Anchor Brick, Refractory Brick, Fireclay Brick for Ceramics Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refracotory brick is a refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

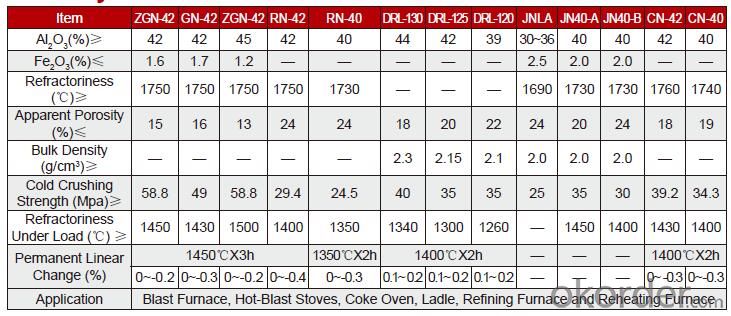

Technical data:

Packing:

- Q: What is refractory brick? What is refractory clay? ?

- Refractory brick is a kind of brick that is fireproof, refractory soil is the soil that is fireproof

- Q: several refractory brick of rotary kiln several is damaged, how many refractory bricks should be replaced?

- The life of refractory bricks in rotary kiln is generally short.

- Q: the refractory brick in glass furnace burner was burning, the bricks on both sides of the fire hole were burning the blocked it, what will cause brick burning?

- The firebrick in glass melting furnace is mainly consisted of zircon brick, other ordinary refractory materials can not effectively prevent the erosion of glass solution. Because the glass melting liquid is eutectic mixture compared to the refractory bricks, it penetrates into the refractory brick and reduces its original performance, simply speaking, the glass melting liquid dissolves the refractory bricks as eutectic mixture .

- Q: The state's policy on clay bricks

- Now the country for the solid clay brick is the policy of emerge of itself and perish of itself. Because solid clay bricks occupy resources, vigorously encouraging new brick, I was open brick reached up to four, but we have to see this with money the disease I do, I don't think they all sold, finally want to engage in a new type of brick, but in the investigation that model free burning brick cost is too high, and a lot of people are not optimistic, finally did not dare to engage in this, we also have the business,

- Q: Are refractory bricks poisonous?

- Zirconium minerals are often associated with other minerals in the mining, because the bricks are basically burned under more than 1 thousand degree. But some of the bricks contain heavy metal elements chromium. Some of the brick contains zirconium, the vast majority are very safe, and heavy metal elements have a certain toxicity, there are many kinds of refractory bricks that the nature is very stable, and the associated minerals are generally radioactive

- Q: What is the refractory brick of the electric furnace?

- there is no problem if it can be dismantled. And refractory brick material of every place is not the same, life is not the same. Buy some for backup , and change it once it is broken, there is no standard, the lining can be hit, as long as the induction coil can be fixed

- Q: Can you direct the clay brick walls embryo

- Times are different, where there is no modern calcination process. With glutinous rice water in the soil, but glue well, but there is no comparable with cement and other building materials. Not long, can not withstand weathering.

- Q: What kinds of annealing furnace refractory bricks there are?

- But the energy saving effect is good, but also can use lightwight heat insulating brick, but the price is higher than that of clay brick

- Q: How to prevent high alumina refractory brick from producing crack when reproduce high alumina refractory brick?

- 1-1, on the 1 in order to prevent the emergence of crack in the production of high alumina refractory brick. 2 is appropriate, the water absorption rate of the tube mill should be controlled below 6%, the excess air coefficient controlled between level 1 and 2. The water absorption rate of clinker of bauxite with high alumina controlled under 4%-5%, making the high aluminum refractory brick burning in a smoothly and steadily weak oxidation atmosphere, and should be adjusted by thermotechnic

- Q: MU10 what are the non clay solid bricks?

- Mu10 is the strength grade of bricks, divided into grades MU7.5, 10, 15, 20, 25, 30 and so on. Non clay brick "non sintered clay bricks, such as sand brick, shale brick, cement brick, fly ash brick etc..

Send your message to us

Anchor Brick, Refractory Brick, Fireclay Brick for Ceramics Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords