Fireclay Brick for Furnace Insulation - Refractory Brick Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

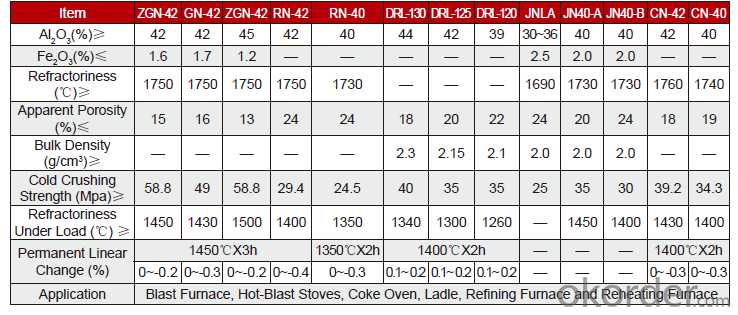

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What's the reason of cracks in refractory bricks?

- If it is made to refractory bricks,dry in the air naturally for 10 days, then put into the drying furnace, which is certainly better than the brick is put to the furnace directly, this is not easy to crack. After all, the moisture of brick will run in the air. See the semi-finished products (not crack is really no crack), but after drying, it has cracks, this is must because moisture runs quickly in a short time. If it cracks after high temperature heat treatment, the reason is very complicated, such as after high temperature burning, temperature decreases too fast, resulting in a large temperature change, then it cracks. Or in the process of high temperature heat treatment, the internal reaction is intense, and generate some volume expanding materials, resulting in cracks and so on. Mullite Petrochemical reaction, spinel reaction and so on, the reactions of a lot of materials are the volume expansion

- Q: what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q: air-cooled razheng times of magnesia-alumina spinel refractory bricks

- The ingredients are magnesium, oxygen, and aluminum. the components of spinel refractory can be magnesia-alumina spinel with excessive aluminium oxide, or magnesia-alumina spinel with excessive magnesium oxide. excessive magnesium oxide and aluminium oxide can form magnesia-alumina spinel in above 1700 degrees.

- Q: What are the disadvantages of sintered clay bricks?

- Disadvantages: FrostPan cream also known as cream, is salting out phenomenon in the process of using brick. The excess soluble salt in the brick is affected by water absorption and dissolves when water evaporates. When the crystal is precipitated, it expands and causes the brick surface to flake. Standard: excellent products without efflorescence, first do not allow secondary efflorescence, qualified products is not allowed to have serious flooding.Lime crackingLime burst refers to brick with limestone, turn after absorbing water, because the lime burst and the expansion of the gradually maturing. This phenomenon affects the quality of bricks and reduces the strength of masonry

- Q: the amount of per square refractory brick of Various specifications and thickness of the refractory brick wall

- 9 grams-47. 7 grams- 47 calculate by your own according to the actual volume; cubic centimeter; 2.2 grams Clay brick 2: 1; 3, high alumina brick 3; cubic centimeter; standard density, cubic centimeter: 230mm * 114mm * 65mm, diatomite insulation brick 0, you can calculate the reference value

- Q: Which is the higher price of concrete solid brick and MU15 fired common brick (non clay brick)?

- The price of concrete solid bricks and the price of MU10 bricks are on the same level, and the difference will not exceed two cents a penny. It should be MU15 sinter ordinary brick is more expensive.

- Q: how to test the high alumina refractory brick mixed alumina?

- The first thing before producing bricks is to test whether the aluminum content reaches the standards, general testing on raw materials. Second: the shaped high aluminum brick will be tested in some professional equipment, you can know it from the professional inspection departments.

- Q: Do slag bricks have clay bricks strong enough?

- Clay bricks you mean should be red bricks burned out of the fire.

- Q: What are the factors that determine the weight of the refractory bricks?

- (5) Under high temperature, the volume is stable, the inner part of brick will produce unrecoverable volume shrinkage or expansion because of the internal transformation. Therefore, masonry inner will produce stress to make the material break and peel off, and the weight of a ton of bricks is determined by the bulk density and quantity, how much is the weight of refractory bricks, refractory bricks should have the ability to resist the damage, the weight of a piece of brick is determined by the bulk density: Refractory bricks are used under high temperature for a long term: Refractory bricks in the use of the process. Cooltech refractory brick used in various high-temperature equipment: The temperature of some parts of metallurgical furnace and other industrial furnace is uneven due to rapid temperature change during operation. (3) good thermal stability: Refractory bricks should not only have a high fusion temperature, no softening deformation and collapse, causing damage to the masonry. (4) strong resistance to slag: Modern metallurgy and the other industrial furnace heating temperature is generally between l000~1800. Refractory bricks should have the performance that is not easy to melt under high temperature. Therefore. Therefore, it is subject to high temperature conditions of physical and chemical corrosion and mechanical damage, the refractory brick must have the ability to resist high temperature chemical corrosion, the volume of refractory brick is required to be stable under high temperature. (2) High-temperature structural strength, chemical corrosion of metal, but also should have been built in the stove brickwork load or other mechanical vibration, often has the high temperature slag, so the refractory materials performance should meet the following requirements: (1) high refractoriness

- Q: does the electric kiln burner need to be sealed?

- seal when open the kiln, and observe the temperature, when the temperature reaches a point, you can move the firebrick away, and continue observing the temperature to decide whether to seal it or not, but do not seal it completely, repeat the procudure until reach the sinter point or skill requirement.

Send your message to us

Fireclay Brick for Furnace Insulation - Refractory Brick Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords