | 49.5 | 3.2 | ||||

| IH50-32-200B | 6.5 | 39.6 | 2900 | 2 | 36 | 1.95 | 3 | 41 |

| 10.8 | 37.5 | 2 | 45.5 | 2.42 | ||||

| 13 | 36 | 2.5 | 48.5 | 2.63 | ||||

| IH50-32-250 | 7.5 | 82 | 2900 | 2 | 28.5 | 5.87 | 11 | 75 |

| 12.5 | 80 | 2 | 38 | 7.16 | ||||

| 15 | 78.5 | 2.5 | 41 | 7.83 | ||||

| IH50-32-250A | 7 | 72 | 2900 | 2 | 28 | 4.9 | 7.5 | 74 |

| 11.7 | 70 | 2 | 37.5 | 5.95 | ||||

| 14 | 68.5 | 2.5 | 40 | 6.53 | ||||

| IH50-32-250B | 6 | 61.5 | 2900 | 2 | 27.5 | 3.65 | 5.5 | 73 |

| 10 | 60 | 2 | 36.5 | 4.48 | ||||

| 12 | 58.5 | 2.5 | 39 | 4.9 | ||||

4.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- (1) the disk, stator or bushing is worn and shall be inspected, trimmed or replaced with a rotary vane vacuum pump.(2) the pump temperature is too high, which not only reduces the viscosity of the oil, increases the saturated vapor pressure, but also may cause cracking of the pump oil. Ventilation, cooling and environmental temperature should be improved. If the exhaust gas temperature is too high, should be cooled before entering the pump, the environment temperature is high, should try to use a better high speed vacuum pump oil or 3# diffusion pump oil. (10) because of the deformation, wear or movement of the parts, the maximum opening height of the check head can be reduced or even unable to be opened, the intake of oil is too little, and the vacuum degree of the rotary vane vacuum pump is reduced, and should be adjusted as shown in the assembly section. Open high, more oil, but open too high, check valve in some places on the stop, it will not automatically drop, lost to prevent oil returns. The commonly used rotary vane vacuum pumps mainly include double stage rotary vane vacuum pump and single-stage rotary vane vacuum pump

- Q: The function of centrifugal pump

- 4, bearings are set on the pump shaft supporting the pump shaft components, there are two kinds of rolling bearings and sliding bearings. Rolling bearings use butter as a lubricant, refueling should be appropriate, generally 2/3 ~ 3/4 of the volume is too much, will heat, too little, there is noise and fever! The plain bearings are made of transparent oil as a lubricant and fill up to the oil level. Too much oil will leak out along the pump shaft and float *, too little, the bearings will overheat and burn out, causing accidents! In the pump running process, bearing temperature is highest in 85 degrees, generally run at about 60 degrees, if higher, will find the reason (whether there is impurities, whether the oil is black, whether water) and timely processing!

- Q: What is the name of the day pump and ground pump? Specific introduction

- People often say "day pump" actually refers to the boom pump, it also has many other name, such as pump, boom pump, concrete pump, concrete pump truck, these words are "day pump".Ground pump, in fact, refers to the pump drag pump. Therefore, to understand the difference between day pump and ground pump is to understand the difference between the boom pump and the tow pump

- Q: Pump unloading in hydraulic transmission,

- Unloading is pumping oil directly back to the tank, the pressure is very low, energy saving

- Q: Concrete pump 125 pipe wall thickness

- Currently mainly divided into gate valve, concrete pump and S valve concrete pump. Another is a pump consisting of a pump body mounted on an automobile chassis and fitted with retractable or bent cloth poles

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Important equipment for deep well water extraction. When in use, the whole unit dives into the water. The extraction of groundwater to the surface is water, mine rescue, industrial cooling, irrigation, water lifting, ship ballast, also can be used in fountain landscape, hot water submersible pump for hot spring bath, but also can be applied to the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects. The utility model is mainly used for farmland irrigation and water for human and livestock in mountain areas, and can also be used for central air conditioning cooling, heat pump units, cold pump units, cities, factories, railways, mines and site drainage. General flow can reach (10m3~650m3) per hour, head up to 1500 meters.

- Q: Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- Select the hydraulic pump from the following considerations:1. hydraulic pump pressureHydraulic pump operating pressure is the pump (or motor) in actual work output (or input) oil pressure, determined by the external load.Rated pressure refers to the maximum pressure under continuous running in accordance with the test standards under normal working conditions. The size of the pump is limited by the service life, and the service life of the pump (or motor) will be shorter than the design life if it exceeds the rated pressure. When the work pressure is greater than the rated pressure, it is called overload.

- Q: Metering pumps related matters

- 2) change the metering pump diaphragmTrouble is often encountered when the old diaphragm is removed. Provide some additional advice on how to remove the old diaphragm.After in the pump head loose, remove the pump head before the stroke length adjustment to the 10% position. To ensure that the electromagnetic axis has sufficient pressure to maintain its connection firmly, so that you can unscrew the diaphragm.The pull end torque from the Jack out of the screw. Seize the liquid counter clockwise rotation. There is a slight resistance that can unscrew the diaphragm.Chemical 3 measurement may end in fluid crystallization, resulting in a one-way valve ball and seat valve does not work.In the end inhalation metering pump may have a gas leak. Hydraulic end suction side connector may lack O ring or suction valve connection loose.3) flow monitoring and measurement of a high viscosity medium, in the process of liquid delivery received a flow failure signal, how can we solve this problem?Move the hydraulic end by loosening the 4 pump head screws. Rotating stroke length to 10%, and seize the hydraulic end, and then slide out of the screw hole, then the screws do not touch them, but still control the back and diaphragm. Then rotate the component counter clockwise, with a slight resistance, and the diaphragm will loosen from the electromagnetic axis. If the diaphragm is not loose, use some grease on the contact surfaces of the diaphragm and the electromagnetic shaft. After a few minutes, gently tap the diaphragm with a small plastic hammer. Then proceed again in accordance with the above description.

- Q: Significance of water pump model ISO50-160

- Meaning of water pump model ISO50-160: ISO- stands for international standard code (IS). 50- indicates that the inlet diameter of the pump is 50 mm (the complete model IS50-32-160 32- indicates that the outlet diameter of the pump is 32 mm). 160- represents impeller diameter.

- Q: How long does the fine stone pump need maintenance? What should I pay attention to?

- nan

Send your message to us

Chemical Process Pumps with IH Series for High Temperature

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords