All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

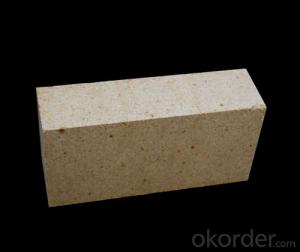

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials resist thermal expansion and contraction?

Refractory materials resist thermal expansion and contraction due to their unique composition and structure. They are made from materials with low coefficients of thermal expansion, which means that they do not expand or contract significantly when exposed to high temperatures. Additionally, refractory materials are designed to have high thermal conductivity, which allows them to efficiently transfer heat and prevent the buildup of thermal stress. This combination of low thermal expansion and high thermal conductivity enables refractory materials to withstand extreme temperature changes without cracking or breaking.

What are the refractory materials used in the pharmaceutical industry?

Refractory materials used in the pharmaceutical industry include alumina, zirconia, silica, and graphite. These materials are chosen for their high temperature resistance, chemical inertness, and ability to withstand harsh conditions in pharmaceutical processes such as high-temperature furnaces and reactors.

What is the role of refractory materials in the automotive industry?

Refractory materials play a crucial role in the automotive industry by providing high-temperature resistance and thermal insulation in various applications. These materials are used to line the combustion chambers, exhaust systems, and catalytic converters, as they can withstand extreme heat generated by the engine and help optimize its performance. Additionally, refractory materials are used in the production of brake pads and clutch plates, ensuring durability and heat dissipation. Overall, refractory materials contribute to the efficiency, safety, and longevity of automotive components operating under high-temperature conditions.

Wholesale Refractory Materials from supplier in Azerbaijan

Whether you require refractory bricks, castables, mortars, or other refractory products, we have a wide range of high-quality options available. Our team of experts can assist you in selecting the most suitable materials for your specific application, taking into account factors such as temperature, chemical resistance, and durability.

In addition to supplying refractory materials, we also offer value-added services such as installation supervision and post-sales support. Our technical team can provide guidance and assistance throughout the entire project, ensuring that your refractory materials are properly installed and maintained for optimal performance.

At CNBM, we prioritize customer satisfaction and are committed to delivering timely and reliable solutions. Our strong global network enables us to source and deliver refractory materials efficiently, ensuring that your projects stay on schedule.

Contact us today to discuss your refractory materials requirements in Azerbaijan. We look forward to partnering with you and providing the highest quality products and services for your projects.

In addition to supplying refractory materials, we also offer value-added services such as installation supervision and post-sales support. Our technical team can provide guidance and assistance throughout the entire project, ensuring that your refractory materials are properly installed and maintained for optimal performance.

At CNBM, we prioritize customer satisfaction and are committed to delivering timely and reliable solutions. Our strong global network enables us to source and deliver refractory materials efficiently, ensuring that your projects stay on schedule.

Contact us today to discuss your refractory materials requirements in Azerbaijan. We look forward to partnering with you and providing the highest quality products and services for your projects.

Hot Search

- Monolithic Refractories in Nepal

- Ceramic Fiber Products in South Korea

- Refractory Bricks in Eritrea

- Raw Materials For Refractory in Somalia

- Monolithic Refractories in British

- Refractory Bricks in Chile

- Raw Materials For Refractory in Tanzania

- Monolithic Refractories in Austria

- Refractory Bricks in Monaco

- Raw Materials For Refractory in Ghana