All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the main factors that affect the corrosion resistance of electrolytic tinplate coil in alkaline environments?

The main factors that affect the corrosion resistance of electrolytic tinplate coil in alkaline environments include the composition and thickness of the tin coating, the pH level of the alkaline environment, the presence of corrosive ions or chemicals, the temperature, and the duration of exposure to the alkaline environment.

What are the common surface coatings applied to electrolytic tinplate coil for anti-corrosion properties?

The common surface coatings applied to electrolytic tinplate coil for anti-corrosion properties include tin oxide, chromium oxide, and organic coatings such as lacquers or polymer films.

What is the maximum coil diameter of electrolytic tinplate coil?

The maximum coil diameter of electrolytic tinplate coil is typically determined by the manufacturer and can vary depending on the specific requirements and capabilities of the production line. However, in general, the maximum coil diameter for electrolytic tinplate coil is around 2,000 millimeters (78.7 inches).

What are the common defects that can occur in electrolytic tinplate coil?

Some common defects that can occur in electrolytic tinplate coils include tin oxide spots, tin whiskers, black specks, pinholes, and edge damage.

How does the coil handle chemical resistance?

The coil is designed to handle chemical resistance effectively. It is typically made from materials such as stainless steel or other corrosion-resistant alloys, which can withstand exposure to various chemicals without deteriorating or reacting. Additionally, the coil's construction and design ensure tight sealing and prevent leakage, minimizing the risk of chemical damage. Overall, the coil's robust materials and construction make it highly resistant to chemicals, making it suitable for a wide range of applications where chemical compatibility is required.

Wholesale Electrolytic Tinplate Coil from supplier in Algeria

With our specialization in supplying Electrolytic Tinplate Coils to Algeria, we offer a comprehensive range of services to meet your needs. Whether you require sales assistance, quotations, or technical support, we are here to help. As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide you with a seamless procurement experience.

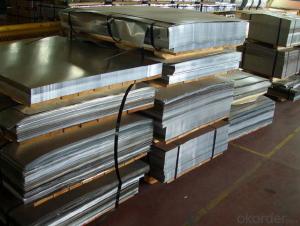

Our Electrolytic Tinplate Coils are of the highest quality and are suitable for various applications. We have a wide range of products available to cater to different requirements. Whether you need tinplate coils for packaging, canning, or any other purpose, we have the right solution for you.

Our years of experience and market development in Algeria have given us valuable insights and knowledge about the local industry. We understand the specific requirements and challenges of the Algerian market, and we can offer you expert advice and support for your projects.

By choosing us as your supplier, you can leverage our experience and expertise to enhance your ventures in Algeria. We are committed to providing you with top-notch products and services that meet your expectations and contribute to the success of your projects.

Explore our offerings today and let us be your trusted partner for Electrolytic Tinplate Coils in Algeria. Contact us for more information or to discuss your specific requirements.

Our Electrolytic Tinplate Coils are of the highest quality and are suitable for various applications. We have a wide range of products available to cater to different requirements. Whether you need tinplate coils for packaging, canning, or any other purpose, we have the right solution for you.

Our years of experience and market development in Algeria have given us valuable insights and knowledge about the local industry. We understand the specific requirements and challenges of the Algerian market, and we can offer you expert advice and support for your projects.

By choosing us as your supplier, you can leverage our experience and expertise to enhance your ventures in Algeria. We are committed to providing you with top-notch products and services that meet your expectations and contribute to the success of your projects.

Explore our offerings today and let us be your trusted partner for Electrolytic Tinplate Coils in Algeria. Contact us for more information or to discuss your specific requirements.