All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the methods for coating aluminum coils for corrosion resistance?

There are various methods for coating aluminum coils for corrosion resistance. Some common methods include anodizing, painting, powder coating, and coil coating. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrolytic process. Painting involves applying a layer of paint onto the surface, which acts as a barrier against corrosion. Powder coating involves electrostatically applying a dry powder onto the surface, which is then cured to form a protective coating. Coil coating is a continuous process where a coating is applied to the aluminum coil before it is formed into the desired product, providing long-lasting corrosion resistance.

What are the applications of aluminum coils in the production of aluminum staircases?

Aluminum coils are widely used in the production of aluminum staircases due to their excellent properties. The coils are utilized for various applications such as manufacturing the structural components of the staircase, including the steps and the framework. The malleability and durability of aluminum make it an ideal material for constructing lightweight and corrosion-resistant staircases. Additionally, the coils can be easily formed and shaped into the desired designs, allowing for flexibility and customization in staircase production. Overall, aluminum coils play a crucial role in ensuring the strength, aesthetics, and longevity of aluminum staircases.

How are aluminum coils used in the production of heat exchangers?

Aluminum coils are used in the production of heat exchangers as they offer excellent thermal conductivity and corrosion resistance. These coils are formed into a specific shape and structure to allow for efficient heat transfer between fluids. The aluminum material allows for quick and effective heat dissipation, making it an ideal choice for heat exchangers used in various industries such as HVAC, refrigeration, and automotive.

Can aluminum coils be used in the production of lighting fixtures?

Yes, aluminum coils can be used in the production of lighting fixtures. Aluminum is a commonly used material in the manufacturing industry due to its lightweight, corrosion-resistant, and malleable properties. It is often used for various components, including the housing, reflectors, and heat sinks, in lighting fixtures.

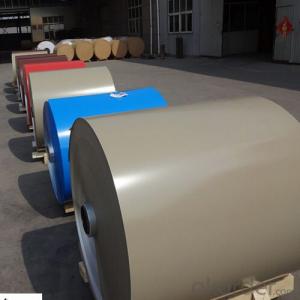

Wholesale Aluminum Coils from supplier in Algeria

Whether you are in the construction, automotive, or packaging industry, our Aluminum Coils can cater to your needs. We offer a variety of grades and thicknesses to suit different applications. Our Aluminum Coils are made from high-quality materials, ensuring durability and longevity.

In addition to supplying Aluminum Coils, we also provide value-added services such as cutting, slitting, and customizing the coils to meet your precise specifications. Our technical team is always ready to assist you with any questions or concerns you may have.

At our company, customer satisfaction is our top priority. We strive to offer competitive prices, prompt delivery, and excellent after-sales service. We understand the importance of building long-term relationships with our customers, and we are committed to meeting your expectations.

If you are looking for a reliable supplier of Aluminum Coils in Algeria, look no further. Contact us today to discuss your requirements and let us provide you with the best solutions for your business.

In addition to supplying Aluminum Coils, we also provide value-added services such as cutting, slitting, and customizing the coils to meet your precise specifications. Our technical team is always ready to assist you with any questions or concerns you may have.

At our company, customer satisfaction is our top priority. We strive to offer competitive prices, prompt delivery, and excellent after-sales service. We understand the importance of building long-term relationships with our customers, and we are committed to meeting your expectations.

If you are looking for a reliable supplier of Aluminum Coils in Algeria, look no further. Contact us today to discuss your requirements and let us provide you with the best solutions for your business.