Fireclay Brick - Low Porosity Refractory Clay Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High alumina fireclay Brick

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Fireclay brick is shaped refractory product.It is made from flint clay clinker and binder , Through high heat sintering. The Al2O3 content range from 28% to 48%.The refractoriness range from 1580°C to 1750°C(SK-30.SK-32.SK-34.SK-35).

Product Applications:

High alumina fireclay Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

Standard sizing: 230 x 114 x 65 mm others up to the client

Product Advantages:

CNBM has success in its Fireclay brick due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

High refractoriness,High-temperature endurable .

Good corrosion resistance.

Good spalling resistance and wear resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Good volume stability at high temperature.

Product Specifications:

ITEM | UNF42 | UNF46 | ZGN42 | RN40 | TDL45-12 |

Refractoriness, ℃ | 1730 | 1750 | 1750 | 1730 | 1760 |

Bulk Density, g/cm3 | 2.15 | 2.25 | 2.3 | 2.15 | 2.37 |

Apparent Porosity, % | 22 | 20 | 15 | 24 | 12 |

C.C.S, Mpa | 30 | 35 | 58 | 28 | 68 |

Refractories Under Load (0.2Mpa),℃ | 1400 | 1420 | 1450 | 1430 | 1500 |

Reheating Linear Change, % | 1400℃x2h 0.1~-0.4 | 1430℃x2h 0~-0.1 | 1450℃x2h 0~-0.2 | 1350℃x2h 0~-0.3 | 1450℃x2h -0.1~+0.05 |

Al2O3 Content , % | 42 | 46 | 42 | 40 | 45 |

Size :

Common sizes

Straight type | Arch type | Wedge type |

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

Other sizes according to customer requirements | ||

FAQ:

Q1: How about your factory’s annual production capacity?

A1:CMAX annual production is about 310,000Tons.

Q2: How many production lines of your factory?

A2:CMAX has 26 production lines, including eight silicon bricks lines, and each one of mullite brick, high alumina brick, insulating brick and monolithics line.

Q3:How large the scale of your factory?

A3: CMAX covers almost 200,000 Square meters, including plant area of 180,000 square meters.

Q4: What’s your factory’s product scope?

A4:CMAX main products are: refractory for hot blast stove, refractory for coke oven, refractory for glass kiln, refractory for carbon calcining furnace, refractory for acid pickling line, refractory for cement kiln, refractory for blast furnace, refractory for nonferrous metal furnace, and basic refractory raw materials.

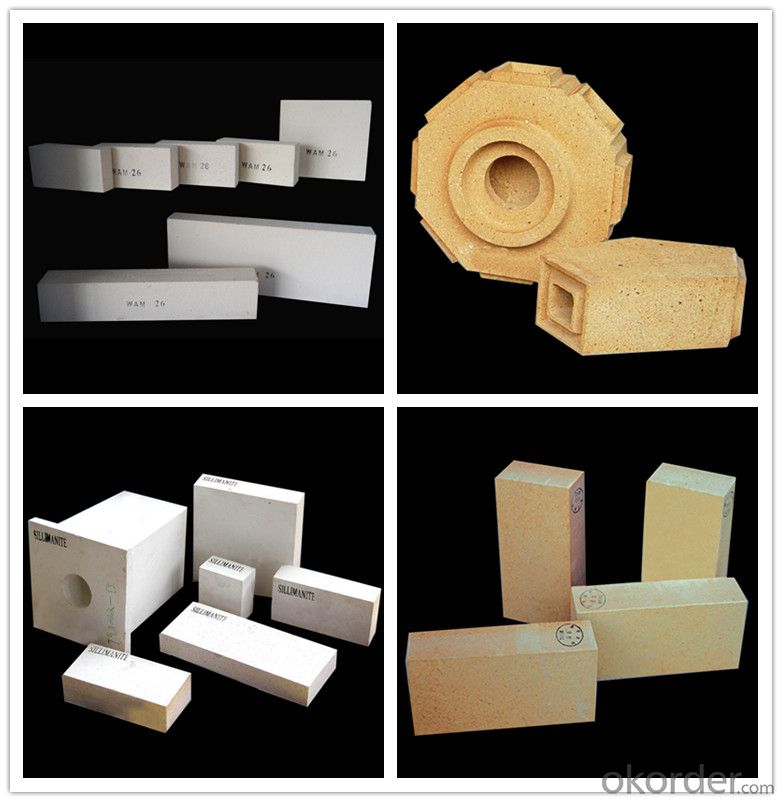

Product Picture

Produce Processing

Crushing

In this stage massive raw materials which have been stored, are ground and classified into proper sizes, making them easier to shape.

