All Categories

- - Steel Wire Rod

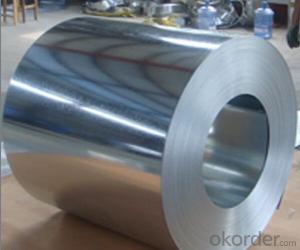

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What role does coil packaging and banding play in secure coil transportation?

Coil packaging and banding play a crucial role in secure coil transportation by ensuring the coils are properly protected and secured during transit. It helps prevent damage, shifting, or movement of the coils, reducing the risk of accidents or injuries. The packaging materials, such as shrink wrap or stretch film, provide a protective barrier against moisture, dust, and other external elements. Banding, on the other hand, holds the coils tightly together, preventing them from unwinding or unraveling during transportation. Overall, coil packaging and banding contribute to the safe and secure transport of coils, maintaining their integrity and quality.

What measures are in place to prevent coil flatness issues when producing metal office equipment?

There are several measures in place to prevent coil flatness issues when producing metal office equipment. Firstly, manufacturers use high-quality raw materials and ensure that the coil has a uniform thickness and proper tempering. Additionally, advanced coil processing techniques such as leveling, tension leveling, and precision rolling are employed to maintain flatness. Regular quality checks and inspections during the production process help identify any potential flatness issues early on, allowing for immediate corrective actions. Overall, a combination of material selection, processing techniques, and quality control measures ensures that coil flatness issues are minimized in the production of metal office equipment.

How are steel coils prepared for the manufacturing of automotive parts?

Steel coils are prepared for the manufacturing of automotive parts through a series of steps. First, the coils are uncoiled and flattened to remove any bends or twists. They are then cut into the desired lengths using specialized machinery. The cut pieces are then shaped or molded using various techniques such as stamping, bending, or rolling to create the specific automotive part. These parts are then further processed, such as heat treatment or surface finishing, to enhance their strength and durability. Finally, the prepared parts are assembled and integrated into the manufacturing process of automobiles.

Wholesale Steel Coils from supplier in Nicaragua

We are a Steel Coils supplier serving the Nicaragua, mainly engaged in the sale, quotation, and technical support services of various Steel Coils products in the Nicaragua region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Coils procurement services in the Nicaragua. Not only do we have a wide range of Steel Coils products, but after years of market development in the Nicaragua, we can also provide valuable experience for your projects.