All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

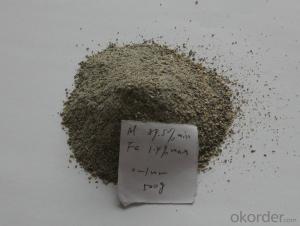

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Discuss the role of fused cast chrome corundum in refractories.

Fused cast chrome corundum plays a significant role in refractories due to its exceptional properties. It is a high-quality material that is widely used in the production of refractory bricks, particularly in areas that require high resistance to extreme temperatures, corrosion, and erosion. Its fused nature ensures excellent thermal stability, making it suitable for applications in glass manufacturing, steelmaking, and other high-temperature environments. Additionally, its high chrome oxide content enhances its resistance to chemical attacks and contributes to its durability. Overall, fused cast chrome corundum is a crucial component in refractories, providing superior performance and longevity in demanding industrial settings.

How is mica obtained and processed for refractory use?

Mica is obtained through mining, primarily from large-scale open-pit or underground mines. Once mined, it undergoes a series of processing steps to obtain suitable mica flakes for refractory use. The processing involves crushing, grinding, and micronizing the mica ore to reduce its particle size and remove impurities. This is followed by various purification techniques such as froth flotation, magnetic separation, and gravity separation to enhance the quality and purity of the mica flakes. After purification, the mica flakes are typically subjected to heat treatment to improve their refractory properties, making them suitable for applications in high-temperature environments.

What are the refractory raw materials used in lining ladle sliding gates?

The refractory raw materials commonly used in lining ladle sliding gates are usually magnesia-based materials, such as magnesia carbon bricks or magnesia alumina carbon bricks. These materials have excellent resistance to high temperatures and chemical corrosion, making them ideal for lining ladle sliding gates in steelmaking processes.

Wholesale Raw Materials For Refractory from supplier in Somalia

Some of the raw materials for refractory products that we supply include:

1. Fireclay: Fireclay is a type of clay that is highly resistant to high temperatures. It is used in the manufacturing of firebricks, which are used to line furnaces, kilns, and other high-temperature applications.

2. High Alumina Refractory Bricks: These bricks are made from high-grade alumina and are used in applications that require high heat resistance, such as steelmaking, glassmaking, and cement production.

3. Magnesia Carbon Bricks: These bricks are made from a combination of magnesia and carbon and are highly resistant to corrosion and erosion. They are used in industries such as steelmaking, non-ferrous metal production, and cement manufacturing.

4. Insulating Firebricks: Insulating firebricks are lightweight bricks that have excellent insulating properties. They are used in applications that require insulation, such as in the construction of kilns, furnaces, and thermal systems.

5. Refractory Castables: Refractory castables are mixtures of refractory aggregates, binders, and additives. They are used to create monolithic linings in various high-temperature applications, such as in furnaces, boilers, and incinerators.

In addition to supplying these raw materials, we also provide sales support, including quotations and technical support services. Our team of experts is well-versed in the properties and applications of refractory materials, and we can assist you in selecting the right materials for your specific projects.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide convenient one-stop procurement services in Somalia. Our extensive product portfolio and market expertise allow us to contribute effectively to the success of your projects. Whether you require small quantities or bulk orders, we are committed to delivering high-quality raw materials for refractory products to meet your needs in Somalia.

1. Fireclay: Fireclay is a type of clay that is highly resistant to high temperatures. It is used in the manufacturing of firebricks, which are used to line furnaces, kilns, and other high-temperature applications.

2. High Alumina Refractory Bricks: These bricks are made from high-grade alumina and are used in applications that require high heat resistance, such as steelmaking, glassmaking, and cement production.

3. Magnesia Carbon Bricks: These bricks are made from a combination of magnesia and carbon and are highly resistant to corrosion and erosion. They are used in industries such as steelmaking, non-ferrous metal production, and cement manufacturing.

4. Insulating Firebricks: Insulating firebricks are lightweight bricks that have excellent insulating properties. They are used in applications that require insulation, such as in the construction of kilns, furnaces, and thermal systems.

5. Refractory Castables: Refractory castables are mixtures of refractory aggregates, binders, and additives. They are used to create monolithic linings in various high-temperature applications, such as in furnaces, boilers, and incinerators.

In addition to supplying these raw materials, we also provide sales support, including quotations and technical support services. Our team of experts is well-versed in the properties and applications of refractory materials, and we can assist you in selecting the right materials for your specific projects.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide convenient one-stop procurement services in Somalia. Our extensive product portfolio and market expertise allow us to contribute effectively to the success of your projects. Whether you require small quantities or bulk orders, we are committed to delivering high-quality raw materials for refractory products to meet your needs in Somalia.

Hot Search

- Monolithic Refractories in South Korea

- Ceramic Fiber Products in Slovenia

- Refractory Bricks in Singapore

- Raw Materials For Refractory in Nicaragua

- Refractory Bricks in Hungary

- Monolithic Refractories in Vietnam

- Refractory Bricks in Djibouti

- Raw Materials For Refractory in Swaziland

- Monolithic Refractories in Cuba

- Refractory Bricks in Latvia