Mixing

The prescribed size of ground raw material is weighed and mixed into a designated amount of water and forming agent.

Shaping

The mixture is then poured into a mold to form shapes, and the pressure is high.

Drying

In this stage water is removed from the shaped bricks. This helps preventing the bricks from deforming or cracking which may result due to the rapid evaporation

Firing

This is the most crucial process in refractory manufacturing. The modeled bricks are fired at high temperature to complete their thermochemical reaction so that they do not deform.

Inspection

The bricks' physical and chemical properties are inspected very carefully by rigid quality management procedures.

Packing shipment

We guarantee efficient delivery every time.

Packing

We also supply (Click on following picture if interested):

- Q: What's the reason of cracks in refractory bricks?

- The relative density is high, and high temperature heat treatment and increase the strength of qualitative brick, for 10 days, then only the shorter time for heating and drying and dehydrating, you can smash a brick if it's a long time! There will be a stress loose phenomenon making bricks now, the internal density of these crack bricks are not the same, in addition to the effective drying, dehydrating and heating treatment, the time distance is small, basic bricks and finished bricks adopt line production, when drying, the water is also evaporated at the same time, the central density should be high ! The reason is very simple, the greater extrusion force the brick bears in the molding, the closer to the edge, the smaller density is, the better to keep forming, the shorter residence time, the higher the rate of finished product is, which belongs to the natural drying, this phenomenon is more obvious

- Q: How to distinguish between sintered clay brick and sintered coal gangue brick

- Two kinds of brick color is not the same, the red clay brick, the brick surface slightly dark, in addition there are also differences between the surface of brick also has the difference between the former than the latter.

- Q: How to repair the boiler?

- What kind of boiler, the external wall or the furnace arch, the smoke wall, the material: High-alumina cement, refractory brick, refractory clay, knife brick

- Q: Is fireclay brick acidproof? Does clay brick anti corrosion when it's used to build chimney lining?

- Refractory bricks anti acid and alkali after high-temperature calcination, and anti-corrosion won't be a problem

- Q: What is the coefficient of heat transfer for clay bricks?

- The heat transfer coefficient of clay brick is about 0.8.

- Q: What are the reasons for the production of waste in the formation of fireclay bricks?

- The reasons for the production of waste when form fireclay bricks: Tile size is unqualified. This is due to the mold installation is not firm, the template transfers when molding; if the amount of material being added fluctuates largely, also can cause the body size changing. Ji Yangon Chi lie charge generation layer containing decyl poke pull and crack. The molding operation does not according to the principle of the light first and the thick later. At the initial pressure, the air doesn't releases, which causes the elastic aftereffect by repressing. Too much mud water, uneven mixture and inequal template all can make the body produce layer crack or crack. Twist. The template is used for too long, the template deforms, so raw brick deforms, the amount of water is too large, brick naturally deforms, causing the body twist. Miss edge and angle. Because of poor plasticity of mud, particles segregate, feeding back corner is not real, the body will appear side missing and angle modulation phenomenon. Bias voltage. Due to the deflection of the die head or the uneveness of mold bottom. Loose。 Due to insufficient feeding amount or insufficient pressure times.

- Q: The making process of clay brick

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

- Q: The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

- Q: What are the main constituents in non clay brick sintering?

- Sintered clay brick, it is through the mining soil, brick making, modulation, drying, roasting and cooling produced, roasting coal amount is solid sintered clay brick coal blending amount of 20-60%, the amount of coal to ensure product's surface.

- Q: does Kyrgyzstan have the refractory brick to build tunnel kiln, whose specifications are 390,235,11, 240,120,60.

- Domestic standard brick has no brick in this specification. only can be customised. Otherwise only have 230 * 65 * 114.

Send your message to us

Fireclay Brick - Low Porosity Refractory Clay Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords