All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

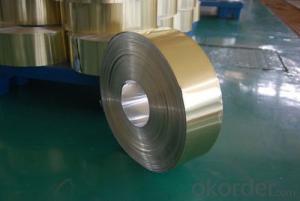

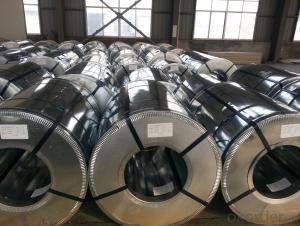

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do stainless steel coils resist corrosion from chemicals?

Stainless steel coils resist corrosion from chemicals due to their high levels of chromium content, which forms a protective layer on the surface of the metal. This layer, known as the passive film, acts as a barrier against corrosive agents, preventing them from coming into direct contact with the steel. Additionally, stainless steel coils may contain other alloying elements such as nickel and molybdenum, which further enhance their corrosion resistance properties.

What are the different types of slitting techniques for stainless steel coil?

There are several different types of slitting techniques for stainless steel coil, including rotary shear slitting, loop slitting, and oscillating slitting. Rotary shear slitting involves using a set of rotating knives to cut the stainless steel coil into narrower strips. Loop slitting involves passing the coil through a loop to create tension and then cutting it using a straight knife or rotary shear. Oscillating slitting utilizes a stationary knife and a vibrating blade to make the cuts. Each technique has its own advantages and is chosen based on the specific requirements of the stainless steel coil.

What are the safety precautions when handling stainless steel coil?

When handling stainless steel coil, it is important to follow several safety precautions. Firstly, it is crucial to wear appropriate personal protective equipment such as gloves and safety glasses to protect against cuts and potential eye injuries. Secondly, ensure that the coil is properly secured and stable during handling to prevent it from rolling or falling. Additionally, use caution when using tools or equipment near the coil to avoid accidental injury. Finally, be aware of the weight and size of the coil to prevent strains or other musculoskeletal injuries.

How does the coil surface finish of a stainless steel coil affect its appearance?

The coil surface finish of a stainless steel coil greatly affects its appearance. A smooth and polished surface finish enhances the aesthetic appeal of the stainless steel coil, making it look glossy and reflective. On the other hand, a rough or brushed surface finish gives the stainless steel coil a more industrial or rustic appearance. The surface finish can also affect the visibility of fingerprints, smudges, and scratches, with a polished finish being more prone to showing imperfections compared to a textured finish. Ultimately, the choice of coil surface finish depends on the desired look and application of the stainless steel coil.

What is the maximum length of a stainless steel coil?

The maximum length of a stainless steel coil can vary depending on the specific grade and type of stainless steel, as well as the manufacturing capabilities of the supplier. However, in general, stainless steel coils can be produced in lengths ranging from a few meters to several kilometers.

Wholesale Stainless Steel Coil from supplier in Algeria

We are a Stainless Steel Coil supplier serving the Algeria, mainly engaged in the sale, quotation, and technical support services of various Stainless Steel Coil products in the Algeria region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Stainless Steel Coil procurement services in the Algeria. Not only do we have a wide range of Stainless Steel Coil products, but after years of market development in the Algeria, we can also provide valuable experience for your projects.