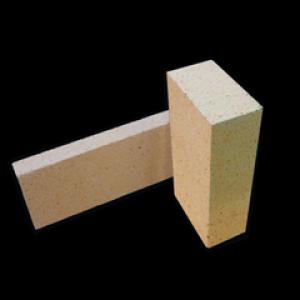

Fireclay Brick - Low Porosity DN18

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Low Porosity Fireclay Brick DN18

Our corporation produces a comprehensive range of Low Porosity Fireclay bricks, with 30% to 55% alumina content, all of these bricks exhibit excellent performance.

Our Low Porosity Fireclay bricks are the final result of blending excellent calcined flint clay and calcined bauxite, with cutting-edge technology, adding superfine powder, after mixing, drying, forming, in the high temperature shuttle kiln. We ensure you that the Fireclay Bricks made by us possess high quality standard and have gone through all the complicated quality control parameters. Their durability and strength adds life to the structure and they have the capacity of bearing high temperature.

Technical Data of Low Porosity Fireclay Brick DN18 | ||

Physical Properties: | ||

Refractoriness | ℃ | 1750 |

Permanent Linear Change(1450℃×2h)% | % | -0.4~0 |

Apparent Porosity, % | % | ≤18 |

Cold Crushing Strength | Mpa | ≥48 |

Refractoriness Under Load (T0.6) | ℃ | 1400 |

Thermal Expansion at 1000℃, | % | - |

Density | g/cm3 | ≥2.25 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥42 |

Fe2O3 | % | ≤1.8 |

Note: | ||

Feature of Low Porosity Fireclay Brick DN18

Resistant to thermal shock, abrasion, chemical attack

High ability for anti-abrasion during work

Low shrinkage degree under high temperature so as to maintaining integrity of the furnace lining

Low apparent porosity, and low Fe2O3 content to reduce the carbon deposit in the blowhole and avoid the bricks broken in case of expansion

Applications of Low Porosity Fireclay Brick DN18

Low Porosity Fireclay Brick DN18 is mainly used in glass furnace.

- Q: how heavy are boiler of six tons plus refractory bricks?

- The total weight is about 60 tons, 6 tons of bulk boiler steel, insulation materials, sealing materials, refractory material

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of brick has the highest refractory temperature?

- It depends. if high alumina brick is used in kiln, its temperature is above 1700 degree, clay brick is between 1500 degree to 1750 degree, magnesia bricks and magnesia-chrome bricks are about 1500 degree to 1650 degree.

- Q: What is the size of mechanism brick and general refractory brick?

- The ordinary refractory brick is 230mm long, 53mm thick; red brick is 240mm long, 115mm wide, 65mm thick,

- Q: What's the price of clay bricks?

- Clay brick in the fast price of 2.4 yuan or so, the price of 650-800 yuan per ton. Mainly depends on the amount of aluminum. Clay brick consists of heavy clay brick and light clay brick.

- Q: What raw materials are used for making refractory bricks

- That is silicon aluminum refractory brick/, it can be divided into five types:thermal insulation refractory brick, alkaline series refractory brick, refractory brick containing zirconium, carbonaceous refractory brick/. Refractory bricks are divided according to the ingredient of refractory. Refractory bricks are generally made from refractory clay (kaolin) or other refractory materials.

- Q: can castable refractory replace refractory bricks in rotary?kiln?

- The heat produced in the welding process will cause local deformation of the rotary kiln, which will affect the dynamic balance, and the construction difficulty in the middle position of the rotary kiln is much larger than that of the refractory bricks. Moreover, the construction quality is not easy to ensure, generally only replace the refractory brick in the kilneye, because the construction of the castable refractory need to weld the anchor

- Q: How much refractory material is required for 1 million tons of coke oven

- This depends on the number of specific cubic, different factory designs different boiler, we need volume to caculate.

- Q: What is the main use of refractory brick?

- Refractory bricks are mostly used as furnace lining amd air heating furnace in high temperature industry Such as the iron and steel industry blast furnace, colored reverberatory furnace, converter

- Q: How to make the adhesion between refractory brick and the inner wall of the boiler more firm?

- The hook structure, or masonry concrete beams.

- Q: What is the raw material for the production of refractory bricks?

- Refractory raw material, sodium silicate as a binder, and lightweight aggregate, magnesium sand, magnesia calcium. Magnesium Oxide, bauxite, and then lightly burn: Hard refractory clinker

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 83 Million |

| Main Markets | North America;Eastern Asia;Southeast Asia;Western Europe;Middle East;Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Fireclay Brick - Low Porosity DN18

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords