Fireclay Brick - High Density for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

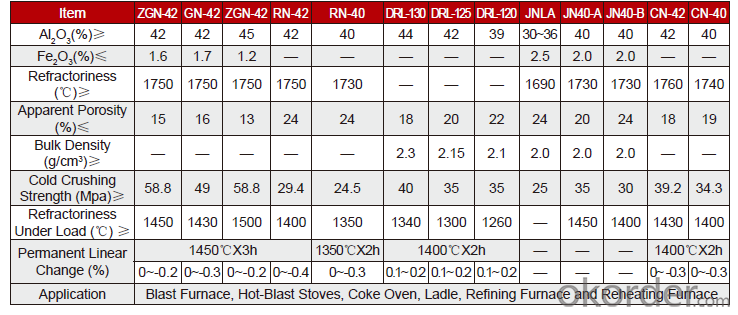

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Whether the cement kiln refractory bricks belong to hazardous waste or not?

- No, there is no harmful gas produced, and it will not pollute the ground.

- Q: What is the advantage for ceramic fiber material compared with refractory brick?

- Heat capacity; excellent thermal shock resistance, good chemical stability, bearing sudden cooling and heating, without oven heating and cooling ,high speed, energy saving, is 1/8 of refractory brick, construction is simple. ceramic fiber materials and refractory brick belong to refractory insulation materials; low thermal conductivity: Low bulk density, ceramic fiber material is a new type of lightweight thermal insulation material, is one of the 10 points of lightweight refractory brick,

- Q: What is the difference between clay brick, glazed tile and brick?

- The whole brick is made of rock debris and is pressed by high pressure. After the surface is polished, the hardness can be compared with the stone, the water absorption rate is lower, and the abrasion resistance is good. The surface of the brick is not glazed, and the material of the front and the back is consistent with the color and lustre, hence the name. Although there are seepage flower, brick and other species, but relatively speaking, its color than non glazed tile. Most of the antiskid bricks are all kinds of bricks.

- Q: What are the specifications of clay brick and cement brick construction?

- 95 bricks are standard bricks. Specification: 95 240*115*53mm85: 216*105*43mm: brick brick brick, artificial small bulk building, divided brick (clay brick) and non sintered brick (sand lime brick, fly ash brick etc.), commonly known as brick.

- Q: When using high alumina refractory brick, what are the reasons leading to the decline of the performance of high alumina brick?

- The excess air coefficient is controlled in 1, in order to prevent producing water cracks in the production of high aluminum refractory brick from, control the water absorption of 2 grade clinker of bauxite with high alumina below 4%-5%. 1-1,the water absorption of the tube mill should also be controlled below 6%, and adjust thermotechnical, making the high alumina refractory brick burning be in the stable weak oxidizing atmosphere. should be 2

- Q: What can be applied to the burned refractory brick to resist heat shock?

- Acidic refractory material use monox as the main component, among which cilica brick and clay brick are commonly used. Silica brick is silicious product containing monox more than 93%, whose raw materials include silica, waste silica brick scrap and etc. The acid resistance of slag erosion ability is good, and the softening temperature under a fixed load is high. The volume won't shrink after repeated burning, but even a slight expand; but it is vulnerable to the erosion of basic slag, and has low thermal shock resistance. The silica brick is mainly used for coke oven, glass melting furnace, acid hearth furnace and other thermal equipments. Clay brick uses refractory clay as the main raw material, containing 30% to 46% of aluminuum oxide, belong to weakly acidic refractories. It has good heat shock resistance and corrosion stability to acid slag, and it's widely used. Neutral refractory materials use aluminum oxides, chromium hemitrioxides or carbons as the main components. Corundum products containing more than 95% of alumina is a kind of high quality refractory material with wide application.

- Q: What are the advantages and disadvantages of clay bricks?

- Disadvantages of clay bricks1., since the majorCompared with other masonry materials, the weight of the clay brick is relatively large, so the structure needs to bear heavy deadweight, and the cost of the building increases. 2., poor sound insulation effectSound travels to the clay brick, because of its low porosity, without isolation of sound, sound decibel little drop, while other building materials such as now used more concrete block filling the void ratio is large, sound insulation effect is obvious.3, environmental destructionBecause clay bricks are mainly sintered by excavation soil, soil erosion and damage to vegetation have resulted in soil erosion and serious damage to the environment. Therefore, the country is gradually stopping the project to use clay bricks.

- Q: does 90m high reinforced concrete chimney need firebrick?

- The chimney need firebricks or casting fire or acid resisitant concrete after casting, one aim is to resist high temperature, then is to resist acid corrosion. there is a variety of models of the refractory brick , you can refer to the installation quota.

- Q: What material is good of refractory bricks?

- It can also be divided into a variety of kinds, it mainly depends on where it is used, each has its own advantages, neutral three categories of refractory bricks have a variety of materials

- Q: what type of refractory bricks does TZ-3 stands for ?

- Z stands for the straight brick, T stands for general brick. general straight shaped standard brick, -3 is the length, specification is 230*114*65 (mm)

Send your message to us

Fireclay Brick - High Density for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords