SK-3D water ring vacuum pump with flange port

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SK-DSeries

SK-D series of plastic machinery industry is the ideal vacuum pumps, vacuum pump SK is based on the specific requirements of the plastics industry developed. The suction pump to solve a lot of water in the conditions can not be continuous, severe hard water scaling can not start down a long time and so on. Widely used pipe machine, profiles and other equipment.Items:SK-2D、SK-3D、SK-4.5D、SK-6D,Motor power:4~11KW,extract capacity:2~6(m3/min),Limit vacuum:-0.095MPa.

■List of performance

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

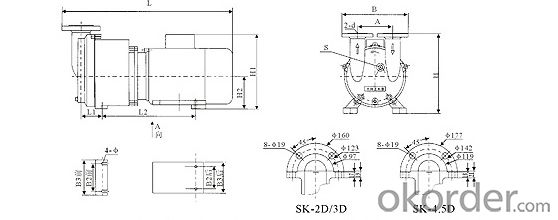

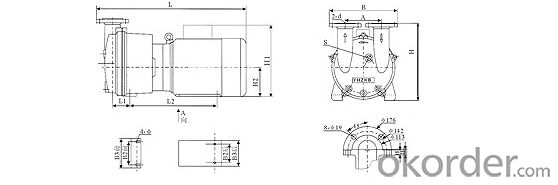

■List of size installation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

■List of size installation

type of pump | L | L1 | L2 | A | B | B2 | B3 | H | H1 | H2 | 2-d | 4-φ | S | ||

Before | After | Before | After | ||||||||||||

SK-6D | 854 | 103 | 481 | 200 | 380 | 300 | 254 | 357 | 315 | 425 | 400 | 160 | φ66 | 16 | G1/2" |

- Q: Pump unloading in hydraulic transmission,

- Can be used for short-term shutdown, pump non-stopNo unloading, usually through the overflow valve back to the tank, high pressure, power, at this time insurable pressure, and so on

- Q: How many kinds of pumps are available and the operating principles of various pumps?

- The volume type pump, depending on the periodic change of sealing liquid containing space volume, the energy is periodically transmitted to the liquid, the liquid pressure increased to force the liquid discharge, according to the motion form of work elements can be divided into reciprocating pump and rotary pump. Other types of pumps transmit energy in other forms. As the jet pump work on high-speed jet of fluid will be required to transport fluid suction pump after mixing for momentum exchange in order to transfer energy; water hammer pump by water when braking in the flow of energy transfer is to rise to a certain height; the electromagnetic pump is energized to make the liquid metal in the electromagnetic forces generated in the flow and transport. In addition, the pump can also be classified according to the nature of the transmission fluid, driving methods, structure, use and so on.

- Q: Rules for operation of centrifugal pumps

- Operating rules:1, before starting to check whether the water pump foot loose, coupling shield, and motor fan blade cover is intact, in order to ensure the safety of equipment and personal safety.2. Check whether the inlet valve is open and open as fully as possible. Is the outlet valve closed, open the bleeder valve, exhaust until there is no air, and close the bleeder valve. At the end of the valve to the pipeline in the pump cavity filled with water.

- Q: Water pump does not produce water, what are the reasons?

- 4. as a water inlet valve, check whether it is normal, whether the silted up.5. the installation height of water pump exceeds the allowable suction height of pump, or the suction pipe is too long.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- Specification for concrete cylinders:Bore * stroke mm 200 * 1650Hopper capacity L 800Feeding height mm 1400Motor model Y2-280M-4Power kw 90Rated voltage V 380Rated speed r/min 1480Soft starter withoutHydraulic system open-loop

- Q: Is the flow meter in front of the pump or after the pump?

- After the flowmeter is placed in the pump, it is better to add a pressure tank or a buffer tank, so that the flow meter will work better

- Q: Is vane pump good or gear pump good?

- The main parts of a gear pump are gears that mesh with each other. The meshing driving gear and the driven gear are respectively arranged on two parallel rotating shafts. Because the gear teeth enter and exit the meshes, the volume of the teeth is changed, and the suction and discharge effect is formed.

- Q: How many square cables does the submersible pump for 7.5KW need?

- 7.5KW's submersible pump requires 2.5 square aluminum cables.Calculate the current value of submersible pump first:

- Q: Which nuclear submarines use the shaftless pump technology?

- At present, the submarine has been used in the pump jet technology, the most representative is the United States Virginia class submarine and the Russian North Sea God class submarines.. And shaftless pump is a derivative application of superconducting technology, which is more advanced than pump jet technology..If you want to learn more about shaftless pump technology, you can find relevant papers online.

- Q: How to maintain and repair the booster pump of pipeline pump?

- Installation and use1. use rubber washer and bolt to connect the pump flange at both ends and the pipe flange. In order to use and maintenance convenience, in the pump inlet and outlet pipelines should be installed with a regulating valve.2. open the inlet control valve, so that water into the pump, in order to keep the cavity filled with liquid (otherwise it will damage the seal), close the outlet valve.3. turn on the power and make sure the correct turn.4. make sure the pump starts and runs after turning.5. adjust the opening of the outlet valve so that the pump runs near the design point, depending on the rated flow and lift of the pump. [for this reason, it is better to place a pressure gauge near the outlet flange). Note: this pump is strictly prohibited to run without water, so as not to damage the seal.

Send your message to us

SK-3D water ring vacuum pump with flange port

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords