All Categories

- - Steel Wire Rod

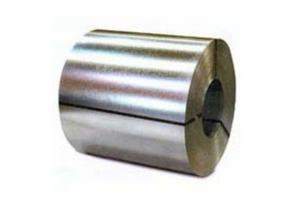

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

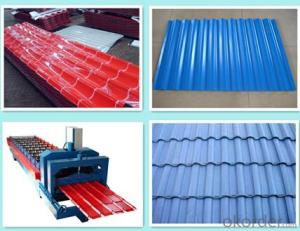

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the key properties of cold-rolled steel that make it suitable for advanced medical devices and implants?

Cold-rolled steel possesses several key properties that make it suitable for advanced medical devices and implants. Firstly, it offers excellent strength and durability, ensuring the longevity and reliability of the medical devices. Additionally, cold-rolled steel has a high degree of corrosion resistance, which is crucial for maintaining the integrity and sterility of the implants within the human body. Furthermore, this type of steel can be easily shaped and formed into complex designs, allowing for the creation of intricate and customized medical devices. Lastly, cold-rolled steel is biocompatible, meaning it does not elicit adverse reactions or toxicity in the body, making it a safe and reliable material for medical applications.

Can you explain the cold-rolling process in detail?

Sure! The cold-rolling process is a metalworking technique used to shape and refine metal sheets or strips. It involves passing the metal through a series of rollers at room temperature, which reduces the thickness and increases the hardness and strength of the material.

First, the metal is cleaned and prepared to remove any impurities or surface contaminants. Then, it is fed into the first set of rollers, which apply pressure to compress and elongate the metal. The metal is then passed through subsequent rollers, each set reducing the thickness of the material further.

Cold-rolling has several advantages over hot-rolling, such as improved dimensional accuracy, better surface finish, and increased strength. Additionally, the process can be repeated multiple times to achieve the desired thickness or properties.

Overall, the cold-rolling process is a critical step in the production of various metal products, including automotive parts, construction materials, and consumer goods, as it enhances the material's mechanical properties and improves its performance.

What is the typical thickness range for cold-rolled steel?

The typical thickness range for cold-rolled steel is between 0.4 to 6 millimeters.

What is the typical lead time for ordering cold-rolled steel?

The typical lead time for ordering cold-rolled steel can vary depending on factors such as the supplier, quantity, and current market conditions. However, it is common to expect lead times ranging from a few weeks to a couple of months.

Wholesale Cold Rolled Steel from supplier in Nicaragua

We are a Cold Rolled Steel supplier serving the Nicaragua, mainly engaged in the sale, quotation, and technical support services of various Cold Rolled Steel products in the Nicaragua region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Cold Rolled Steel procurement services in the Nicaragua. Not only do we have a wide range of Cold Rolled Steel products, but after years of market development in the Nicaragua, we can also provide valuable experience for your projects.