All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

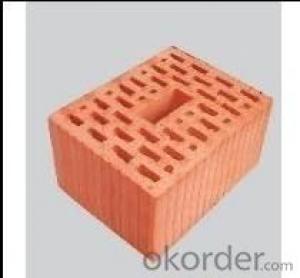

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can refractory bricks be used in the construction of boilers for coal combustion?

Yes, refractory bricks can be used in the construction of boilers for coal combustion. Refractory bricks are designed to withstand high temperatures and are commonly used in industries such as metallurgy, cement, and power generation. In coal-fired boilers, where temperatures can reach several hundred degrees Celsius, refractory bricks are essential to line the combustion chamber and protect the boiler walls from the intense heat produced during coal combustion.

Can refractory bricks be used in petrochemical plants?

Yes, refractory bricks can be used in petrochemical plants. These bricks are designed to withstand high temperatures and harsh chemical environments, making them ideal for lining furnaces, reactors, and other equipment in petrochemical plants. They provide insulation, erosion resistance, and help maintain the structural integrity of the plant's equipment.

Can refractory bricks be used in environments with high levels of moisture?

No, refractory bricks cannot be used in environments with high levels of moisture. They are designed to withstand high temperatures and harsh conditions, but moisture can cause them to deteriorate and lose their strength and insulation properties.

What are the alternatives to traditional refractory bricks?

Some alternatives to traditional refractory bricks include ceramic fibers, castables, and refractory coatings. These materials offer similar heat resistance and insulation properties but are often easier to install and maintain. Additionally, there are newer technologies such as refractory composites and monolithic refractories that provide enhanced performance and durability in high-temperature applications.

What are the common refractory brick shapes used in carbon black production?

The common refractory brick shapes used in carbon black production include straight bricks, arch bricks, and wedge bricks.

Wholesale Refractory Bricks from supplier in Algeria

Our Refractory Bricks are made from high-quality raw materials and manufactured to the highest industry standards, ensuring durability and reliability. We offer a wide range of bricks, including fire clay bricks, high alumina bricks, silica bricks, and magnesia bricks, suitable for various applications such as furnace linings, kilns, and incinerators.

In addition to supplying Refractory Bricks, we also provide customization services to meet your specific project requirements. Our team of experts can assist you in selecting the right type of bricks, determining the optimal brick composition, and designing the most efficient bricklaying patterns. We understand the importance of cost-effectiveness and strive to offer competitive prices without compromising on quality.

Our technical support team is available to provide guidance and assistance throughout your project, from initial consultations to post-sales support. We understand the unique challenges of working in the Algerian market and can offer valuable insights and expertise to ensure the success of your projects. Our goal is to build long-term partnerships with our customers, providing reliable and efficient solutions for all your Refractory Bricks needs.

Contact us today to learn more about our products and services. We are committed to delivering the highest level of customer satisfaction and look forward to serving you in Algeria.

In addition to supplying Refractory Bricks, we also provide customization services to meet your specific project requirements. Our team of experts can assist you in selecting the right type of bricks, determining the optimal brick composition, and designing the most efficient bricklaying patterns. We understand the importance of cost-effectiveness and strive to offer competitive prices without compromising on quality.

Our technical support team is available to provide guidance and assistance throughout your project, from initial consultations to post-sales support. We understand the unique challenges of working in the Algerian market and can offer valuable insights and expertise to ensure the success of your projects. Our goal is to build long-term partnerships with our customers, providing reliable and efficient solutions for all your Refractory Bricks needs.

Contact us today to learn more about our products and services. We are committed to delivering the highest level of customer satisfaction and look forward to serving you in Algeria.

Hot Search

- Monolithic Refractories in Mozambique

- Ceramic Fiber Products in India

- Refractory Bricks in Chile

- Raw Materials For Refractory in Brazil

- Ceramic Fiber Products in Guinea

- Raw Materials For Refractory in Togo

- Monolithic Refractories in Australia

- Ceramic Fiber Products in Laos

- Refractory Bricks in Angola

- Raw Materials For Refractory in Ethiopia