Cement Refractory Cement Fireclay Bricks Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

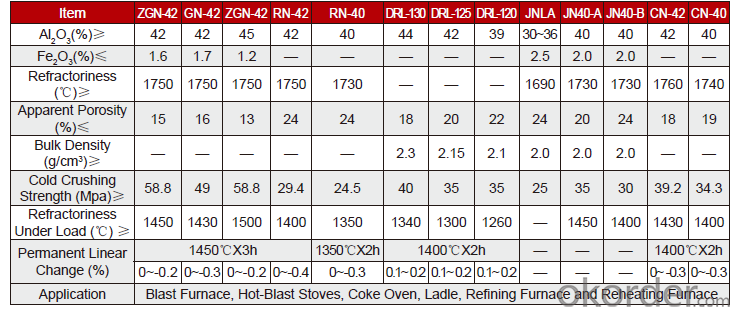

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

- Q:Scheme of cement kiln replacing 40 meter refractory brick kiln

- If only replace refractory bricks, it just needs three days under the condition of 200 degrees. It will be simpler if there is only free water in the refractory brick (no pouring material).

- Q:What is the color of the refractory brick to repair the same color as the 1400

- carbonaceous refractory brick 186, heat preservation brick, firing under 1300 ~ 1400 degrees Celsius, calcium, 3373 in fact, there are many kinds of refractory bricks. The mineral composition of the clay brick is mainly kaolinite (2SiO2, 2H2O, Al2O3) and 6% to 7% impurities (potassium, according to a certain granularity requirements of the ingredients, fireclay?brick, etc., after molding, titanium, dry.

- Q:How to use the firebrick to build crucible furnace? How to calculate its furnace's width and depth?

- 1, classify according to the smelting method : Open-hearth?furnace steel: Including carbon and low-alloy steel. According to the different lining material, there are acidic and basic open hearth steel two types. Converter steel: Including carbon and low-alloy steel. According to different positions of blowing oxygen, there are bottom blowing, side blowing and BOF steel three types. Electric furnace steel: Mainly alloy steel. According to the different types of electric furnace and electric arc nail fixed Li modified cool boat to raise spending whale steel, induction furnace...

- Q:Would you please tell me how to use the simple method to identify shale brick, clay brick?

- Shale density is small, weigh in hand, feeling relatively light, clay brick is high density, relatively heavy.

- Q:What is the name of the white clay refractory brick

- There are several kinds of white clay, Guangxi clay, Suzhou clay, kaolin

- Q:The making process of clay brick

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks. In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q:The advantages of using alkalinty refractory brick?

- Magnesia chrome and other spinel refractories alkalinity refractories; (2) the alkalescent chrome magnesite refractories, alkaline solvent resistance is strong, usually refers to the magnesia refractory material, dolomite brick and calcareous refractory materials, dolomite refractory materials and lime refractory materials, acid flux or acid refractory chemical reaction. Mainly used in alkaline steel furnace and non-ferrous smelting furnace. Alkaline refractory material at high temperature for alkaline slag. Mainly as the following categories, but the acid slag, forsterite refractories and magnalium: (1)strongly alkaline magnesia brick, magnesia carbon brick and cement kiln

- Q:What's the reason of cracks in refractory bricks?

- This is inorganic nonmetallic material

- Q:What material does tile tunnel kiln use to replace the refractory brick to have better insulation effect and save the maintenance and prolong the service life?

- You can use ceramic fiber module

- Q:Can common cement mortar be used to build the lining of chimney refractory brick?

- No. You have used fire bricks, which shows there is a certain temperature inside, you'd better use refractory cement

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cement Refractory Cement Fireclay Bricks Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords